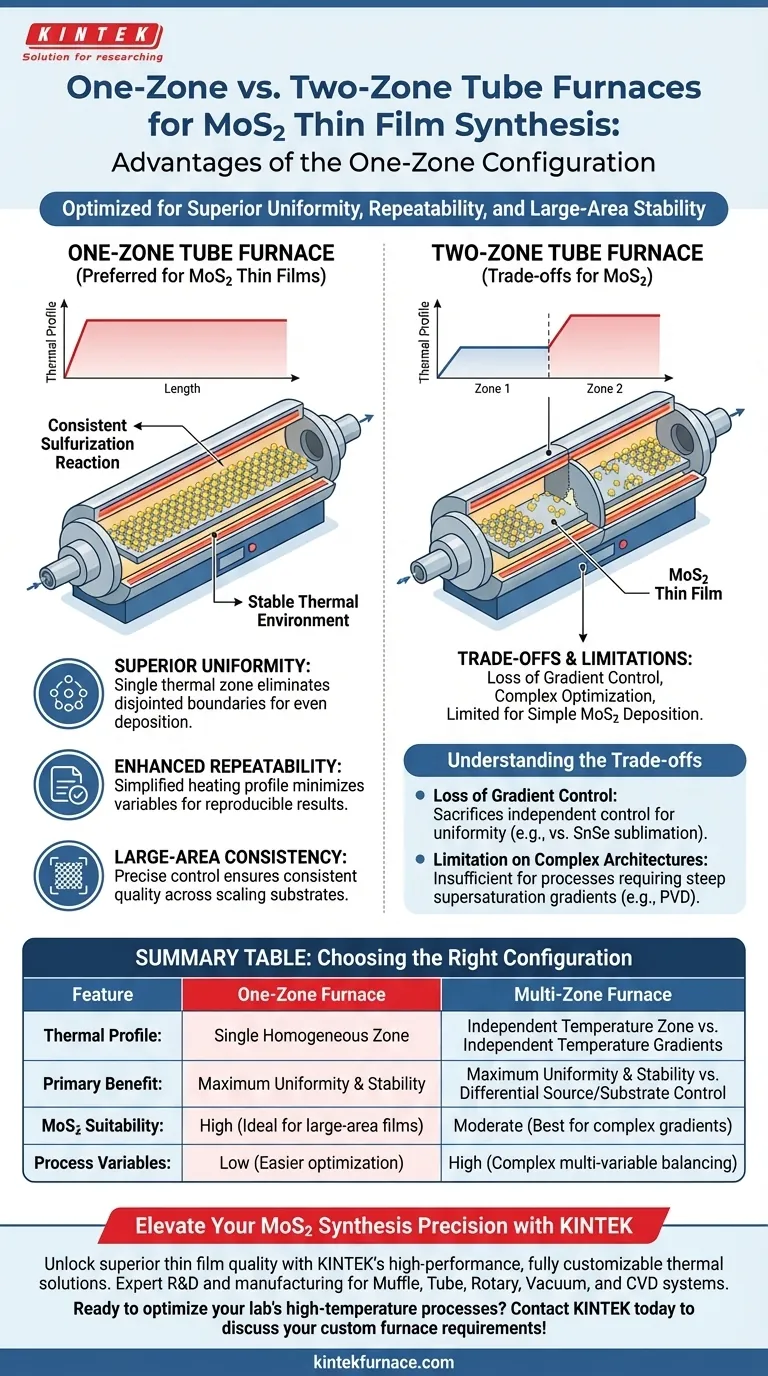

For the synthesis of molybdenum disulfide (MoS2) thin films, the primary advantage of a one-zone tube furnace is its ability to deliver superior uniformity and repeatability. While multi-zone configurations offer gradient control, the one-zone setup creates a more stable thermal environment that is specifically optimized for controlling the stability of the sulfurization reaction across large areas.

Core Takeaway Achieving high-quality MoS2 thin films often relies less on complex temperature gradients and more on reaction stability. A one-zone furnace excels here by eliminating thermal boundaries, ensuring consistent sulfurization and repeatable film quality across the entire substrate.

The Impact on Film Quality

Superior Uniformity

The most critical challenge in thin film synthesis is ensuring the material is deposited evenly. A one-zone furnace maintains a single, homogeneous thermal profile. This eliminates the risk of disjointed thermal zones that can lead to uneven growth rates across the substrate.

Enhanced Repeatability

In experimental and production environments, the ability to reproduce results is paramount. By reducing the complexity of the heating profile, the one-zone configuration minimizes process variables. This ensures that optimized process conditions yield the same high-quality results in subsequent runs.

Large-Area Consistency

When synthesizing films over larger substrates, thermal consistency becomes difficult to maintain. The one-zone configuration allows for precise control over the reaction environment. This ensures consistent results even when scaling up to larger-area thin films.

Process Control and Stability

Stabilizing the Sulfurization Reaction

The chemical reaction between the molybdenum precursor and sulfur is sensitive. The one-zone furnace allows for precise control over the stability of this sulfurization reaction. By keeping the entire reaction chamber at a unified temperature, the process avoids the instability that can occur at the interface of different temperature zones.

Optimization Simplicity

Optimizing a process in a one-zone furnace focuses on a single thermal variable. This allows researchers to fine-tune the environment more effectively than trying to balance the interaction between two or three independent zones.

Understanding the Trade-offs

Loss of Gradient Control

It is important to recognize what you sacrifice when choosing a one-zone setup. As noted in processes for other materials like Tin Selenide (SnSe), multi-zone furnaces (two-zone or three-zone) provide independent control over sublimation and deposition zones.

Limitation on Complex Architectures

If your specific synthesis method requires a steep temperature gradient to regulate supersaturation levels—common in Physical Vapor Deposition (PVD) or bulk crystal growth—a one-zone furnace will be insufficient. The one-zone system is specialized for uniformity, not for separating source and substrate temperatures.

Making the Right Choice for Your Goal

To select the correct furnace configuration, you must prioritize your specific processing needs:

- If your primary focus is MoS2 Thin Film Uniformity: Choose the one-zone furnace to maximize large-area consistency and reaction stability.

- If your primary focus is Complex Crystal Growth (e.g., SnSe): Choose a multi-zone furnace to leverage independent temperature gradients for controlling supersaturation.

By aligning your equipment choice with the specific chemical needs of MoS2, you ensure a robust and repeatable synthesis process.

Summary Table:

| Feature | One-Zone Furnace | Multi-Zone Furnace |

|---|---|---|

| Thermal Profile | Single Homogeneous Zone | Independent Temperature Gradients |

| Primary Benefit | Maximum Uniformity & Stability | Differential Source/Substrate Control |

| MoS2 Suitability | High (Ideal for large-area films) | Moderate (Best for complex gradients) |

| Process Variables | Low (Easier optimization) | High (Complex multi-variable balancing) |

Elevate Your MoS2 Synthesis Precision with KINTEK

Unlock superior thin film quality with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research or production needs. Whether you require the stable uniformity of a one-zone furnace for consistent sulfurization or a complex multi-zone system, our engineering team ensures you have the right tools for breakthrough results.

Ready to optimize your lab's high-temperature processes? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Saiful Islam, Nowshad Amin. Modulating Molybdenum Disulfide (MoS <sub>2</sub> ) Thin Films Formation via Vapor-Phase Synthesis: Time Variation. DOI: 10.1088/1755-1315/1560/1/012038

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How is a laboratory tube furnace utilized to convert metal-organic precursors? Master Thin Film Pyrolysis Today

- What role does a high-temperature tube furnace play in the post-treatment of Ir-TiO2 samples? Master Material Purity

- What is the specific role of a Tube Furnace in the synthesis of sodium cobalt borate (NCBO)? Achieve Pure Crystals

- Why is a High Vacuum or High Purity Nitrogen Tube Furnace necessary for the growth of carbide precipitates in steel?

- What are some common applications of tube furnaces? Unlock Precision in High-Temperature Processes

- What is the primary function of a high-temperature tube furnace in Bi-doped CaZnOS synthesis? Achieving Phase Purity

- How does a tube furnace facilitate the synthesis of layered oxide materials for sodium-ion batteries? Precision Growth

- How does a vacuum tube furnace contribute to product sintering? Achieve Pure, High-Density Materials