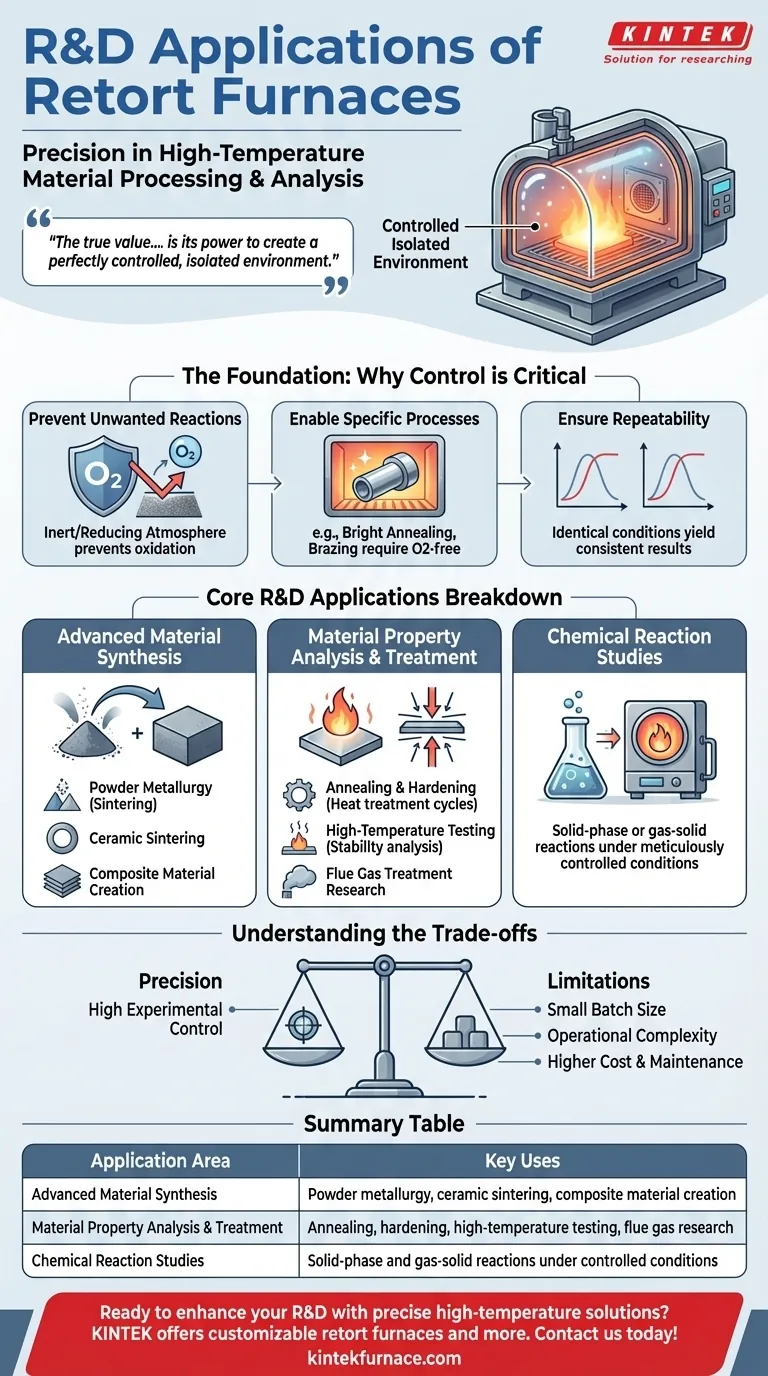

In research and development, a retort furnace is used for high-temperature material processing and analysis where precise control over the atmosphere is non-negotiable. These furnaces are indispensable in university, government, and industrial labs for creating new materials, studying chemical reactions, and testing material properties in environments free from oxygen and other contaminants.

The true value of a retort furnace in an R&D setting is not just its ability to get hot, but its power to create a perfectly controlled, isolated environment. This control is the key to developing advanced materials and achieving repeatable, scientifically valid experimental results.

The Foundation of R&D: Why Control is Critical

In any research environment, the goal is to isolate variables to understand cause and effect. A retort furnace provides an enclosed, sealed chamber (the retort) that allows a researcher to control both temperature and the gaseous atmosphere with extreme precision.

Preventing Unwanted Reactions

Many advanced materials, especially metals and alloys, are highly reactive with oxygen at high temperatures. This oxidation can ruin an experiment or fundamentally alter the properties of the material being developed.

A retort furnace allows for the purging of ambient air and the introduction of an inert atmosphere (like argon or nitrogen) or a reducing atmosphere (like hydrogen). This prevents unwanted chemical reactions, ensuring the material's integrity.

Enabling Specific Processes

Certain material treatments are only possible in a specific atmosphere. For example, bright annealing of stainless steel, which maintains a shiny, oxide-free surface, requires an oxygen-free environment.

Similarly, processes like furnace brazing rely on a controlled atmosphere to ensure the filler metal flows correctly and forms a strong, clean joint without oxidation.

Ensuring Repeatability

Scientific progress depends on the ability to repeat experiments and get the same results. By providing exact control over temperature ramps, soak times, and gas composition, retort furnaces ensure that experimental conditions are identical from one run to the next.

Core R&D Applications Breakdown

The ability to control the processing environment makes retort furnaces suitable for a wide range of R&D applications.

Advanced Material Synthesis

Retort furnaces are at the heart of developing next-generation materials. This includes:

- Powder Metallurgy: Creating parts from metal powders by heating them below their melting point (sintering) in a controlled atmosphere to prevent oxidation and ensure proper bonding.

- Ceramic Sintering: Firing ceramic powders to create a dense, solid material. The atmosphere can influence the final grain structure and properties.

- Composite Material Creation: Developing new composites by bonding different materials together under specific heat and atmospheric conditions.

Material Property Analysis & Treatment

Researchers use these furnaces to test and modify the characteristics of materials.

- Annealing and Hardening: Studying how different heat treatment cycles, performed in a controlled atmosphere, affect a material's hardness, ductility, and internal stresses.

- High-Temperature Testing: Subjecting materials to extreme heat in a specific atmosphere to analyze their stability, degradation, or performance for applications like aerospace components.

- Flue Gas Treatment Research: Simulating and studying the effects of different gas mixtures on materials at high temperatures.

Chemical Reaction Studies

For chemists and material scientists, a retort furnace acts as a contained, high-temperature reactor. It enables the study of solid-phase or gas-solid reactions under meticulously controlled conditions, providing fundamental insights for scientific discovery.

Understanding the Trade-offs

While powerful, retort furnaces are a specialized tool, and choosing one involves understanding their limitations.

Batch Size vs. Precision

Most R&D retort furnaces are designed for experimental scale, prioritizing precision over volume. Their batch size is often smaller than industrial production furnaces, making them ideal for testing and development but not mass manufacturing.

Operational Complexity

Operating a retort furnace involves more steps than a simple box furnace. The process of sealing the retort, performing vacuum purges, and managing gas flow systems requires careful training and adds to the operational overhead.

Cost and Maintenance

The sealed retort, vacuum systems, and gas delivery plumbing add to the initial cost and long-term maintenance of the furnace. The retort itself is often a consumable component that may need replacement over time, especially when used at extreme temperatures.

Matching the Furnace to Your Research Goal

To select the right approach, align the equipment's capability with your primary objective.

- If your primary focus is developing new alloys or powders sensitive to oxygen: You absolutely require a retort furnace to create the necessary inert or reducing atmosphere.

- If your primary focus is testing the heat treatment response of existing materials: A retort furnace provides the repeatable control needed to generate scientifically valid performance curves.

- If your primary focus is sintering advanced ceramics or composites: The uniform heating and atmospheric control of a retort furnace are critical for achieving desired densification and final properties.

Ultimately, choosing a retort furnace is a decision to prioritize environmental control to unlock new possibilities in material science and chemical research.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Advanced Material Synthesis | Powder metallurgy, ceramic sintering, composite material creation |

| Material Property Analysis & Treatment | Annealing, hardening, high-temperature testing, flue gas research |

| Chemical Reaction Studies | Solid-phase and gas-solid reactions under controlled conditions |

Ready to enhance your R&D with precise high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced retort furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for material synthesis and analysis. Contact us today to discuss how our solutions can drive your innovations forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents