In short, Microwave Plasma Chemical Vapor Deposition (MPCVD) creates diamond coatings that dramatically increase the hardness, wear resistance, and lifespan of cutting tools. This process allows tools to maintain a sharper edge for longer, leading to significant gains in manufacturing efficiency, precision, and cost savings by reducing tool replacement and machine downtime.

The crucial advantage of MPCVD isn't just that it applies a diamond coating, but how it does so. The method's inherent purity, stability, and control produce a higher-quality diamond film, which directly translates into superior and more reliable real-world performance for the cutting tool.

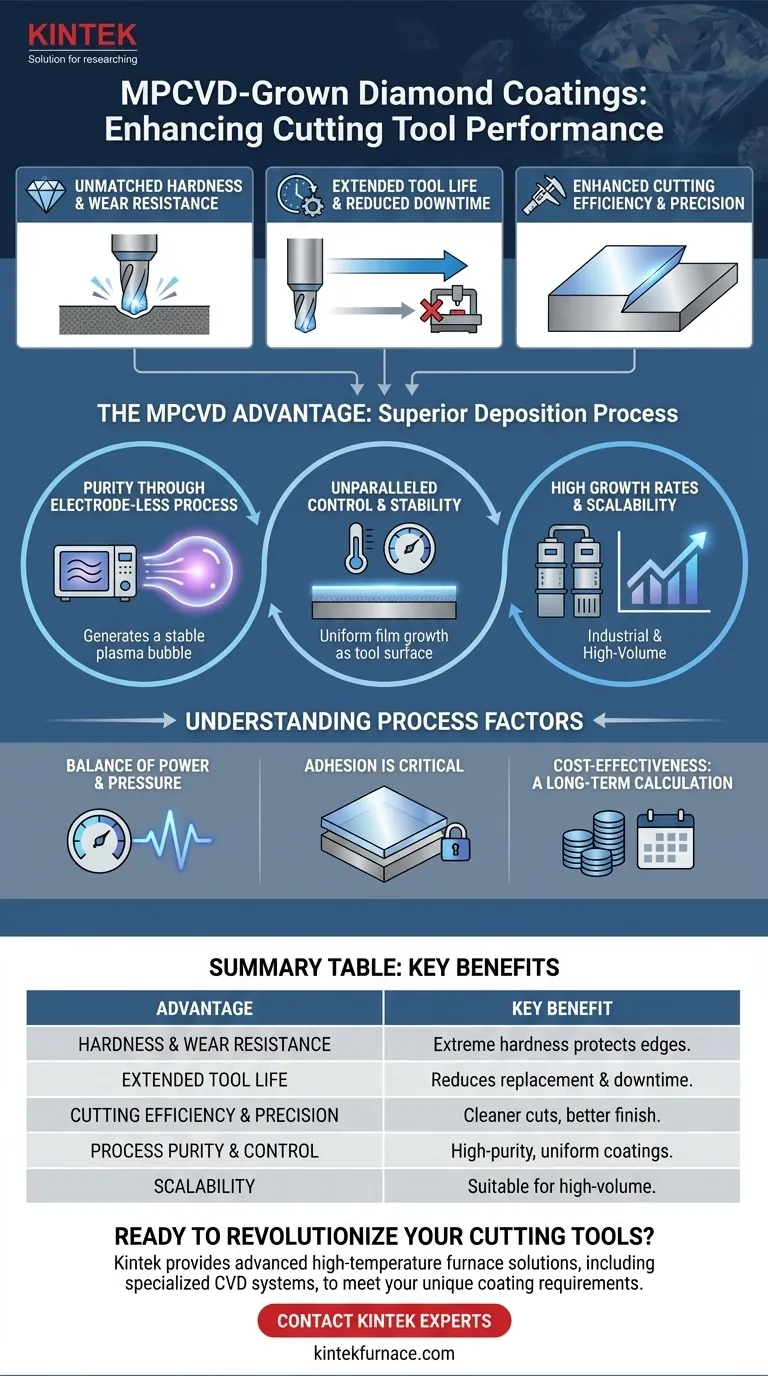

The Core Performance Gains for Cutting Tools

Applying an MPCVD diamond coating fundamentally upgrades the base material of a tool, yielding measurable improvements in key operational areas.

Unmatched Hardness and Wear Resistance

Diamond is the hardest known material. By coating a cutting tool, you transfer this property to its cutting edge.

This extreme hardness provides exceptional resistance to the abrasive wear and friction that occurs during high-speed machining, protecting the underlying tool material from degradation.

Extended Tool Life and Reduced Downtime

Because the cutting edge remains sharp and intact for a much longer period, the tool's service life is significantly extended.

This directly reduces operational costs by minimizing the frequency of tool replacements. More importantly, it cuts down on costly machine downtime required for tool changes, boosting overall production throughput.

Enhanced Cutting Efficiency and Precision

A tool that stays sharp produces cleaner, more precise cuts.

This improves the surface finish of the machined part, potentially reducing the need for secondary finishing operations. The consistent sharpness ensures repeatable quality from the first cut to the last.

Why MPCVD is the Superior Deposition Method

Multiple methods can deposit diamond, but MPCVD offers distinct process advantages that result in a better final product. The quality of the coating is directly tied to the quality of the process used to create it.

Purity Through an Electrode-less Process

Unlike other methods that use hot filaments or electrodes inside the chamber, MPCVD uses microwaves to generate plasma.

This electrode-less process is critical because it eliminates a primary source of contamination. The resulting diamond film is purer, with a better crystal structure, enhancing its hardness and thermal conductivity.

Unparalleled Control and Stability

MPCVD allows for extremely precise and stable control over critical growth parameters like temperature and gas composition.

The plasma it generates is large and highly stable, ensuring uniform deposition across the entire tool surface. This stability allows for continuous, long-duration runs that produce highly reproducible and consistent film quality from batch to batch.

High Growth Rates and Scalability

The MPCVD process can achieve high growth rates, with some systems reaching up to 150 μm/h by optimizing microwave power and chamber pressure.

Furthermore, its modular design is scalable for industrial applications, making it suitable for coating larger substrates and handling the high-volume demands of modern manufacturing.

Understanding the Trade-offs and Process Factors

While highly effective, achieving optimal results with MPCVD requires mastering the process and understanding its context. It is not a universally simple solution.

The Balance of Power and Pressure

The growth rate and film quality are directly influenced by microwave power and gas pressure.

Increasing these parameters can accelerate growth but requires careful optimization. A process that is too aggressive can negatively impact the diamond's crystalline quality or its adhesion to the tool. Expertise is required to balance speed with quality.

Adhesion is as Critical as Hardness

The most perfect diamond film is useless if it delaminates from the tool substrate.

Proper substrate preparation and the potential use of intermediate bonding layers are critical process steps that are just as important as the diamond deposition itself. Achieving strong adhesion is a key challenge in any advanced coating technology.

Cost-Effectiveness is a Long-Term Calculation

MPCVD is noted as cost-effective, but this is relative to other advanced CVD techniques and is based on long-term value.

The initial capital investment in MPCVD equipment can be significant. The return on investment is realized through reduced operational costs—fewer tool purchases, less downtime, and higher productivity—over the equipment's lifespan.

Making the Right Choice for Your Application

Selecting MPCVD is a strategic decision based on your primary manufacturing goals.

- If your primary focus is maximum performance and tool life: MPCVD is the clear choice, as its ability to produce pure, dense diamond films delivers the best possible wear resistance.

- If your primary focus is high-volume, consistent production: The stability, reproducibility, and scalability of MPCVD make it the most reliable method for industrial-level manufacturing.

- If your primary focus is machining non-ferrous materials: Diamond-coated tools excel in cutting composites, graphite, aluminum alloys, and other abrasive non-ferrous materials where tool wear is a major problem.

Ultimately, adopting MPCVD is an investment in achieving a higher threshold of manufacturing efficiency and part quality.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Hardness & Wear Resistance | Extreme hardness protects cutting edges from abrasive degradation. |

| Extended Tool Life | Significantly reduces tool replacement frequency and machine downtime. |

| Cutting Efficiency & Precision | Produces cleaner cuts and better surface finish for repeatable quality. |

| Process Purity & Control | Electrode-less MPCVD ensures high-purity, uniform, and reproducible coatings. |

| Scalability | Suitable for high-volume industrial applications with high growth rates. |

Ready to Revolutionize Your Cutting Tools with MPCVD Diamond Coatings?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and manufacturing facilities with advanced high-temperature furnace solutions. Our product line, including specialized CVD systems, is complemented by our strong deep customization capability to precisely meet your unique coating requirements.

Upgrade your manufacturing process today. Contact our experts to discuss how our MPCVD solutions can deliver superior tool performance and cost savings for your operation.

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance