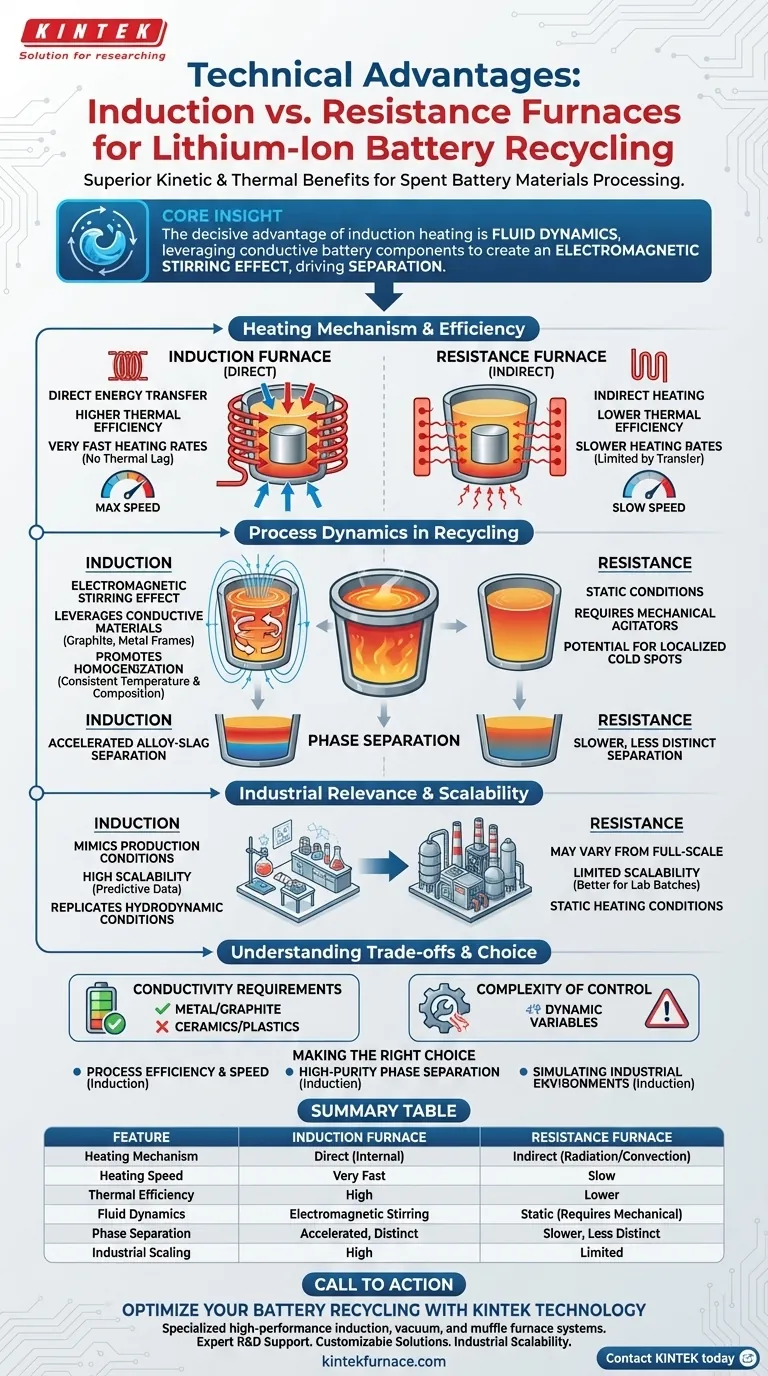

Induction furnaces provide superior kinetic and thermal advantages over resistance furnaces when processing spent lithium-ion battery materials. The primary benefits include significantly faster heating rates, higher thermal efficiency through direct energy transfer, and a unique electromagnetic stirring effect that is critical for material separation.

Core Insight: The decisive advantage of induction heating is not just temperature generation, but fluid dynamics. By leveraging the conductive nature of battery components like graphite and metal, induction creates an electromagnetic stirring effect that physically drives the separation of valuable alloys from waste slag.

The Mechanism of Heating

Direct vs. Indirect Energy Transfer

Resistance furnaces rely on indirect heating. They heat elements which then transfer thermal energy to the crucible and finally to the material via radiation and convection.

Superior Thermal Efficiency

In contrast, induction furnaces offer higher thermal efficiency because they generate heat directly within the metallic materials.

Faster Heating Rates

Because the energy is induced directly into the load, the thermal lag is eliminated. This results in significantly faster heating rates, allowing the system to reach processing temperatures much more quickly than resistance-based alternatives.

Process Dynamics in Battery Recycling

Leveraging Material Composition

Spent battery materials are uniquely suited for induction because they contain significant amounts of graphite and metal frames. These materials are conductive, allowing them to couple effectively with the electromagnetic field.

The Electromagnetic Stirring Effect

The most distinct technical advantage is the generation of an electromagnetic stirring effect. The magnetic field forces movement within the molten pool, which is impossible to achieve in a static resistance furnace without external mechanical agitators.

Promoting Homogenization

This stirring action promotes the homogenization of components within the melt. It ensures that temperature and chemical composition are consistent throughout the mixture, preventing localized cold spots or unreacted pockets.

Accelerated Phase Separation

Crucially, the stirring effect accelerates the separation of the alloy phase from the slag. By keeping the melt dynamic, the induction furnace facilitates the physical settling of heavier metallic alloys while separating them from the lighter waste byproducts.

Industrial Relevance

Mimicking Production Conditions

Data obtained from resistance furnaces can sometimes vary from full-scale operations due to static heating conditions.

Scalability of Data

Using an induction furnace allows researchers and engineers to closely mimic the conditions of large-scale industrial production. This ensures that the separation efficiencies and reaction kinetics observed in the test environment are predictive of real-world plant performance.

Understanding the Trade-offs

Material Conductivity Requirements

Induction heating relies entirely on the material's ability to conduct electricity. While effective for battery waste rich in metals and graphite, it may be less efficient if the feedstock is heavily diluted with non-conductive ceramics or plastics prior to processing.

Complexity of Control

While resistance furnaces provide simple, steady ambient heat, induction furnaces introduce dynamic variables. The stirring effect, while beneficial, introduces kinetic energy that must be managed to prevent crucible erosion or excessive turbulence depending on the specific furnace design.

Making the Right Choice for Your Goal

When selecting a furnace technology for recycling lithium-ion battery materials, consider your specific processing objectives.

- If your primary focus is process efficiency and speed: Choose an induction furnace to exploit direct heating and reduce cycle times.

- If your primary focus is high-purity phase separation: Choose an induction furnace to utilize electromagnetic stirring for cleaner alloy-slag distinctness.

- If your primary focus is simulating industrial environments: Choose an induction furnace to replicate the hydrodynamic conditions found in large-scale smelting operations.

Ultimately, for the specific metallurgy of battery recycling, induction offers a functional advantage by turning the waste material's conductivity into a tool for its own refinement.

Summary Table:

| Feature | Induction Furnace | Resistance Furnace |

|---|---|---|

| Heating Mechanism | Direct (internal heat generation) | Indirect (radiation/convection) |

| Heating Speed | Very Fast (no thermal lag) | Slow (limited by element transfer) |

| Thermal Efficiency | High (energy focused on load) | Lower (energy lost to chamber) |

| Fluid Dynamics | Electromagnetic stirring effect | Static (requires mechanical stirring) |

| Phase Separation | Accelerated alloy-slag separation | Slower, less distinct separation |

| Industrial Scaling | High (mimics large-scale smelting) | Limited (better for small lab batches) |

Optimize Your Battery Recycling with KINTEK Technology

Transitioning from lab-scale testing to industrial-scale lithium-ion battery recycling requires specialized heating solutions that offer both speed and precision. KINTEK provides high-performance induction, vacuum, and muffle furnace systems specifically engineered to handle the unique conductivity of graphite and metallic battery waste.

Our Value to You:

- Expert R&D Support: Our systems are backed by professional manufacturing to ensure your recycling process achieves maximum phase separation and thermal efficiency.

- Customizable Solutions: From CVD systems to rotary and tube furnaces, we tailor our high-temp lab equipment to your specific material needs.

- Industrial Scalability: Achieve consistent homogenization and predictable results that mimic large-scale production environments.

Ready to enhance your material refinement? Contact KINTEK today to discuss how our customizable high-temperature furnaces can accelerate your research and production goals.

Visual Guide

References

- Chen Wang, Hongbin Ling. Extraction of Valuable Metals from Spent Li-Ion Batteries Combining Reduction Smelting and Chlorination. DOI: 10.3390/met15070732

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- What environmental benefits do induction furnaces provide? Achieve Cleaner, Safer Industrial Heating

- Why is an induction furnace equipped with a graphite susceptor necessary? Achieving Precision for Electrical Steel

- What are electric arc furnaces and how do they work? Unlock Efficient Metal Melting Solutions

- What is the role of a vacuum arc furnace in the synthesis of AlCrFeNi HEAs? Achieve High-Purity Material Homogeneity

- What is the role of vacuum arc melting equipment in the preparation of Ti-33Al based alloy button ingots?

- How do vacuum induction furnaces facilitate titanium hydride dehydrogenation? Achieve High-Purity Metal Powder

- What are the advantages of using a Vacuum Induction Melting Furnace over an ordinary open melting furnace? Achieve Purity and Precision in Metal Production

- What is the function of a Vacuum Magnetic-controlled Arc Furnace in AFA alloys? Ensure Purity & Uniformity