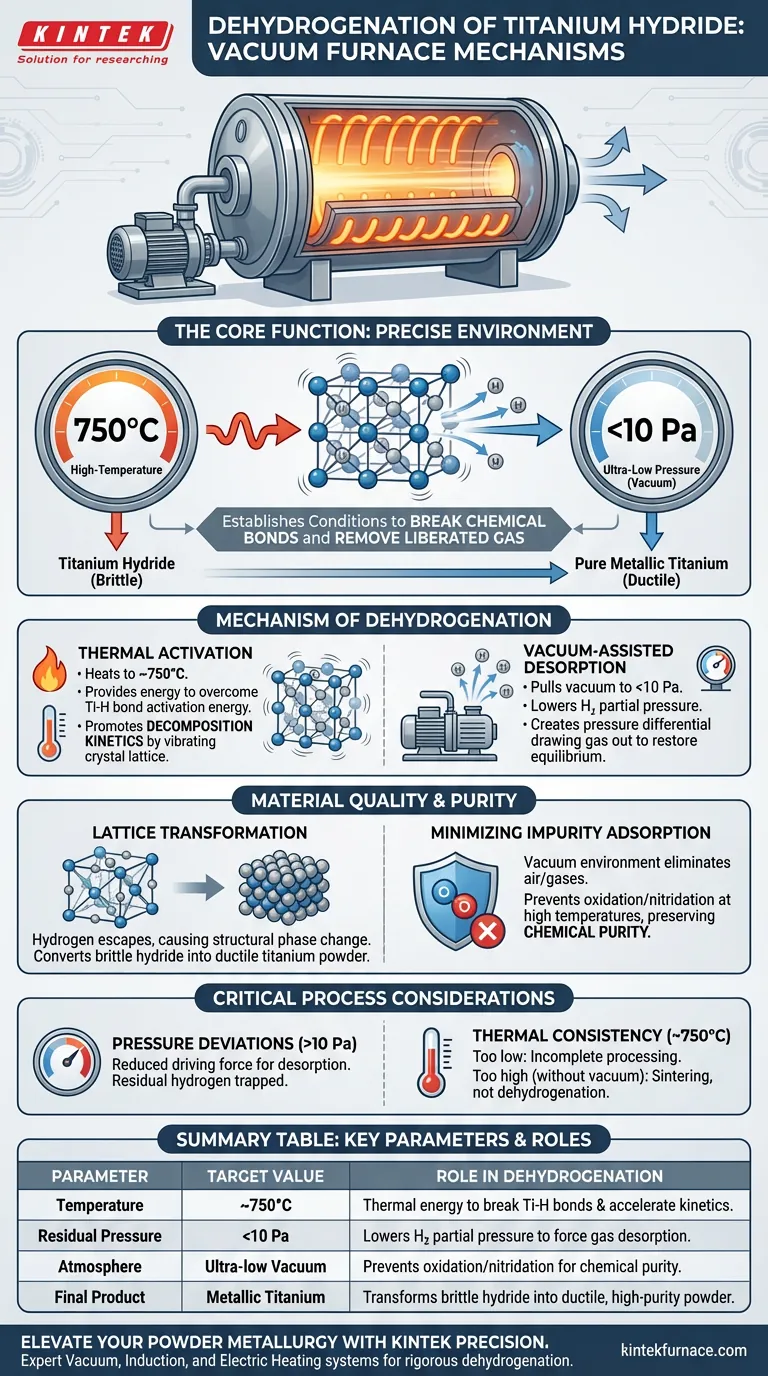

Vacuum induction and electric heating furnaces facilitate the dehydrogenation of titanium hydride by establishing a precise high-temperature, ultra-low pressure environment. By maintaining temperatures at approximately 750°C and reducing residual pressure to below 10 Pa, these systems create the thermodynamic conditions necessary to break chemical bonds. This forces hydrogen atoms to exit the crystal lattice, converting the hydride back into pure metallic titanium.

The core function of these furnaces is to accelerate decomposition kinetics through heat while removing the liberated gas via vacuum, ensuring the final titanium powder retains high chemical purity.

The Mechanism of Dehydrogenation

To understand how these furnaces operate, you must look at the interplay between thermal energy and pressure gradients. The equipment does not simply heat the material; it manipulates the environment to favor the release of hydrogen.

Thermal Activation

The furnaces heat the titanium hydride to approximately 750°C.

At this specific temperature, the thermal energy provided is sufficient to overcome the activation energy of the titanium-hydrogen bond.

This heat promotes decomposition kinetics, vibrating the crystal lattice enough to loosen the hold on hydrogen atoms.

Vacuum-Assisted Desorption

Simultaneously, the system pulls a vacuum to achieve a residual pressure below 10 Pa.

This ultra-low pressure environment lowers the partial pressure of hydrogen surrounding the material.

By creating a significant pressure differential between the hydrogen inside the lattice and the vacuum chamber, the gas is physically drawn out of the material to restore equilibrium.

Material Quality and Purity

Beyond the simple removal of hydrogen, these furnaces are critical for determining the physical and chemical quality of the final product.

Lattice Transformation

As hydrogen escapes, the material undergoes a structural phase change.

The process transforms the brittle titanium hydride structure back into ductile metallic titanium powder.

This relies on the controlled exit of hydrogen atoms from the crystal lattice, leaving behind the pure metal matrix.

Minimizing Impurity Adsorption

The vacuum environment serves a dual purpose: extraction and protection.

By eliminating air and other gases from the chamber, the furnace prevents the titanium from reacting with oxygen or nitrogen at high temperatures.

This preserves chemical purity and minimizes the adsorption of new impurities during the transition.

Critical Process Considerations

While the concept is straightforward, the operational reality involves strict parameter control. Failing to maintain the specific environmental conditions cited can compromise the result.

Sensitivity to Pressure Deviations

If the residual pressure rises above the 10 Pa threshold, the efficiency of hydrogen removal drops significantly.

Higher pressure reduces the driving force for desorption, potentially leaving residual hydrogen trapped within the lattice.

Thermal Consistency

Maintaining the temperature near 750°C is equally vital.

Temperatures that are too low will stall the decomposition kinetics, resulting in incomplete processing.

Conversely, excessive temperatures without adequate vacuum control could lead to sintering of the powder rather than simple dehydrogenation.

Optimizing the Dehydrogenation Process

To achieve the best results with vacuum induction or electric heating furnaces, align your operational parameters with your specific quality goals.

- If your primary focus is Chemical Purity: Prioritize maintaining the vacuum level strictly below 10 Pa to prevent oxidation and impurity adsorption.

- If your primary focus is Process Efficiency: Ensure the temperature is stabilized quickly and consistently at 750°C to maximize decomposition kinetics.

Control the environment precisely, and you ensure the successful reversion of hydride to pure metal.

Summary Table:

| Parameter | Target Value | Role in Dehydrogenation |

|---|---|---|

| Temperature | ~750°C | Provides thermal energy to break Ti-H bonds and accelerate kinetics. |

| Residual Pressure | <10 Pa | Lowers hydrogen partial pressure to force gas desorption from the lattice. |

| Atmosphere | Ultra-low Vacuum | Prevents oxidation/nitridation, ensuring final chemical purity. |

| Final Product | Metallic Titanium | Transforms brittle hydride into ductile, high-purity metal powder. |

Elevate Your Powder Metallurgy with KINTEK Precision

Achieving the perfect balance of temperature and vacuum is critical for the chemical purity of your titanium products. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Vacuum, Induction, and Electric Heating systems designed to meet the rigorous demands of dehydrogenation.

Whether you need standard laboratory units or fully customizable high-temp furnaces for unique industrial scales, KINTEK provides the reliability your research and production deserve.

Ready to optimize your material transformation? Contact our thermal processing experts today to find the perfect solution for your lab.

Visual Guide

References

- Н. П. Черезов, М. И. Алымов. SHS-Hydrogenation, Thermal Dehydrogenation, and Plasma Spheroidization to Produce Spherical Titanium Powders from Titanium Sponge. DOI: 10.3390/alloys3030014

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is an induction gold melting furnace and how does it work? Achieve Purity, Speed, and Efficiency

- How does the controlled cooling environment of a melting furnace affect the microstructure of CoCuMoNiAl alloy ingots?

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- How does induction heating reduce energy costs? Achieve Up to 90% Energy Efficiency

- What role does a Vacuum Induction Melting Furnace play in the production of weather-resistant steel? Precision Engineering

- What is the purpose of maintaining high-purity argon gas in vacuum induction melting? Stabilize Your Steel Composition

- What are the advantages of using a Vacuum Induction Melting furnace for Cr-Si alloys? Superior Uniformity & Purity

- What are the key features of a medium frequency induction furnace? Unlock Faster, Cleaner Metal Processing