Vacuum Induction Melting (VIM) offers distinct advantages over arc furnace melting for Chromium-Silicon (Cr-Si) alloys, primarily due to superior process efficiency and material quality. The most significant benefit is the induction-generated electromagnetic stirring, which creates compositional uniformity in a single step, whereas arc furnaces typically require multiple remelting cycles to achieve the same result.

The core advantage of VIM lies in its ability to actively stir the molten metal using eddy currents. This ensures a homogeneous alloy structure without the repetitive labor and energy costs associated with the multiple remelts required by arc furnace processing.

Achieving Compositional Uniformity

The Mechanism of Electromagnetic Stirring

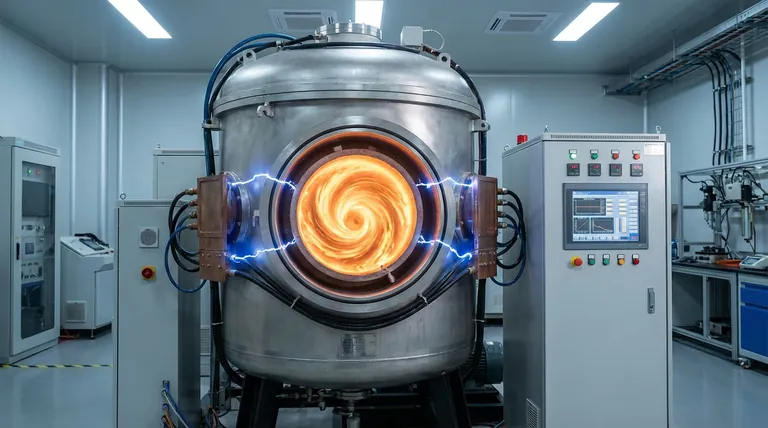

The defining feature of a VIM furnace is the generation of induction-generated eddy currents.

These currents do more than just heat the metal; they create a vigorous, natural stirring action within the melt. This ensures that the Chromium and Silicon are mixed thoroughly and evenly throughout the crucible.

Eliminating Redundant Process Steps

When using an arc furnace, achieving a uniform mixture is often a passive and inconsistent process.

Consequently, operators must often perform multiple remelting steps to guarantee the alloy is homogeneous. VIM eliminates this requirement completely, allowing you to prepare master alloys with high compositional homogeneity in a single melting operation.

Protection and Purity of the Melt

Preventing Oxidative Loss

Silicon is an active element that is prone to oxidation at high temperatures.

The VIM process operates in a controlled vacuum environment. This effectively prevents the oxidative loss of active elements like silicon, ensuring that the final chemical composition matches your intended calculations.

Removal of Impurities

Beyond preserving the alloy's intended elements, the vacuum environment actively assists in purification.

Smelting in a VIM furnace effectively removes volatile impurities that can compromise the alloy's integrity. This results in a cleaner material foundation, which is essential for achieving superior mechanical and thermal performance in the final product.

Understanding the Operational Context

The Necessity of Precision

While VIM offers superior quality, it is a process defined by precise control.

Unlike the more rugged nature of some arc melting operations, VIM requires careful management of the vacuum environment and induction parameters. It is best suited for applications where the cost of the equipment is justified by the strict requirement for high-performance material properties, such as those found in aerospace or power generation.

Making the Right Choice for Your Goal

- If your primary focus is Process Efficiency: VIM is the superior choice because it utilizes electromagnetic stirring to eliminate the time-consuming multiple remelts required by arc furnaces.

- If your primary focus is Chemical Precision: VIM provides the necessary vacuum environment to prevent the loss of active silicon and remove impurities, ensuring the alloy meets exact specifications.

By leveraging the inherent stirring and protective atmosphere of a VIM furnace, you ensure a higher quality Cr-Si alloy with a significantly streamlined production workflow.

Summary Table:

| Feature | Vacuum Induction Melting (VIM) | Arc Furnace |

|---|---|---|

| Mixing Mechanism | Active electromagnetic stirring | Passive mixing |

| Homogeneity | High uniformity in a single melt | Requires multiple remelting cycles |

| Oxidation Control | High (vacuum prevents silicon loss) | Lower (prone to oxidative loss) |

| Purity Level | Volatile impurities removed via vacuum | Higher impurity retention |

| Efficiency | High (streamlined single-step process) | Lower (due to repetitive processing) |

Elevate Your Alloy Production with KINTEK

Precision matters when melting high-performance materials like Chromium-Silicon alloys. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Induction Melting systems and a full range of lab high-temp furnaces (Muffle, Tube, Rotary, CVD) that are fully customizable for your unique research or production needs.

Ready to achieve superior chemical precision and process efficiency? Contact us today to find your custom solution!

References

- Kilian Sandner, Uwe Glatzel. Investment casting of Cr–Si alloys with liquidus temperatures up to 1900 °C. DOI: 10.1007/s40962-024-01490-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is a quartz tube preferred as the reactor body in induction heating? Maximize Efficiency & Energy Focus

- What are the main components of a Vacuum Induction Melting Furnace? Discover Key Parts for High-Purity Metal Production

- Why is the compact design of channel induction furnaces advantageous? Unlock Space & Energy Savings

- What is the role of a Vacuum-arc melting furnace in the preparation of Ti–Mo–Fe alloys? Essential for High-Purity Synthesis

- Why does the preparation of high-entropy alloys require a vacuum arc furnace? Ensure Homogeneity & Purity.

- What is an induction furnace used to produce? Achieve Clean, Efficient Metal Melting

- What are the key properties of titanium alloys and why are they melted in VIM furnaces? Unlock High-Performance Alloy Production

- What determines the depth of heating in induction processes? Master Frequency & Material Control