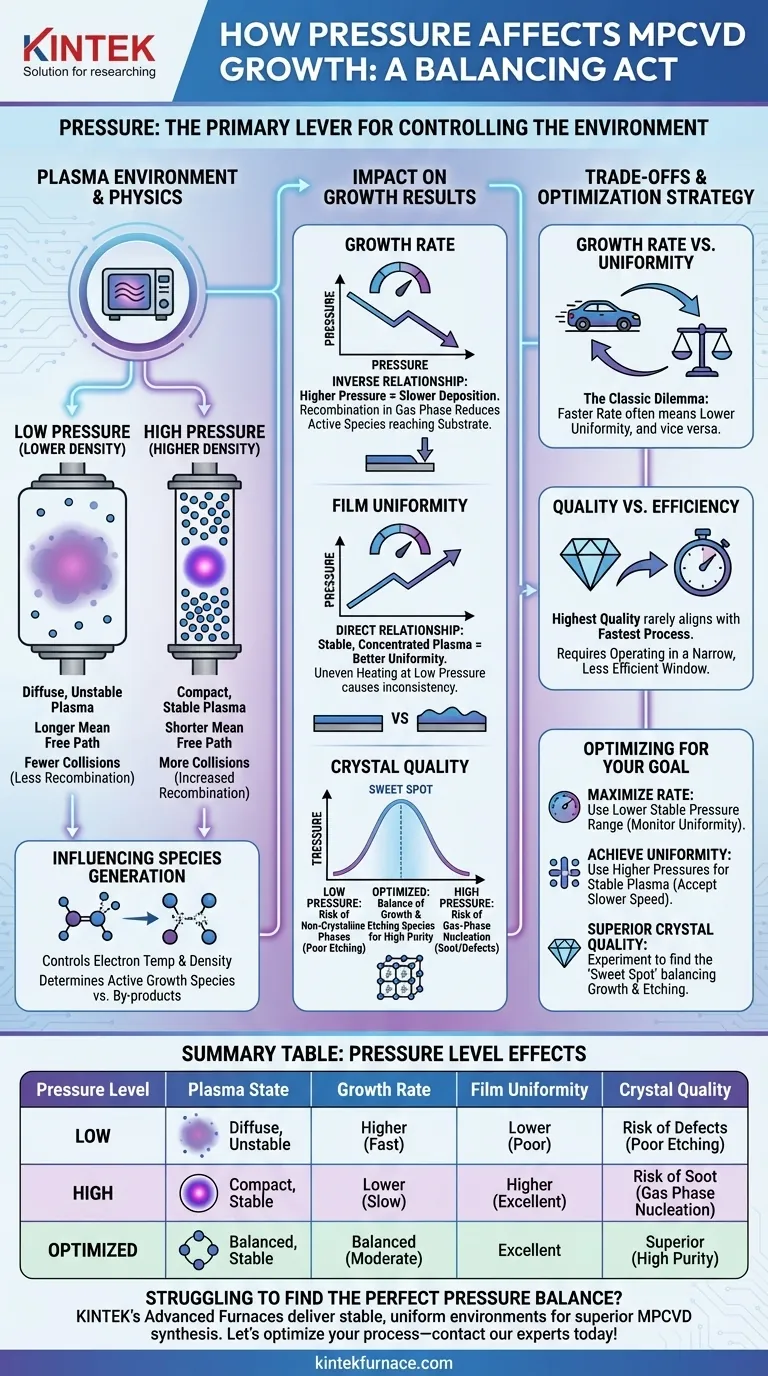

In MPCVD, pressure is the primary lever for controlling the entire growth environment. It directly governs the density of precursor gases, the physical shape and stability of the plasma, and the chemical pathways that lead to film deposition. The pressure you choose determines the balance between growth rate, film uniformity, and overall material quality.

At its core, pressure in Microwave Plasma Chemical Vapor Deposition (MPCVD) is a balancing act. You must maintain enough pressure to generate a dense, stable plasma for efficient chemical reactions, but not so much that you starve the substrate of the active species required for growth.

The Role of Pressure in the Plasma Environment

To understand how pressure impacts your final material, you must first understand how it shapes the plasma itself. The plasma is the engine of the MPCVD process, and pressure is its throttle.

Defining the Plasma Ball

Pressure dictates the physical size and location of the plasma. At lower pressures, the plasma expands to fill more of the chamber, becoming diffuse and sometimes unstable.

At higher pressures, gas molecules confine the plasma, causing it to shrink into a smaller, more intense, and more stable ball centered in the microwave field. This directly impacts where and how evenly energy is delivered to the substrate.

Controlling Gas Density and Mean Free Path

Pressure is a direct measure of gas density. Higher pressure means more gas molecules are packed into the chamber.

This increased density dramatically shortens the mean free path—the average distance a particle travels before colliding with another. A short mean free path means more collisions happen in the gas phase above the substrate.

Influencing Species Generation

The frequency and energy of collisions determine which chemical species are created. Pressure influences the plasma's electron temperature and density, which in turn controls the dissociation of precursor gases (e.g., methane and hydrogen for diamond growth).

The right pressure window creates a high concentration of the desired active growth species (like CH₃ radicals and atomic hydrogen) while minimizing the creation of undesirable ones.

How Pressure Directly Impacts Growth Results

The changes within the plasma environment have direct, measurable consequences on the film you are growing.

The Effect on Growth Rate

The growth rate is highly sensitive to pressure. Counter-intuitively, increasing pressure often slows deposition.

This is because a shorter mean free path leads to more recombination of active species in the gas phase. They neutralize each other before they can ever reach the substrate surface to contribute to growth.

The Effect on Film Uniformity

Uniformity is primarily a function of plasma shape and stability. Low pressures can cause the plasma to become large and unstable, leading to uneven heating and inconsistent delivery of species across the substrate.

Conversely, higher pressures create a stable, concentrated plasma. This promotes excellent uniformity across the area directly beneath it but may limit the total usable deposition area.

The Impact on Crystal Quality

Pressure is critical for achieving high crystal quality and purity. If the pressure is too high, gas-phase nucleation can occur, forming powder or "soot" that incorporates into the film as defects.

If the pressure is too low, you may not generate enough etching agents (like atomic hydrogen in diamond synthesis) to remove lower-quality, non-crystalline phases (like graphite) from the growing surface.

Understanding the Trade-offs

Optimizing pressure is never about a single metric; it is about managing a set of critical trade-offs.

Growth Rate vs. Uniformity

This is the classic MPCVD dilemma. Lower pressures can provide a faster growth rate but often at the expense of film uniformity. Higher pressures deliver superior uniformity but typically slow the process down considerably.

Quality vs. Efficiency

The pressure that yields the fastest growth is rarely the same pressure that produces the highest crystal quality. Achieving pristine material often requires operating in a specific, narrower pressure window that ensures a proper balance of growth and etching species, even if it is less efficient.

Preventing Unwanted By-products

The wrong pressure can actively work against you. Too high, and you risk creating soot in the gas phase. Too low, and you risk being unable to etch away graphitic or amorphous by-products that form on the substrate, severely compromising film purity.

Optimizing Pressure for Your Specific Goal

There is no single "best" pressure; the optimal setting depends entirely on your primary objective. Use these principles as a guide for your process development.

- If your primary focus is maximizing growth rate: Operate at the lower end of your process's stable pressure range, but be prepared to actively monitor and compensate for potential non-uniformity.

- If your primary focus is achieving the highest film uniformity: Use higher pressures to create a compact and stable plasma, accepting the inherent reduction in growth speed.

- If your primary focus is obtaining superior crystal quality: Methodically experiment to find the "sweet spot" pressure that balances sufficient growth species with effective etching of defects.

Mastering pressure gives you precise control over the fundamental physics of your material growth.

Summary Table:

| Pressure Level | Plasma State | Growth Rate | Film Uniformity | Crystal Quality |

|---|---|---|---|---|

| Low | Diffuse, Unstable | Higher | Lower | Risk of Defects |

| High | Compact, Stable | Lower | Higher | Risk of Soot |

| Optimized | Balanced, Stable | Balanced | Excellent | Superior |

Struggling to find the perfect pressure balance for your MPCVD process? KINTEK's advanced high-temperature furnace solutions, including our precisely controlled Tube and Vacuum & Atmosphere Furnaces, are engineered to deliver the stable, uniform environments required for superior MPCVD synthesis. Leveraging our exceptional R&D and deep customization capabilities, we tailor our systems to meet your unique experimental requirements, ensuring optimal growth rates, film uniformity, and crystal quality. Let's optimize your process—contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- In which industries is MPCVD commonly used? Essential for High-Performance Electronics, Optics, and More

- What are the key features of MPCVD single crystal diamond deposition equipment? Precision Control for High-Quality Growth

- What are the advantages of MPCVD in terms of industrial applications? Scale High-Performance Material Production

- Why is the MPCVD method considered the most promising for industrial diamond synthesis? Discover Its Unmatched Purity and Control

- How does the MPCVD method create plasma for diamond film deposition? Discover the Key to High-Purity Diamond Synthesis

- What are some challenges associated with MPCVD? Overcome High Costs and Complexity for Diamond Synthesis

- How should the cooling water system of MPCVD equipment be maintained? Ensure Stability and Longevity for Your Lab

- What is Microwave Plasma Chemical Vapor Deposition (MPCVD) and what is its primary use?