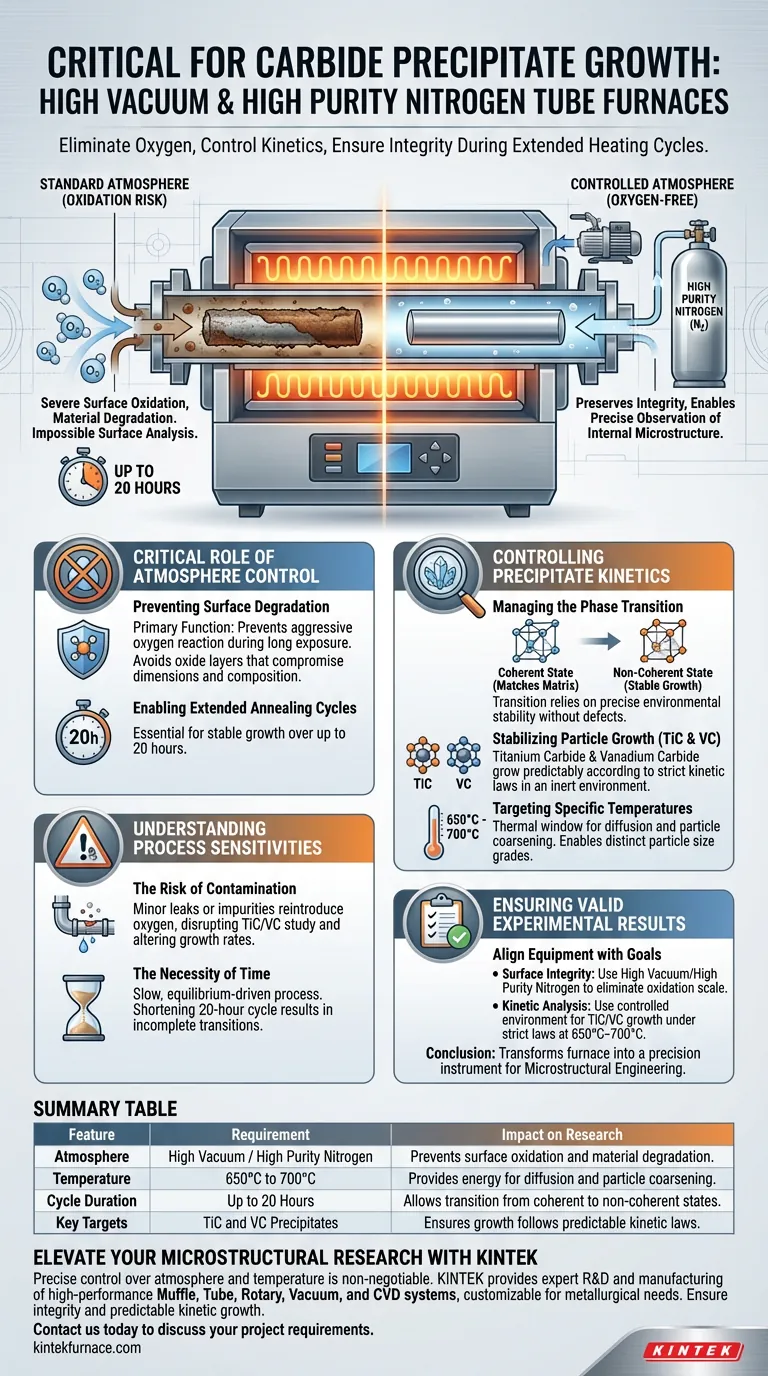

The necessity of a High Vacuum or High Purity Nitrogen Tube Furnace lies in its ability to eliminate oxygen during the extended heating cycles required for steel alloy research. When annealing alloys for durations up to 20 hours, standard atmospheric conditions would cause immediate and severe surface oxidation. By maintaining an extremely low oxygen environment, these furnaces preserve the integrity of the sample, allowing for the precise observation of internal microstructural changes without external interference.

Core Takeaway To successfully transition precipitates from coherent to non-coherent states, you must isolate the material from environmental contaminants. A high vacuum or high-purity nitrogen atmosphere is the only way to ensure that particle growth is driven solely by kinetic laws and temperature, rather than by surface degradation or oxidation.

The Critical Role of Atmosphere Control

Preventing Surface Degradation

The primary function of using High Vacuum or High Purity Nitrogen is to prevent surface oxidation.

When steel alloys are exposed to high temperatures for long periods, oxygen reacts aggressively with the metal surface.

This reaction creates oxide layers that can compromise the material's dimensions and chemical composition, rendering surface analysis impossible.

Enabling Extended Annealing Cycles

The growth of carbide precipitates is not an instantaneous process; it requires significant time.

Specific annealing protocols often demand durations of up to 20 hours.

Maintaining a pure, oxygen-free environment for this length of time is essential to ensure the material remains stable throughout the entire treatment.

Controlling Precipitate Kinetics

Managing the Phase Transition

The goal of this specific heat treatment is to control the transition of precipitates.

You are moving particles from a coherent state (where their crystal lattice matches the metal matrix) to a non-coherent state.

This delicate transition relies on precise environmental stability to proceed without defects.

Stabilizing Particle Growth

The furnace allows for the stable growth of specific carbide particles, specifically Titanium Carbide (TiC) and Vanadium Carbide (VC).

These particles grow according to strict kinetic laws.

An inert or vacuum environment ensures that this growth is predictable and repeatable.

Targeting Specific Temperatures

To facilitate this growth, the furnace must maintain a temperature range between 650°C and 700°C.

This thermal window provides the necessary energy for diffusion and particle coarsening.

Precise temperature control, combined with atmosphere control, enables the production of distinct particle size grades for comparative analysis.

Understanding the Process Sensitivities

The Risk of Contamination

While these furnaces are powerful, the process is highly sensitive to the purity of the environment.

Even a minor leak in a vacuum system or impurities in the nitrogen supply can reintroduce oxygen.

This would immediately disrupt the study of TiC or VC particles, potentially altering their growth rates or surface characteristics.

The Necessity of Time

It is important to recognize that this is a slow, equilibrium-driven process.

Shortening the 20-hour cycle to save time will likely result in incomplete phase transitions.

You must be prepared to commit to the full duration to achieve a true non-coherent state in the precipitates.

Ensuring Valid Experimental Results

If you are aiming to produce reliable data on precipitate growth, you must align your equipment choice with your specific analytical goals.

- If your primary focus is Surface Integrity: You must use High Vacuum or High Purity Nitrogen to completely eliminate the risk of oxidation scale forming during long heat treatments.

- If your primary focus is Kinetic Analysis: You need the controlled environment to ensure TiC and VC particles grow strictly according to kinetic laws at 650°C–700°C without external chemical interference.

By eliminating oxygen and precisely controlling temperature over extended periods, you transform your furnace from a simple heater into a precision instrument for microstructural engineering.

Summary Table:

| Feature | Requirement | Impact on Research |

|---|---|---|

| Atmosphere | High Vacuum / High Purity Nitrogen | Prevents surface oxidation and material degradation. |

| Temperature | 650°C to 700°C | Provides energy for diffusion and particle coarsening. |

| Cycle Duration | Up to 20 Hours | Allows transition from coherent to non-coherent states. |

| Key Targets | TiC and VC Precipitates | Ensures growth follows predictable kinetic laws. |

Elevate Your Microstructural Research with KINTEK

Precise control over atmosphere and temperature is non-negotiable for the growth of carbide precipitates. KINTEK provides expert R&D and manufacturing of high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique metallurgical research needs.

Ensure the integrity of your steel alloys and achieve predictable kinetic growth with our industry-leading high-temperature furnaces. Contact us today to discuss your project requirements and see how our tailored heating solutions can enhance your lab's efficiency.

Visual Guide

References

- Tim Boot, Vera Popovich. Hydrogen trapping and embrittlement of titanium- and vanadium carbide-containing steels after high-temperature hydrogen charging. DOI: 10.1007/s10853-024-09611-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What role does a dual-zone tube furnace play in the synthesis of large-scale Janus RhSeCl single crystals?

- What are the typical applications of tube furnaces? Unlock Precise Thermal Processing for Your Lab

- What is the three-step heating process in graphite furnace atomization? Master Precise Trace Metal Analysis

- What role does a single-zone tube furnace play in synthesizing ZnPS3? Master the Thermal Profile for Layered Materials

- What materials are used for the tubes in a High Temperature Tube Furnace? Choose the Right Tube for Your Lab

- At what pressures can gases be introduced into the 3-Zone tube furnace? Optimize Your Thermal Process Control

- What are the technical advantages of using a tube furnace for rice husk carbonization? Master Precise Synthesis

- Why are tubular furnaces important in material testing and research? Unlock Precision for Advanced Materials Development