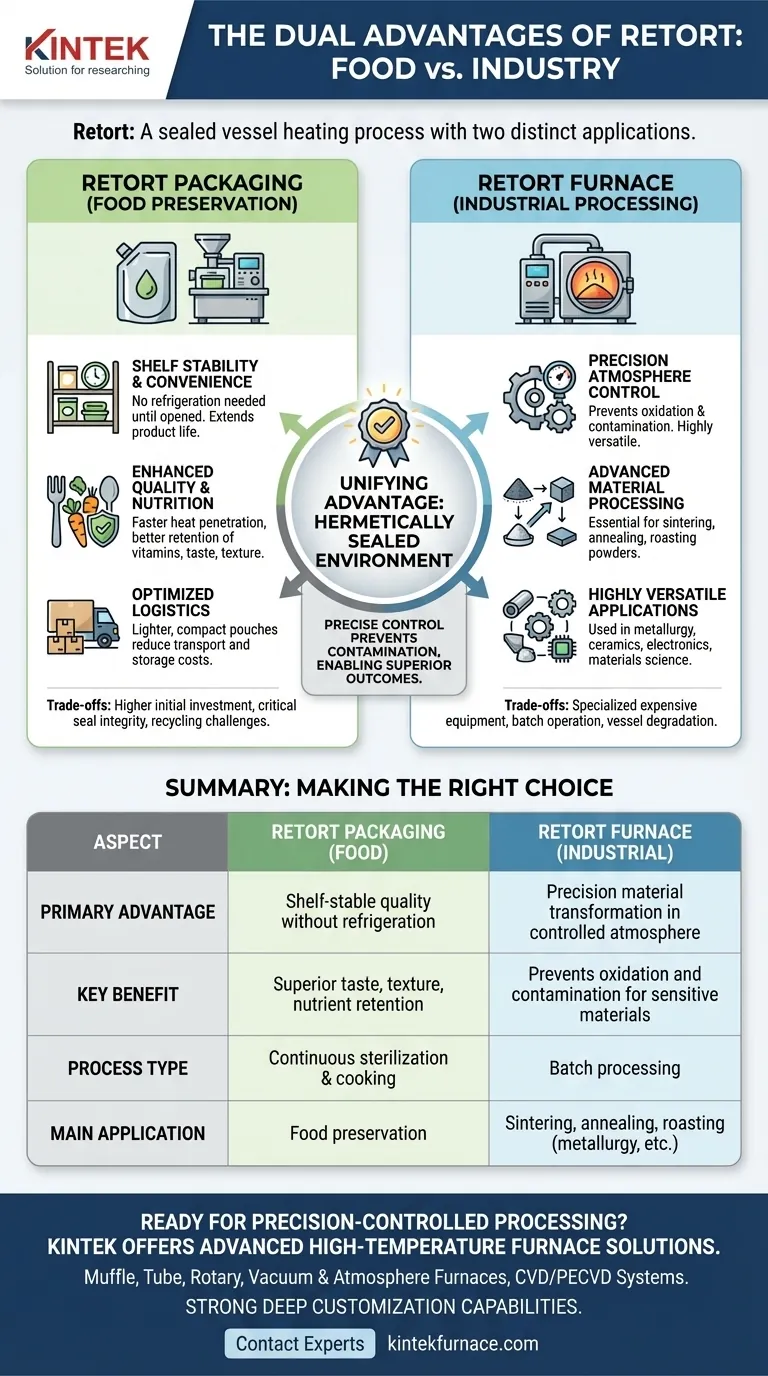

At its core, the term "retort" refers to a process of heating substances in a sealed vessel. This single concept is applied in two vastly different fields, leading to confusion. The primary advantages depend entirely on whether you are referring to retort packaging for food preservation or a retort furnace for industrial material processing. For food, the benefit is shelf-stable quality; for industry, it's precision material transformation.

The unifying advantage of any retort process is the use of a hermetically sealed environment. This precise control prevents contamination and enables outcomes—whether superior food quality or specific material properties—that are impossible in an open system.

The Advantages of Retort Packaging for Food

The most common use of the term "retort" is in food science. It describes a process where food is sealed in a pouch or container and then heated to commercial sterility, combining cooking and sterilization into one step.

Achieving Shelf Stability Without Refrigeration

The process sterilizes the food after it is sealed, killing microorganisms. This gives the product a shelf life similar to traditional canned goods.

Because the food is sterile and sealed, it requires no refrigeration until opened, drastically simplifying the supply chain.

Enhancing Food Quality and Nutrition

Compared to traditional canning, modern retort pouches are thinner and allow for faster, more even heat penetration.

This shorter heating and cooling cycle results in better retention of vitamins, minerals, and nutrients.

It also leads to a superior product taste, texture, and appearance, as the food is not overcooked to the same degree as in a thick metal can.

Optimizing Logistics and Storage

Flexible retort pouches are significantly lighter and more compact than rigid metal cans or glass jars.

This leads to substantial transportation and storage cost savings throughout the entire supply chain.

The empty pouches also require far less space before filling, and the waste material is more compact after the product is consumed.

The Advantages of Retort Furnaces for Industry

In an industrial context, a retort is a vessel inside a furnace that can be sealed off from the outside atmosphere. This allows for high-temperature processing under tightly controlled conditions.

Precision Control Over Atmosphere and Temperature

The sealed design of a retort furnace is its chief advantage. It allows operators to create a specific internal atmosphere, such as a vacuum or an inert gas environment.

This prevents oxidation and contamination from the ambient air, which is critical for processing sensitive materials.

The precise control over both temperature and atmosphere makes these furnaces highly versatile for a wide range of applications.

Enabling Advanced Material Processing

This level of control is essential in metallurgy, ceramics, electronics, and materials science.

It is used for processes like sintering (fusing powders into a solid mass), annealing (altering a material's microstructure to make it more workable), and roasting powders to achieve specific chemical changes.

Without a retort furnace, manufacturing many advanced materials and components would be impossible.

Understanding the Trade-offs

While powerful, retort processes come with specific considerations. Objectively evaluating these trade-offs is key to making an informed decision.

For Retort Packaging

The initial capital investment for retort packaging lines can be higher than for traditional canning or freezing lines.

Seal integrity is absolutely critical. Any failure in the pouch's seal compromises the entire value proposition, requiring rigorous quality control.

While lighter, the multi-layer plastic pouches used in retort can present more complex recycling challenges compared to infinitely recyclable metal or glass.

For Retort Furnaces

Retort furnaces are specialized, often expensive pieces of equipment that require skilled operators.

They typically operate in batches, which can result in lower throughput compared to continuous, open-atmosphere furnace systems.

The retort vessel itself is a consumable component that can degrade over time, especially under extreme temperatures, adding to operational costs.

Making the Right Choice for Your Goal

Your application will determine which "retort" is relevant and whether its advantages align with your needs.

- If your primary focus is creating high-quality, shelf-stable food products: Retort packaging offers a superior alternative to traditional canning by improving taste and nutrition while reducing logistical costs.

- If your primary focus is high-temperature material processing in a controlled environment: A retort furnace is essential for achieving specific properties and preventing contamination in applications from metallurgy to advanced ceramics.

Ultimately, whether for food or industrial materials, the retort process is defined by its ability to deliver superior quality through a precisely controlled, sealed environment.

Summary Table:

| Aspect | Retort Packaging (Food) | Retort Furnace (Industrial) |

|---|---|---|

| Primary Advantage | Shelf-stable quality without refrigeration | Precision material transformation in a controlled atmosphere |

| Key Benefit | Superior taste, texture, and nutrient retention | Prevents oxidation and contamination for sensitive materials |

| Process Type | Continuous sterilization and cooking | Batch processing |

| Main Application | Food preservation | Sintering, annealing, roasting powders in metallurgy, ceramics, and electronics |

Ready to harness the power of precision-controlled processing for your unique requirements?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Whether your needs align with the controlled environments of a retort furnace or another thermal processing challenge, our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your experimental and production goals.

Contact our experts today to discuss how we can develop a tailored solution that enhances your quality, efficiency, and results.

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems