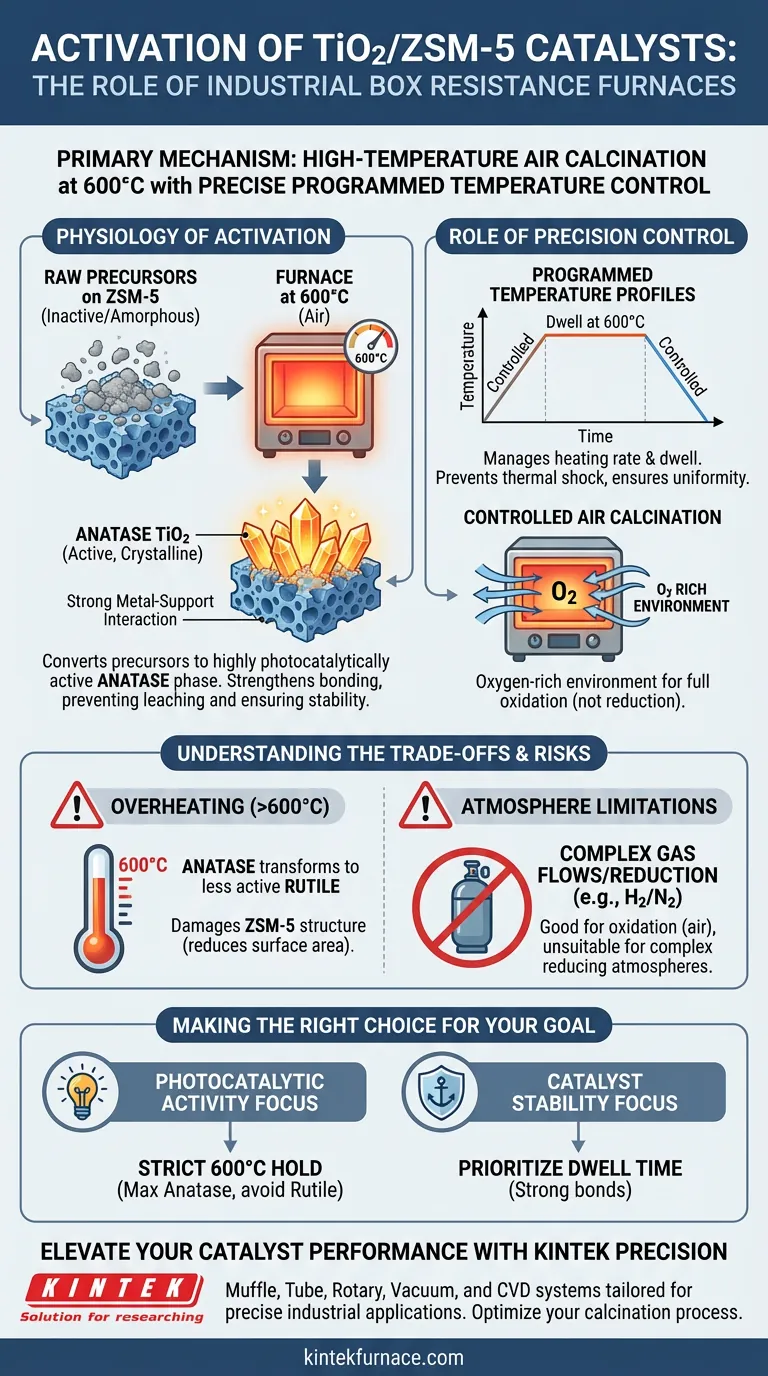

High-temperature air calcination is the primary mechanism by which an industrial box resistance furnace activates TiO2/ZSM-5 catalysts. By maintaining a precise thermal environment at 600 °C, the furnace facilitates the chemical conversion of titanium precursors into the photocatalytically active anatase phase while simultaneously anchoring these components to the ZSM-5 zeolite support.

The furnace’s critical role is not merely heating, but providing precise programmed temperature control. This ensures the formation of the specific anatase TiO2 phase and strengthens the metal-support interaction, resulting in a robust catalytic system that resists degradation.

The Physiology of Activation

To understand the furnace's contribution, one must look at the physical and chemical changes occurring within the catalyst structure during the 600 °C cycle.

Phase Transformation to Anatase

The raw titanium precursors loaded onto the zeolite are not yet active. The furnace provides the necessary thermal energy to drive a phase transition, converting these precursors into anatase TiO2.

This specific crystalline phase is crucial because it possesses the highest photocatalytic activity compared to other phases. Without reaching and maintaining 600 °C, the titanium would remain in an amorphous or inactive state, rendering the catalyst ineffective.

Strengthening Metal-Support Interactions

The furnace does more than just cook the titanium; it fuses the system together. The thermal treatment strengthens the interaction between the active TiO2 components and the ZSM-5 support structure.

This strong bonding is essential for the catalyst's longevity. It prevents the active components from leaching or detaching during operation, ensuring the resulting system is stable and mechanically robust.

The Role of Precision Control

The "box resistance" or "muffle" aspect of the furnace allows for a controlled atmospheric and thermal envelope, which is distinct from open-air heating or direct flame impingement.

Programmed Temperature Profiles

Activation is rarely a binary "on/off" heat process. These furnaces utilize programmed temperature control to manage the heating rate and dwell time.

This precision prevents thermal shock, which could crack the ZSM-5 support, and ensures that the heat distribution is uniform throughout the catalyst batch.

Controlled Air Calcination

The process specifically utilizes air calcination. The oxygen-rich environment within the box furnace is necessary to oxidize the precursors fully into titanium dioxide (TiO2).

This differs from reduction furnaces used for other catalyst types, where hydrogen atmospheres are required to strip oxygen away. For TiO2/ZSM-5, the goal is oxidation and crystallization.

Understanding the Trade-offs

While the box resistance furnace is the standard tool for this application, precise operation is required to avoid common pitfalls.

The Risk of Overheating

Temperature control must be exact. If the temperature significantly exceeds the 600 °C target, the TiO2 may transition from the active anatase phase to the stable but less active rutile phase.

Furthermore, excessive heat can damage the porous structure of the ZSM-5 zeolite, reducing the surface area available for catalytic reactions.

Atmosphere Limitations

Standard box muffle furnaces are designed for air or static atmospheres. They are excellent for oxidation (calcination) but are generally unsuitable for processes requiring complex gas flows or high-pressure reduction (e.g., creating pure metal phases using Hydrogen/Nitrogen mixes).

Making the Right Choice for Your Goal

When configuring your thermal treatment process for TiO2/ZSM-5, focus on the specific outcome you need to achieve.

- If your primary focus is Photocatalytic Activity: Ensure your furnace program holds strictly at 600 °C to maximize the formation of the anatase phase without triggering a transition to rutile.

- If your primary focus is Catalyst Stability: Prioritize the dwell time at the target temperature to allow sufficient energy for strong bonds to form between the TiO2 and the ZSM-5 support.

By leveraging the precise temperature control of an industrial box furnace, you transform raw precursors into a cohesive, high-performance catalytic system ready for industrial application.

Summary Table:

| Feature | Impact on TiO2/ZSM-5 Catalyst |

|---|---|

| 600°C Air Calcination | Converts precursors to the photocatalytically active anatase phase. |

| Programmed Control | Ensures uniform heating and prevents thermal shock to the ZSM-5 support. |

| Metal-Support Interaction | Strengthens bonding between TiO2 and zeolite to prevent leaching and degradation. |

| Atmosphere (Air) | Provides the oxygen-rich environment necessary for complete titanium oxidation. |

| Thermal Precision | Prevents the transition from active anatase to less active rutile phase. |

Elevate Your Catalyst Performance with KINTEK Precision

Don't let imprecise heating compromise your catalyst’s activity. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for precise industrial applications. Whether you need to maintain a strict 600°C for anatase phase stability or require custom thermal profiles for unique lab needs, our furnaces provide the uniform heat distribution and advanced control your research demands.

Ready to optimize your calcination process? Contact us today to find the perfect customizable furnace for your laboratory or industrial production.

Visual Guide

References

- Wibawa Hendra Saputera, Dwiwahju Sasongko. Understanding the Role of Copper Oxidation State on a TiO<sub>2</sub>/ZSM‐5 Catalyst for Photocatalytic CO<sub>2</sub> Reduction to Methanol. DOI: 10.1002/admi.202500010

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What additional functionalities does an atmosphere furnace offer compared to a muffle furnace? Unlock Advanced Material Processing

- What are the research and development applications of retort furnaces? Unlock Precise High-Temperature Material Control

- What gases are commonly used in heat treatment furnace atmospheres? Optimize Your Process with the Right Gas Mix

- Can the reducing atmosphere be replaced with other gaseous mediums? Explore Advanced Surface Engineering Solutions

- What is the purpose of switching between N2 and H2 in electrical steel annealing? Master Atmosphere Control

- What is the significance of a controlled atmosphere in a retort furnace? Ensure Purity and Precision in Thermal Processing

- What is the purpose of introducing a nitrogen protective atmosphere during the continuous annealing of silicon steel?

- What are the advantages of an atmosphere box furnace in the preparation and sintering of ceramic materials? Achieve Precise Control for Superior Ceramics