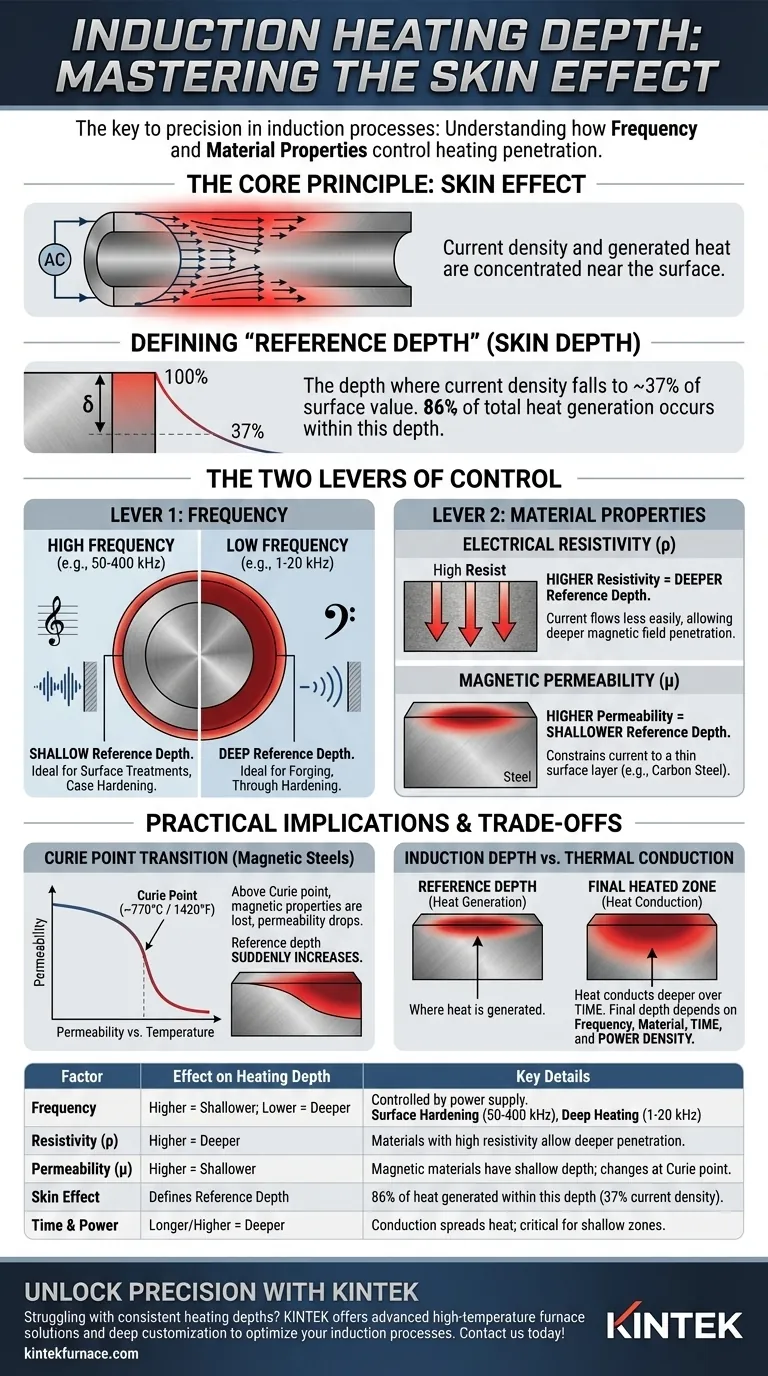

The depth of heating in an induction process is primarily determined by two factors: the frequency of the alternating current from the power supply and the intrinsic electrical and magnetic properties of the material being heated. In short, higher frequencies result in shallower heating, while lower frequencies penetrate deeper into the workpiece.

The core principle you must understand is the "skin effect." Heat is not generated uniformly throughout the part; it is concentrated near the surface. The depth of this heated layer is a predictable and controllable parameter, making induction a highly precise tool when you master the relationship between frequency and material.

The Core Principle: Understanding the Skin Effect

To control heating depth, you must first understand why it occurs. The phenomenon responsible is known as the skin effect, a fundamental principle of electromagnetism.

What is the Skin Effect?

When an alternating current (AC) flows through a conductor, it does not distribute itself evenly across the conductor's cross-section. Instead, the current is densest at the surface and its density decreases exponentially toward the center.

Because resistive heating is directly proportional to the current squared (I²R), the heat is also generated in this thin, current-carrying layer, or "skin."

Defining "Reference Depth"

The "electrical reference depth" (or skin depth) is the standard technical measure for this effect. It is defined as the depth from the surface where the induced current density has fallen to approximately 37% of its value at the surface.

For practical purposes, about 86% of all the heat generated by the induction process occurs within this single reference depth. This makes it the most critical parameter for calculating and controlling your heating results.

The Two Levers of Control

You can control the reference depth by manipulating one key process variable and understanding one set of material properties.

Lever 1: Frequency

Frequency is the most important and most direct control you have over heating depth. It is determined by your induction power supply. The relationship is simple and inverse:

- High Frequency = Shallow Reference Depth

- Low Frequency = Deep Reference Depth

Think of it like sound waves. High-frequency treble is easily blocked by a wall, while low-frequency bass can penetrate through it. Similarly, high-frequency currents cannot penetrate far into a metal, concentrating their energy near the surface.

This allows for precise application-based choices. High frequencies (50 kHz - 400 kHz+) are used for surface treatments like case hardening, while low frequencies (1 kHz - 20 kHz) are used for applications requiring deep heat, such as forging or through hardening.

Lever 2: Material Properties

The specific material of the workpiece also plays a critical, non-negotiable role in determining the reference depth. Two properties are key:

- Electrical Resistivity (ρ): Higher resistivity makes it more difficult for current to flow, which allows the magnetic fields to penetrate deeper. Therefore, higher resistivity leads to a deeper reference depth.

- Magnetic Permeability (μ): This property describes how easily a material can be magnetized. For magnetic materials like carbon steel, high permeability dramatically constrains the current to a very thin layer, resulting in a much shallower reference depth compared to non-magnetic materials like aluminum or copper at the same frequency.

Understanding the Trade-offs and Practical Implications

Knowing the theory is one thing; applying it requires understanding the complexities that arise during the actual heating process.

The Curie Point Transition

For magnetic steels, the most significant practical consideration is the Curie temperature (approximately 770°C or 1420°F). Above this temperature, the steel loses its magnetic properties, and its permeability drops to that of a non-magnetic material.

This means that as a magnetic part heats up, the reference depth will suddenly increase once it passes the Curie point. A process designed for shallow surface heating can quickly become a deep heating process, requiring sophisticated power control to avoid overheating or unintended results.

Induction Depth vs. Thermal Conduction

It is critical to distinguish between the depth where heat is generated (the reference depth) and the final depth of the heated zone. The final depth is also a function of time and power density.

Even with a high frequency creating a shallow reference depth, if you apply power for a long duration, that heat will conduct deeper into the core of the part. To achieve a truly shallow heat-affected zone, you need a high frequency combined with a short, high-power heating cycle.

Matching Frequency to Your Application

Choosing the right parameters is about matching the equipment to the metallurgical goal.

- If your primary focus is surface hardening or case hardening: Use high frequencies (50 kHz to 400 kHz or higher) to concentrate heat precisely on the surface and create a hard outer case while leaving a ductile core.

- If your primary focus is through hardening or pre-heating for forging: Use low to medium frequencies (1 kHz to 20 kHz) to achieve deep, slow, and uniform heating throughout the component's cross-section.

- If your primary focus is melting large billets: Use very low frequencies (50 Hz to 3 kHz) to ensure the magnetic field penetrates fully and the entire mass is heated through to its melting point.

- If you are heating magnetic steel for hardening: Account for the change in heating depth at the Curie point, often requiring a power supply that can adapt its output to maintain consistent heating.

By mastering the relationship between frequency, material, and time, you transform induction heating from a concept into a precise and repeatable manufacturing tool.

Summary Table:

| Factor | Effect on Heating Depth | Key Details |

|---|---|---|

| Frequency | Higher frequency = shallower depth; Lower frequency = deeper depth | Controlled by power supply; used for surface hardening (50-400 kHz) or deep heating (1-20 kHz) |

| Material Resistivity (ρ) | Higher resistivity = deeper depth | Affects current flow; materials with high resistivity allow deeper penetration |

| Material Permeability (μ) | Higher permeability = shallower depth | Magnetic materials (e.g., steel) have shallow depth; changes at Curie point (~770°C) |

| Skin Effect | Defines reference depth where current density drops to 37% | 86% of heat generated within this depth; enables precise control |

| Time and Power Density | Longer time/higher power = deeper heated zone via conduction | Combines with frequency for final depth; critical for shallow heat-affected zones |

Unlock Precision in Your Induction Heating Processes with KINTEK

Are you struggling to achieve consistent heating depths in your induction applications? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to meet the unique requirements of diverse laboratories and industrial settings. With our strong deep customization capability, we can help you optimize frequency and material parameters for superior results in surface hardening, through hardening, or melting processes.

Contact us today to discuss how our expertise can enhance your efficiency and precision — Get in touch now!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What are the main advantages of PECVD tube furnaces compared to CVD tube furnaces? Lower Temp, Faster Deposition, and More

- What are gas barrier films, and how is PECVD involved in their creation? Discover Advanced Packaging Solutions

- What is the difference between PVD and PECVD? Choose the Right Thin-Film Coating Technology

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK

- What are the future trends in CVD technology? AI, Sustainability, and Advanced Materials