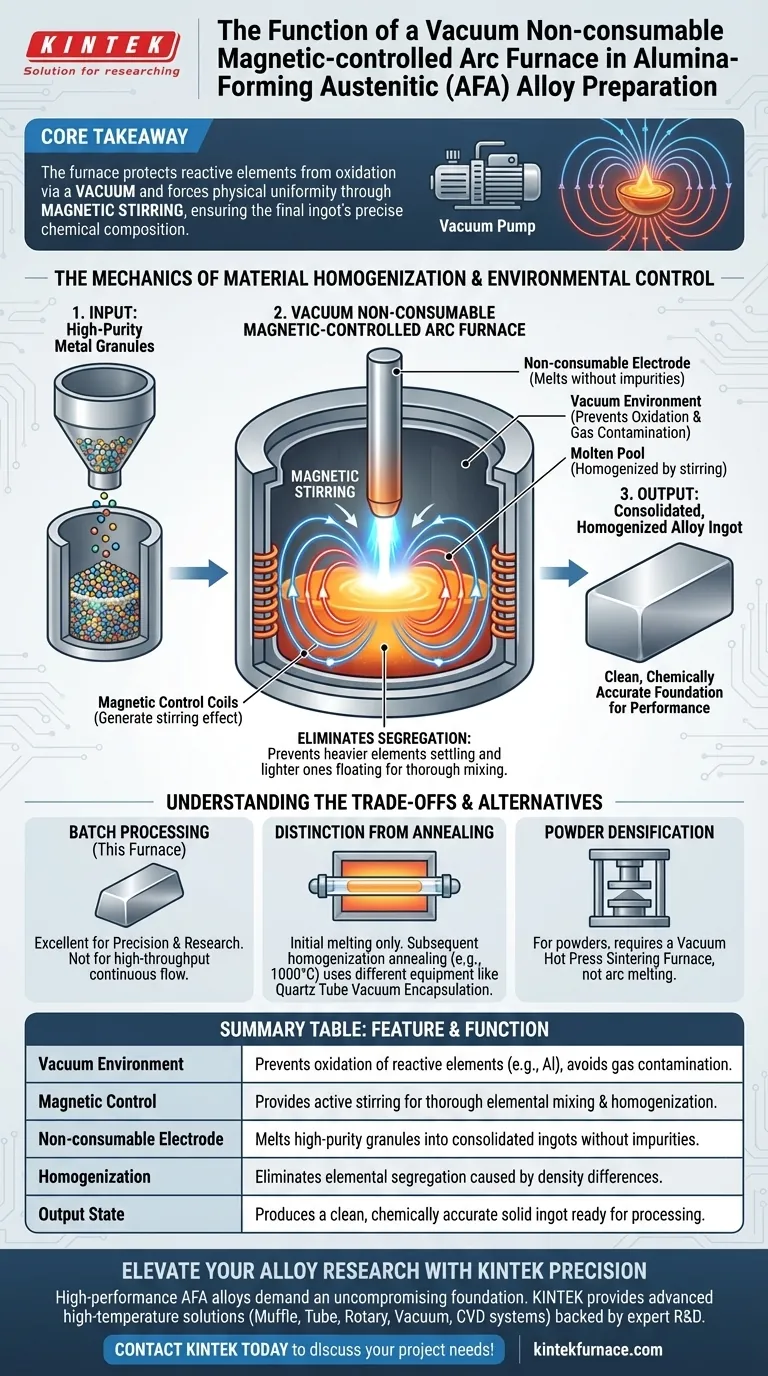

The Vacuum Non-consumable Magnetic-controlled Arc Furnace is the critical equipment used to melt high-purity metal granules into precise alloy ingots during the initial preparation of Alumina-Forming Austenitic (AFA) alloys. By leveraging a vacuum environment and magnetic fields, it transforms raw materials into a homogenized solid state while preventing chemical degradation.

Core Takeaway The furnace serves a dual purpose: it protects reactive elements from oxidation via a vacuum, and it forces physical uniformity through magnetic stirring. This ensures the final ingot matches the intended chemical composition exactly, which is the foundation for all subsequent material performance.

The Mechanics of Material Homogenization

Melting High-Purity Granules

The primary role of this furnace is the transition of raw materials. It takes high-purity metal granules and melts them down into a consolidated alloy ingot.

This is the first and most critical step in establishing the material's structural integrity.

Magnetic Control for Uniformity

AFA alloys often contain elements with varying densities and melting points. The magnetic control technology within the furnace addresses this by generating a stirring effect within the molten pool.

This active stirring ensures that all constituent elements are thoroughly mixed.

Eliminating Segregation

Without this magnetic intervention, heavier elements might settle while lighter ones float. The furnace ensures thorough homogenization, preventing compositional segregation that would weaken the final alloy.

Environmental Control and Purity

Preventing Oxidation

AFA alloys typically contain reactive elements like aluminum. The furnace operates under a vacuum environment, which is essential for excluding oxygen during the high-temperature melting phase.

This prevents the formation of unwanted oxides that can act as defects in the material.

Avoiding Gas Contamination

Beyond oxygen, the vacuum protects the molten pool from nitrogen and hydrogen contamination. Gas contamination can lead to porosity or brittleness.

By isolating the melt, the furnace ensures the accuracy of the final chemical composition.

Understanding the Trade-offs

Batch Processing vs. Continuous Flow

This type of furnace is typically designed for batch processing of ingots. While excellent for precision and research, it may not offer the throughput speed of continuous casting methods used in lower-grade commercial steel production.

Distinction from Annealing

It is vital not to confuse the melting stage with the annealing stage. While this furnace handles the initial melting, subsequent homogenization annealing (often at 1000°C) requires different equipment, such as vacuum encapsulation in quartz tubes.

The furnace creates the ingot; the quartz tube encapsulation maintains stability during long-duration heat treatments.

Making the Right Choice for Your Goal

- If your primary focus is initial alloy creation: Rely on the Vacuum Non-consumable Magnetic-controlled Arc Furnace to turn raw granules into a clean, homogeneous ingot.

- If your primary focus is long-term heat treatment: Move the prepared ingot to a quartz tube vacuum encapsulation setup to prevent oxidation during the days-long annealing process.

- If your primary focus is powder densification: You would require a vacuum hot press sintering furnace, which applies pressure to powders, rather than the arc melting process used here.

The Vacuum Non-consumable Magnetic-controlled Arc Furnace provides the uncontaminated, uniform foundation required for high-performance AFA alloy development.

Summary Table:

| Feature | Function in AFA Alloy Preparation |

|---|---|

| Vacuum Environment | Prevents oxidation of reactive elements like Al and avoids gas contamination. |

| Magnetic Control | Provides active stirring to ensure thorough elemental mixing and homogenization. |

| Non-consumable Electrode | Melts high-purity granules into consolidated ingots without introducing impurities. |

| Homogenization | Eliminates elemental segregation caused by density differences. |

| Output State | Produces a clean, chemically accurate solid ingot ready for further processing. |

Elevate Your Alloy Research with KINTEK Precision

High-performance Alumina-Forming Austenitic (AFA) alloys demand an uncompromising foundation. KINTEK provides the advanced high-temperature solutions you need to ensure material integrity. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab furnaces—all fully customizable to meet your unique metallurgical requirements.

Whether you are melting high-purity granules or performing long-term vacuum annealing, our equipment delivers the precision your lab deserves. Contact KINTEK today to discuss your project needs!

Visual Guide

References

- Qingfeng Jia, Xuping Su. Effect of Si on Mechanical Properties and Oxide Film Formation of AFA Alloy at Low Oxygen Pressure. DOI: 10.3390/coatings15050602

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What industries benefit from induction heat treatment and why? Boost Efficiency and Durability in Metalworking

- In what ways does induction heating promote resource efficiency? Achieve Precision, Speed, and Sustainability

- What makes induction furnaces suitable for precious metals processing? Unlock Purity and Efficiency in Metal Melting

- What are the advantages of using a VIM furnace to control residual oxygen pressure? Achieve Superior Metal Uniformity

- What are the key benefits of using induction furnaces for smelting precious metals? Maximize Purity and Yield

- Why are Water Cooled Copper Pots utilized during the melting process of titanium alloys? Ensure Purity with Skull Melting

- What is the role of vacuum induction furnaces in aluminum alloy oxidation research? Mastering Melt Environment Control

- What is the role of shell mold heating in a vacuum induction furnace? Optimize Casting Flow & Integrity