At its core, induction heat treatment is indispensable for industries that depend on the high-volume production of strong, durable, and wear-resistant metal components. This makes it a cornerstone technology in sectors like automotive manufacturing, construction machinery, and petrochemicals, where the precision, speed, and quality of the heat-treating process directly impact product reliability and performance.

The true value of induction heating lies in its control. By using an electromagnetic field to generate rapid, targeted, and repeatable heat directly within a part, it allows manufacturers to create stronger components with unparalleled consistency and operational efficiency.

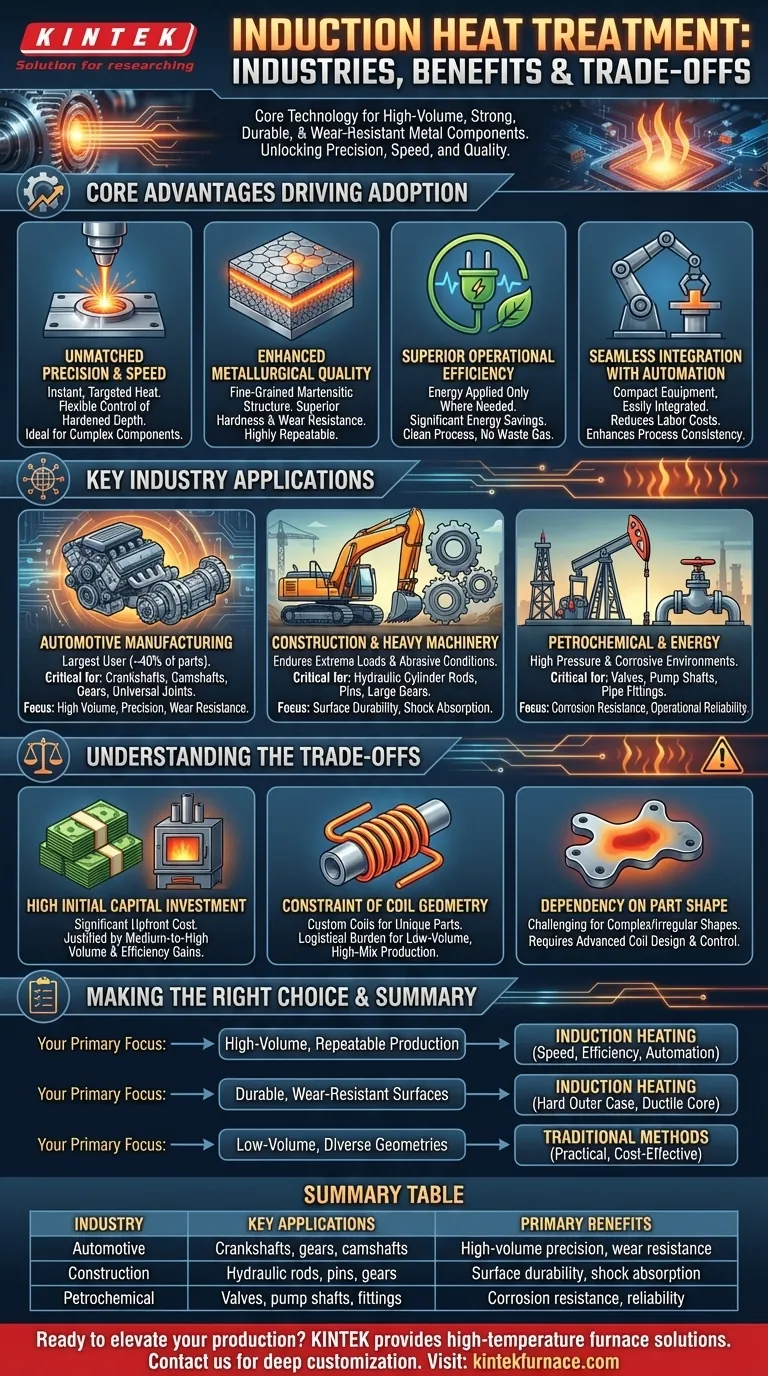

The Core Advantages Driving Adoption

The widespread use of induction heat treatment is not accidental. It is driven by a unique combination of metallurgical and operational benefits that traditional furnace-based methods cannot match.

Unmatched Precision and Speed

Induction heating generates heat inside the workpiece itself through an alternating magnetic field. This process is nearly instantaneous and can be confined to very specific areas of a part.

This allows for precise control over which sections are hardened and to what depth, a level of flexibility crucial for complex components.

Enhanced Metallurgical Quality

The rapid heating and quenching cycles characteristic of induction treatment produce a very fine-grained martensitic microstructure in steel. This results in superior hardness and exceptional wear resistance on the surface.

This is why it is the preferred method for parts like gears, shafts, and bearings, which require a hard, durable surface to handle friction and a softer, more ductile core to absorb shock. The process is highly repeatable, ensuring stable product quality across millions of parts.

Superior Operational Efficiency

Unlike a furnace that must heat the entire chamber, induction heating applies energy only where it is needed. This results in significant energy savings.

Furthermore, because it relies on electricity and not combustion, the process is clean, producing no smoke or waste gas. This drastically improves working conditions and simplifies environmental compliance.

Seamless Integration with Automation

The equipment for induction heating is compact and lends itself perfectly to automation. Induction coils can be easily integrated into production cells and assembly lines, managed by robotics and PLCs.

This not only reduces labor costs but also further enhances process consistency, removing the variables of human operation.

Key Industry Applications

While the principles are universal, certain industries leverage these benefits more than others due to their specific production demands.

Automotive Manufacturing

The automotive industry is the largest user of induction heating. It is estimated that approximately 40% of all automotive parts undergo some form of induction treatment.

Critical components like crankshafts, camshafts, gears, universal joints, and half shafts rely on induction hardening to withstand the immense and continuous stresses of a vehicle's drivetrain and engine. The high volume and strict quality requirements of this sector make induction an ideal fit.

Construction and Heavy Machinery

Components for construction equipment, such as excavators, bulldozers, and cranes, must endure extreme loads and abrasive conditions.

Induction hardening provides the necessary surface durability for parts like hydraulic cylinder rods, pins, and large gears, preventing premature wear and failure in the field.

Petrochemical and Energy

In the petrochemical and energy sectors, components like valves, pump shafts, and pipe fittings must operate reliably under high pressure and in corrosive environments.

Induction heating is used to selectively harden critical surfaces, enhancing their resistance to wear and corrosion without compromising the overall strength and integrity of the part.

Understanding the Trade-offs

Despite its many advantages, induction heating is not a universal solution. It's important to recognize its limitations to make an informed decision.

High Initial Capital Investment

The power supplies, custom-designed induction coils, and automated handling systems represent a significant upfront cost compared to a simple convection furnace.

This investment is typically justified only for medium- to high-volume production runs where the gains in speed and energy efficiency provide a clear return.

The Constraint of Coil Geometry

The induction coil, which creates the magnetic field, must be carefully designed and shaped to match the part's geometry for effective heating.

This means that each unique part often requires its own custom coil. For low-volume, high-mix production environments, this can become a logistical and financial burden.

Dependency on Part Shape

While excellent for cylindrical or relatively uniform parts, achieving even heating on highly complex or irregular shapes can be challenging. Thin sections may overheat while thick sections remain too cool, requiring advanced coil design and process control.

Making the Right Choice for Your Goal

Selecting the correct heat treatment method requires aligning the technology's strengths with your primary objective.

- If your primary focus is high-volume, repeatable production: Induction heating is the superior choice due to its unmatched speed, energy efficiency, and suitability for automation.

- If your primary focus is creating durable, wear-resistant surfaces: This method excels at creating a hard outer case while maintaining a ductile core, making it perfect for parts like gears, shafts, and bearings.

- If your primary focus is low-volume work or treating diverse part geometries: The high initial cost and need for part-specific coils may make traditional furnace-based methods a more practical and cost-effective solution.

By matching the unique benefits of induction heating to your specific production goals, you can unlock significant gains in quality, efficiency, and long-term component reliability.

Summary Table:

| Industry | Key Applications | Primary Benefits |

|---|---|---|

| Automotive | Crankshafts, gears, camshafts | High-volume precision, wear resistance |

| Construction | Hydraulic rods, pins, gears | Surface durability, shock absorption |

| Petrochemical | Valves, pump shafts, fittings | Corrosion resistance, operational reliability |

Ready to elevate your production with advanced heat treatment solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering enhanced efficiency, durability, and cost savings. Contact us today to discuss how we can tailor our solutions for your industry needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability