In the simplest terms, tubular furnaces are vital to material testing and research because they create a highly uniform and precisely controlled high-temperature environment. This allows scientists to reliably synthesize new materials and test how existing ones behave under extreme conditions, which is fundamental to innovation in fields from aerospace to electronics.

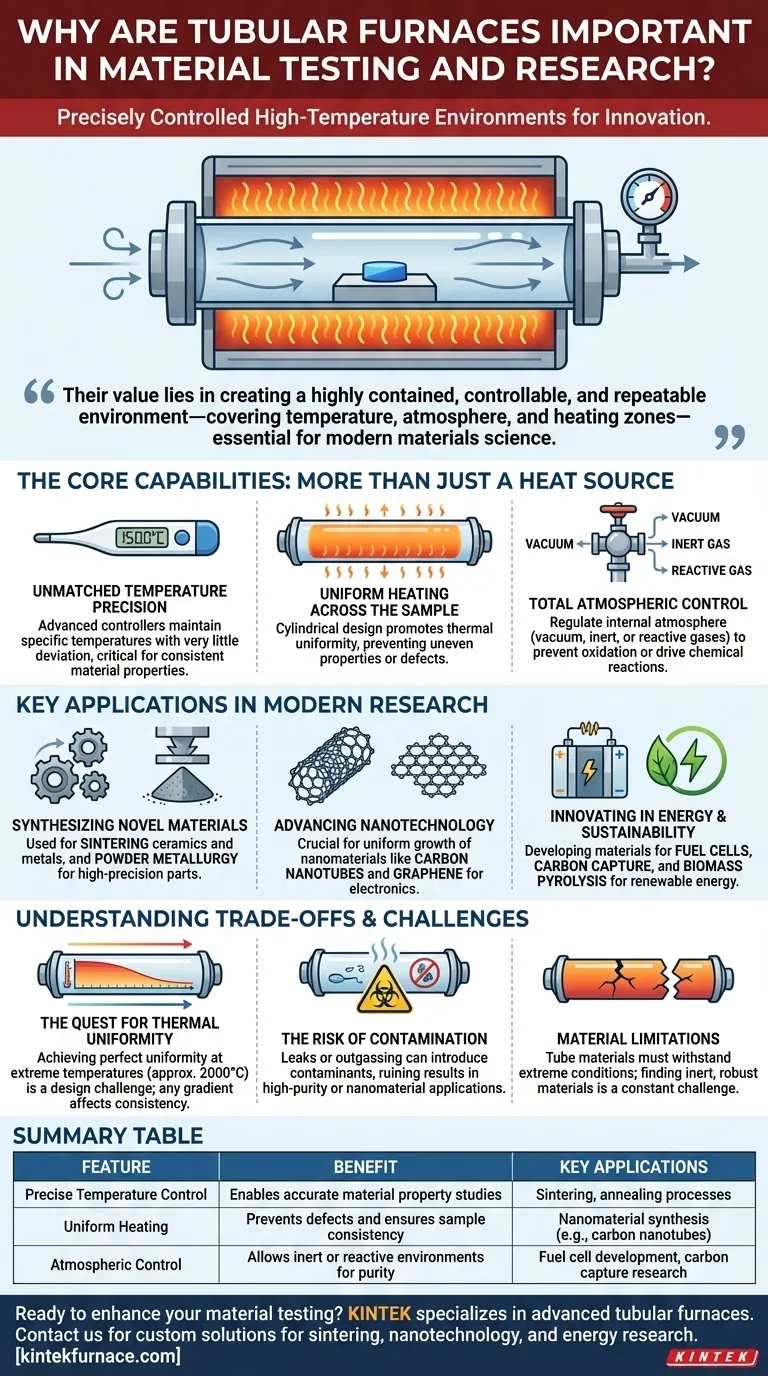

The true importance of a tubular furnace isn't just its ability to generate heat. Its value lies in creating a highly contained, controllable, and repeatable environment—covering temperature, atmosphere, and heating zones—that is essential for modern materials science.

The Core Capabilities: More Than Just a Heat Source

A tubular furnace's design provides a unique combination of features that standard ovens or furnaces cannot match. These capabilities are the reason it has become an indispensable tool in the laboratory.

Unmatched Temperature Precision

Modern tubular furnaces use advanced controllers to maintain a specific temperature with very little deviation. This precision is critical for processes where a few degrees can drastically alter a material's final properties, structure, or performance.

Uniform Heating Across the Sample

The cylindrical design of the heating chamber promotes thermal uniformity. This ensures that the entire sample is exposed to the same temperature, preventing uneven properties or defects that can arise from hot or cold spots.

Total Atmospheric Control

Perhaps its most powerful feature is the ability to regulate the internal atmosphere. By creating a vacuum or introducing specific inert or reactive gases, researchers can prevent oxidation and contamination or actively drive desired chemical reactions. This is crucial for working with sensitive materials.

Key Applications in Modern Research

The precise environmental control offered by tubular furnaces enables a wide range of cutting-edge research and industrial processes.

Synthesizing Novel Materials

These furnaces are used for sintering ceramics and metals, a process that compacts and forms a solid mass of material by heat without melting it to the point of liquefaction. They are also central to powder metallurgy for creating high-precision parts.

Advancing Nanotechnology

The preparation of nanomaterials like carbon nanotubes and graphene relies on the furnace's ability to manage temperature gradients and maintain a pure environment. This control ensures uniform growth and the desired morphology for applications in electronics and energy.

Innovating in Energy and Sustainability

Tubular furnaces are instrumental in developing next-generation materials for fuel cells and researching carbon capture technologies. They are also used for biomass pyrolysis, a process that decomposes organic matter at high temperatures to produce renewable energy.

Understanding the Trade-offs and Challenges

While incredibly powerful, tubular furnaces are not without their operational challenges. Understanding these limitations is key to achieving reliable and meaningful results.

The Quest for Thermal Uniformity

While the design promotes uniformity, achieving it perfectly, especially in longer tubes or at extreme temperatures (approaching 2000°C), remains a design challenge. Any thermal gradient can affect the consistency of the processed material.

The Risk of Contamination

The integrity of the experiment depends on a pure environment. Any leaks, outgassing from the furnace components, or interactions between the sample and the tube material can introduce contaminants that ruin the results, especially in high-vacuum or nanomaterial applications.

Material Limitations

The furnace tube itself must withstand the extreme temperatures and chemical atmospheres used in processing. Finding materials that are both inert and robust at very high temperatures is a constant area of development for furnace manufacturers.

Making the Right Choice for Your Goal

The versatility of a tubular furnace means its setup and use should be directly aligned with your research objective.

- If your primary focus is high-purity material synthesis: Prioritize a system with high-vacuum capabilities and ensure the tube material is inert to your sample.

- If your primary focus is creating bulk components: Concentrate on achieving excellent thermal uniformity for consistent sintering or annealing.

- If your primary focus is exploring fundamental properties: Leverage the furnace's precise temperature and atmospheric controls to isolate variables and study their effects.

Ultimately, the tubular furnace empowers researchers to move beyond theoretical models and physically create the materials of the future.

Summary Table:

| Feature | Benefit | Key Applications |

|---|---|---|

| Precise Temperature Control | Enables accurate material property studies | Sintering, annealing processes |

| Uniform Heating | Prevents defects and ensures sample consistency | Nanomaterial synthesis (e.g., carbon nanotubes) |

| Atmospheric Control | Allows inert or reactive environments for purity | Fuel cell development, carbon capture research |

Ready to enhance your material testing with precise high-temperature solutions? KINTEK specializes in advanced tubular furnaces and custom systems tailored for your lab's unique needs. Our expertise in R&D and in-house manufacturing ensures reliable performance for applications like sintering, nanotechnology, and energy research. Contact us today to discuss how we can support your innovative projects!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability