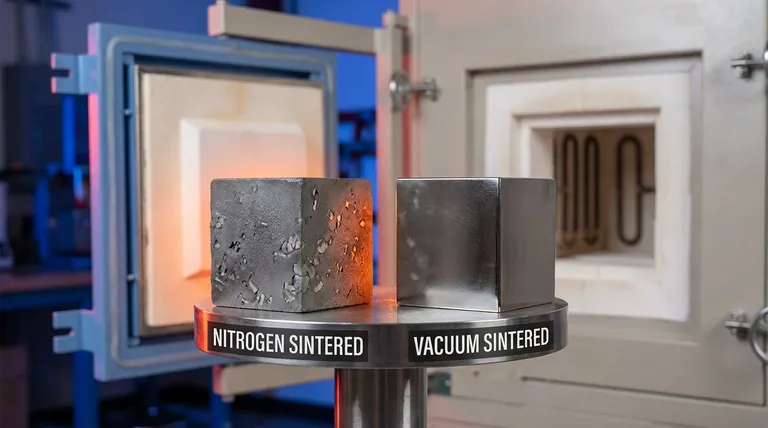

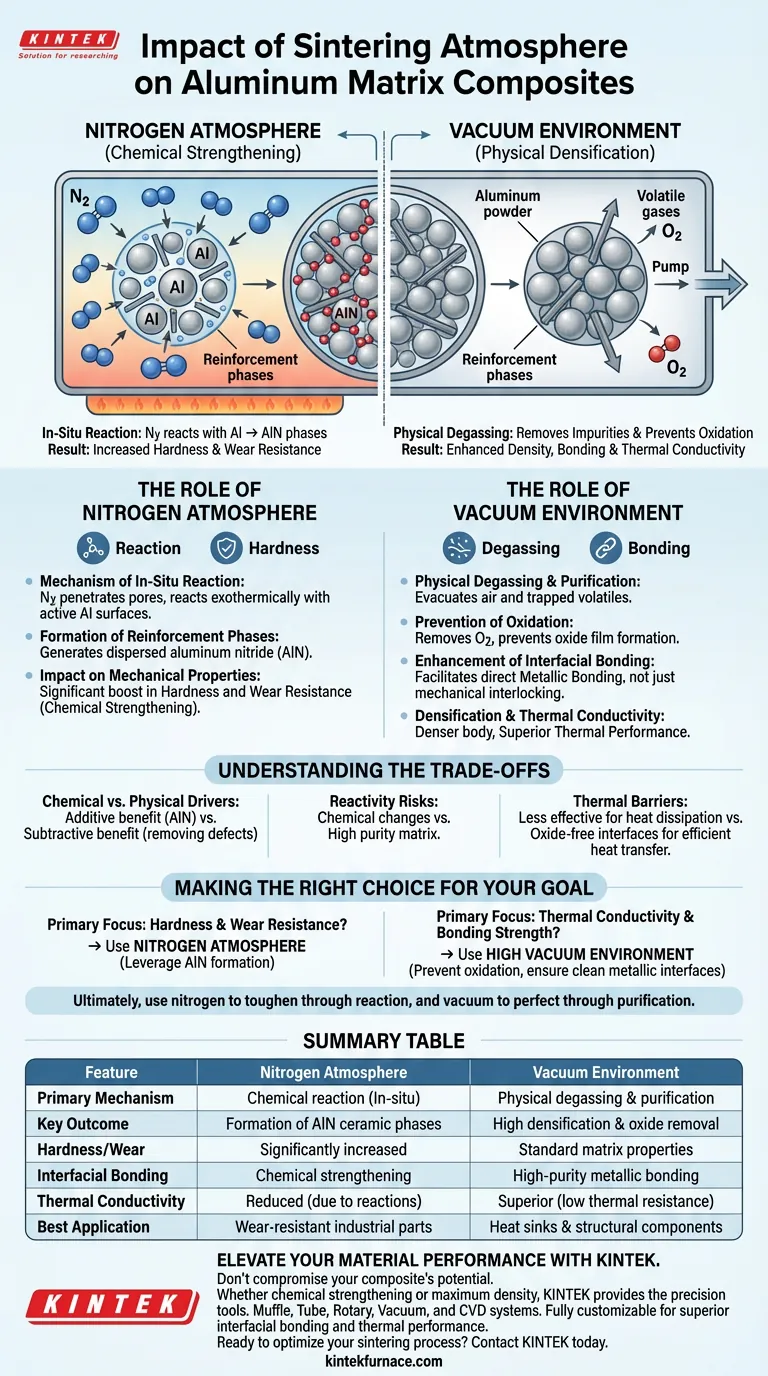

The choice of sintering atmosphere fundamentally dictates whether your composite relies on chemical strengthening or physical densification. In a nitrogen atmosphere, the gas reacts with the aluminum to form hard ceramic phases that significantly boost wear resistance. Conversely, a vacuum environment focuses on removing impurities and preventing oxidation to maximize density, interfacial bonding, and thermal conductivity.

The core distinction lies in the mechanism of property improvement: nitrogen atmospheres actively modify the material's chemistry to create harder parts via aluminum nitride formation, while vacuum environments preserve the matrix's purity to ensure superior structural integrity and thermal performance.

The Role of Nitrogen Atmosphere

Mechanism of In-Situ Reaction

In a nitrogen-rich environment, the gas does not merely act as a protective blanket; it is an active participant. Nitrogen gas penetrates the open pores of the powder compact during the heating phase.

Formation of Reinforcement Phases

Once inside the pores, the nitrogen reacts exothermically with exposed, active aluminum surfaces. This chemical reaction generates dispersed aluminum nitride (AlN) phases within the matrix.

Impact on Mechanical Properties

This process is a form of chemical strengthening. The presence of hard AlN reinforcements significantly improves the hardness and wear resistance of the final part compared to composites sintered in non-reactive environments.

The Role of Vacuum Environment

Physical Degassing and Purification

A vacuum atmosphere functions primarily through physical purification rather than chemical addition. It effectively evacuates air and volatiles trapped in the interstitial spaces between powder particles.

Prevention of Oxidation

High vacuum levels (e.g., $10^{-5}$ mbar) are critical for aluminum, which naturally forms a stubborn oxide film. By removing oxygen and adsorbed gases, the vacuum prevents further oxidation of the aluminum matrix at high temperatures.

Enhancement of Interfacial Bonding

By stripping away volatiles and preventing oxide layers, the vacuum facilitates direct metallic bonding between particles. This "clean" interface is essential for shifting from simple mechanical interlocking to strong metallurgical bonding.

Densification and Thermal Conductivity

The removal of porosity defects leads to a denser sintered body. Furthermore, because oxide films act as thermal barriers, preventing their formation significantly enhances the thermal conductivity of the composite, particularly in applications like diamond-aluminum heat sinks.

Understanding the Trade-offs

Chemical vs. Physical Drivers

You must choose between chemical reaction and physical purity. Nitrogen provides an "additive" benefit by creating new reinforcement phases (AlN), while vacuum provides a "subtractive" benefit by removing defects and oxides.

Reactivity Risks

While nitrogen improves hardness, it introduces chemical changes that may not be desired for all applications. Vacuum sintering avoids these reactions, making it the superior choice when the purity of the matrix and the reinforcement interface is paramount.

Thermal Barriers

If your goal is heat dissipation, nitrogen sintering may be less effective than vacuum. The vacuum process ensures the high-quality, oxide-free interfaces necessary for efficient heat transfer between the matrix and reinforcements.

Making the Right Choice for Your Goal

Select your furnace atmosphere based on the specific performance metric that dictates the success of your component.

- If your primary focus is Hardness and Wear Resistance: Utilize a nitrogen atmosphere to leverage the exothermic formation of aluminum nitride (AlN) for chemically strengthened, durable surfaces.

- If your primary focus is Thermal Conductivity and Bonding Strength: Utilize a high vacuum environment to prevent oxidation, eliminate porosity, and ensure clean metallic interfaces for maximum heat transfer.

Ultimately, use nitrogen when you need to toughen the material through reaction, and use vacuum when you need to perfect the material through purification.

Summary Table:

| Feature | Nitrogen Atmosphere | Vacuum Environment |

|---|---|---|

| Primary Mechanism | Chemical reaction (In-situ) | Physical degassing & purification |

| Key Outcome | Formation of AlN ceramic phases | High densification & oxide removal |

| Hardness/Wear | Significantly increased | Standard matrix properties |

| Interfacial Bonding | Chemical strengthening | High-purity metallic bonding |

| Thermal Conductivity | Reduced (due to reactions) | Superior (low thermal resistance) |

| Best Application | Wear-resistant industrial parts | Heat sinks & structural components |

Elevate Your Material Performance with KINTEK

Don't let the wrong atmosphere compromise your composite's potential. Whether you need to leverage chemical strengthening in a nitrogen environment or achieve maximum density through high-vacuum purification, KINTEK provides the precision tools you need.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temp furnaces are fully customizable to meet the unique requirements of your aluminum matrix projects, ensuring superior interfacial bonding and thermal performance every time.

Ready to optimize your sintering process? Contact KINTEK today to consult with our specialists and find the perfect furnace solution for your lab.

Visual Guide

References

- A Wasik, M. Madej. Sustainability in the Manufacturing of Eco-Friendly Aluminum Matrix Composite Materials. DOI: 10.3390/su16020903

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does a controlled atmosphere furnace improve product quality and consistency? Master Precise Heat Treatment for Superior Results

- What is reducing atmosphere heat treatment? Leverage Precise Chemistry for Pristine Metal Surfaces

- What are some specific applications of retort furnaces? Essential for High-Purity Heat Treatment

- What are the advantages of retort? Unlock Superior Quality with Sealed Processing

- What types of gases can a controlled atmosphere furnace handle? Master Inert and Reactive Gases for Your Lab

- How is the atmosphere controlled in an atmosphere protection muffle furnace? Master Precise Gas Control for Superior Results

- How does an industrial box resistance furnace activate TiO2/ZSM-5 catalysts? Expert Calcination Insights

- How does an argon protection system contribute to composition control of CrMnFeCoNi? Ensure High-Entropy Alloy Purity