At its core, an induction gold melting furnace is a high-efficiency device that uses the principles of electromagnetism to melt gold and other conductive metals. Instead of using an external flame or heating element, it generates a powerful magnetic field that induces an electric current directly within the metal itself, causing it to heat rapidly and melt from the inside out.

An induction furnace is not simply a replacement for a traditional furnace; it is a fundamental shift in heating technology. By using a contactless electromagnetic field to generate heat within the metal, it offers a level of speed, purity, and control that combustion-based methods cannot match.

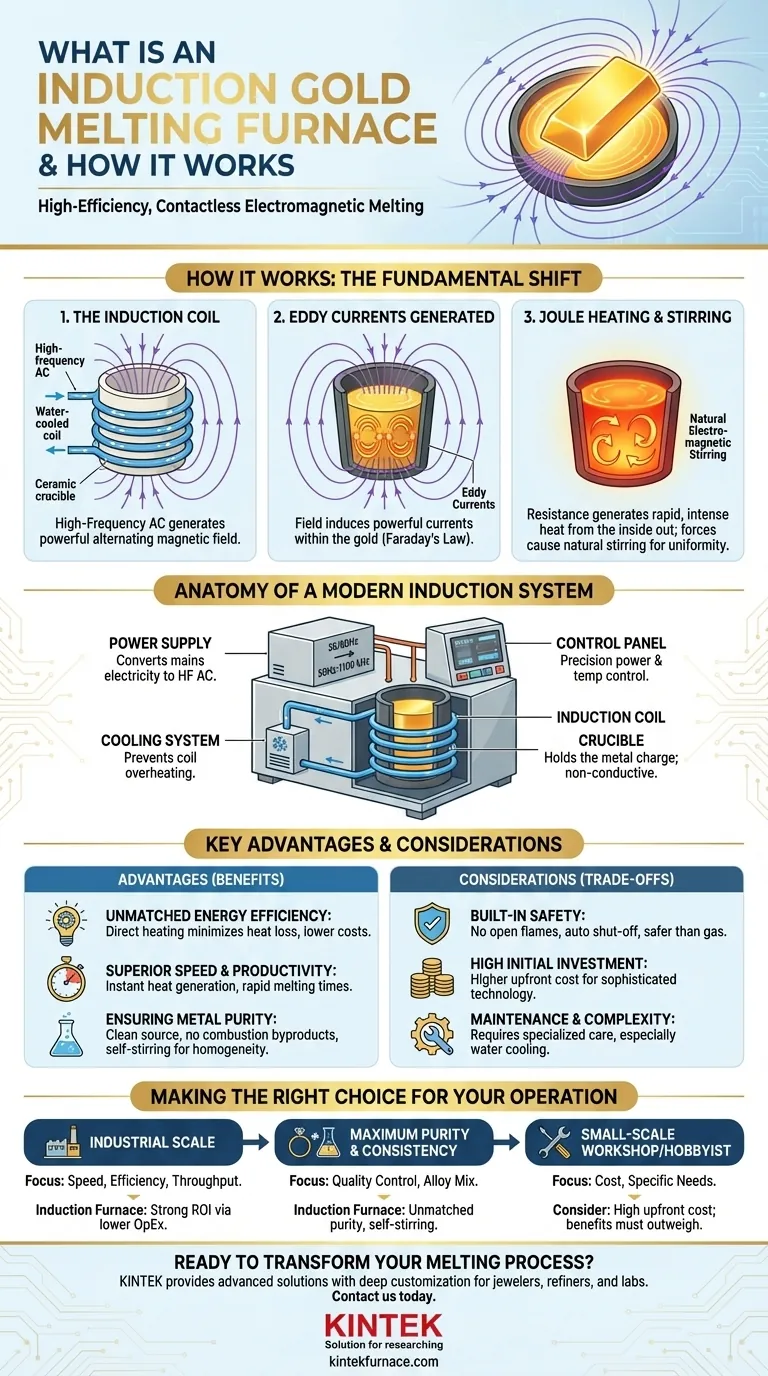

How Induction Melting Actually Works

The process is clean, contained, and based on fundamental physics. It involves generating intense heat without any physical contact between the heat source and the metal.

The Role of the Induction Coil

A high-frequency alternating current (AC) is passed through a water-cooled copper coil. This coil is typically shaped to surround a crucible where the gold is placed.

Passing this current through the coil generates a powerful and rapidly alternating magnetic field in the space within and around the coil.

Generating Heat with Eddy Currents

This dynamic magnetic field penetrates the conductive metal (gold) placed inside the crucible. According to Faraday's law of induction, the changing magnetic field induces circular electric currents within the gold, known as eddy currents.

Because gold has electrical resistance, these powerful eddy currents generate immense heat through a process called Joule heating. This is the same principle that causes any electrical wire to warm up, but amplified dramatically to achieve melting temperatures.

The Inherent Stirring Effect

A secondary benefit of the electromagnetic forces is a natural stirring or agitation of the molten metal. This action ensures a more uniform temperature throughout the melt and helps create a homogenous alloy when mixing metals, improving the final quality of the casting.

Anatomy of a Modern Induction System

A modern induction furnace is an integrated system where each component plays a critical role in delivering a safe and efficient melt.

The Crucible: Containing the Metal

This is the vessel that holds the metal charge. It must be made from a material, like graphite or ceramic, that can withstand extreme temperatures and is not electrically conductive, so it doesn't heat up from the induction field itself.

The Power Supply: The Engine of the System

This is the heart of the furnace. It converts standard mains electricity (e.g., 50/60 Hz) into the high-frequency alternating current (from 50 Hz to 1100 kHz) required to drive the induction coil and generate the magnetic field.

The Cooling System: The Unsung Hero

The massive currents flowing through the copper coil generate significant heat. A closed-loop water cooling system continuously circulates water through the coil to prevent it from overheating and melting, ensuring the system's integrity and longevity.

The Control Panel: Precision at Your Fingertips

Modern furnaces feature sophisticated control panels. These allow operators to precisely regulate power output and monitor temperature, enabling highly repeatable processes and preventing the overheating or vaporization of valuable metal.

Understanding the Key Advantages

The shift to induction melting is driven by clear, measurable benefits over traditional gas or resistance-based furnaces.

Unmatched Energy Efficiency

Induction heating is direct. Nearly all the electrical energy is converted into heat directly within the metal. This minimizes the heat lost to the surrounding environment, resulting in significantly lower energy consumption and reduced operational costs.

Superior Speed and Productivity

Because the heat is generated instantly within the charge, melting times are dramatically reduced. This allows for faster turnaround, increasing productivity for both small jewelers and large-scale industrial operations.

Ensuring Metal Purity

Induction is a "clean" heat source. There are no combustion byproducts like carbon to contaminate the metal. This, combined with the self-stirring action, results in a final product of superior purity and consistency.

Critical Trade-offs and Considerations

While highly effective, induction technology involves trade-offs that are important to understand for any potential user.

Built-in Safety Mechanisms

Compared to open-flame furnaces, induction systems are inherently safer. They eliminate the risks associated with combustible gases and open flames. Modern units are equipped with automatic shut-off systems, over-voltage protection, and thermal monitoring to protect both the operator and the equipment.

The High Initial Investment

The primary trade-off is capital cost. An induction furnace system, with its sophisticated power supply and cooling loop, represents a significantly higher upfront investment compared to a simple gas torch or resistance furnace.

Maintenance and System Complexity

The reliability of an induction furnace hinges on the proper function of all its components, especially the water cooling system. A failure in the cooling loop can lead to catastrophic damage to the induction coil. These systems require more specialized maintenance than their simpler counterparts.

Making the Right Choice for Your Operation

Your optimal choice depends entirely on your specific goals regarding scale, purity, and operational efficiency.

- If your primary focus is industrial-scale production: The speed and energy efficiency of an induction furnace will almost certainly deliver a strong return on the initial investment through lower operational costs and higher throughput.

- If your primary focus is maximum purity and alloy consistency: The clean, contained, and self-stirring nature of induction melting provides a level of quality control that is difficult to achieve with other methods.

- If your primary focus is a small-scale workshop or hobbyist use: The high upfront cost may be a significant barrier unless the specific benefits of speed and purity are critical to your work.

Ultimately, adopting an induction furnace is an investment in precision, efficiency, and safety.

Summary Table:

| Feature | How It Works | Key Benefit |

|---|---|---|

| Induction Heating | A magnetic field induces eddy currents directly in the gold. | Heat is generated instantly from within, ensuring rapid melting and energy efficiency. |

| Contactless Process | The metal is heated without a flame or direct contact. | Eliminates contamination from combustion, guaranteeing superior metal purity. |

| Electromagnetic Stirring | The magnetic field naturally agitates the molten metal. | Creates a homogenous melt and consistent alloy mix for higher-quality results. |

| Precision Control | Sophisticated control panels regulate power and temperature. | Enables repeatable processes and prevents overheating of valuable materials. |

Ready to Transform Your Melting Process with Precision Engineering?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides jewelers, refiners, and research labs with advanced induction melting solutions. Our product line, including Crucible, Vacuum, and Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique production requirements—whether you prioritize industrial-scale throughput or laboratory-grade purity.

Contact KINTEK today to discuss how our induction furnaces can enhance your efficiency, purity, and safety.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys