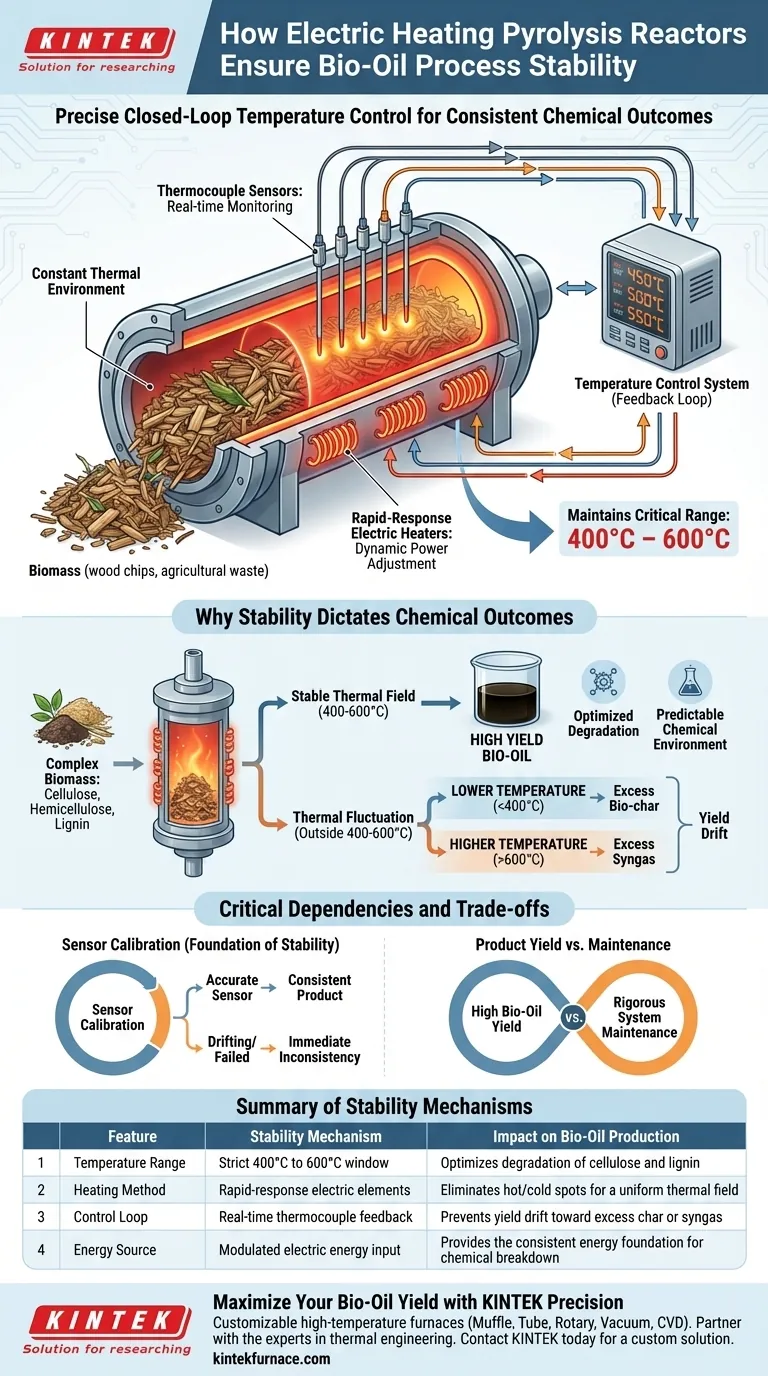

An electric heating pyrolysis reactor ensures stability through a precise, closed-loop temperature control system. By utilizing sensitive thermocouple sensors to continuously monitor internal conditions, the system dynamically adjusts the electric heating elements to maintain a constant thermal environment. This mechanism locks the reactor within the critical 400°C to 600°C range, effectively eliminating thermal fluctuations that would otherwise disrupt the chemical process.

Core Takeaway Achieving high-quality bio-oil requires more than just heat; it requires a stable thermal "field." The electric heating reactor provides this by coupling precision sensors with rapid-response electric heaters, ensuring the consistent energy foundation necessary to chemically degrade biomass into oil rather than waste char or gas.

The Mechanics of Thermal Stability

The Role of Thermocouple Sensors

To maintain stability, the reactor relies on a network of thermocouple sensors. These sensors act as the "eyes" of the system, providing real-time data on the internal reactor temperature.

Creating a Constant Thermal Environment

Based on the feedback from the sensors, the temperature control system modulates the electric energy input. This creates a constant high-temperature field, preventing the hot and cold spots common in less precise heating methods.

The 400°C to 600°C Window

The system is specifically calibrated to hold the temperature strictly between 400°C and 600°C. Maintaining this specific window is the primary operational goal of the electric heating stability mechanism.

Why Stability Dictates Chemical Outcomes

Degrading Complex Biomass

The stability of the reactor provides the necessary energy foundation for the thermochemical degradation of biomass components. Specifically, this consistent heat is required to break down cellulose, hemicellulose, and lignin effectively.

Controlling Product Distribution

Stability is not just about safety; it determines what you produce. The precise control of temperature directly dictates the final distribution of the three main byproducts: bio-oil, bio-char, and syngas.

Preventing Yield Drift

Without this electric precision, the reaction might drift toward producing excess char (at lower temperatures) or syngas (at higher temperatures). The electric reactor ensures the process stays in the "bio-oil zone."

Critical Dependencies and Trade-offs

Reliance on Sensor Calibration

The stability of the entire process is heavily dependent on the accuracy of the thermocouple sensors. If these sensors drift or fail, the "precise temperature control" foundation collapses, leading to immediate inconsistencies in the product.

The Sensitivity of Product Yield

Because the distribution of bio-oil, char, and syngas is directly determined by temperature control, there is little room for error. The trade-off for high bio-oil yield is the requirement for rigorous maintenance of the thermal control system.

Making the Right Choice for Your Goal

To maximize the efficiency of your bio-oil production, you must align your operational parameters with the capabilities of the electric heating system.

- If your primary focus is maximizing Bio-oil Yield: Ensure your control system is calibrated to hold the temperature strictly within the middle of the 400°C–600°C range to optimize cellulose degradation.

- If your primary focus is Process Consistency: Prioritize the regular calibration of thermocouple sensors, as they are the single point of truth for maintaining the required thermal field.

True process stability creates the predictable chemical environment required to turn raw biomass into valuable energy resources.

Summary Table:

| Feature | Stability Mechanism | Impact on Bio-Oil Production |

|---|---|---|

| Temperature Range | Strict 400°C to 600°C window | Optimizes degradation of cellulose and lignin |

| Heating Method | Rapid-response electric elements | Eliminates hot/cold spots for a uniform thermal field |

| Control Loop | Real-time thermocouple feedback | Prevents yield drift toward excess char or syngas |

| Energy Source | Modulated electric energy input | Provides the consistent energy foundation for chemical breakdown |

Maximize Your Bio-Oil Yield with KINTEK Precision

Achieving consistent chemical outcomes in biomass pyrolysis requires uncompromising thermal stability. KINTEK delivers high-performance heating solutions backed by expert R&D and manufacturing, ensuring your research or production stays locked in the "bio-oil zone."

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temperature furnaces are fully customizable to meet your unique process stability requirements. Don't let thermal fluctuations compromise your results—partner with the experts in thermal engineering.

Ready to optimize your pyrolysis process? Contact KINTEK today for a custom solution.

Visual Guide

References

- Haniif Prasetiawan, R Fitrah. The Effect of Raw Material Composition and Pyrolysis Temperature on The Characteristics of Bio-Oil from the Pyrolysis of Sawdust and Sugar Cane Bagasse Mixture. DOI: 10.1051/e3sconf/202564803007

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

People Also Ask

- What are the key features and benefits of rotary tube furnaces? Achieve Superior Uniform Heating for Powders and Granules

- What are the key components and parameters of a rotary kiln? Optimize Your High-Temperature Processing

- How do rotary kilns handle variations in feedstock? Leverage Design and Control for Consistency

- What are the zones inside the rotary kiln cylinder? Unlock Efficient Material Processing

- What advanced features do modern rotary kilns include? Boost Efficiency with Smart, Precise Thermal Control

- What are the differences between direct and indirect rotary kilns? Choose the Right Kiln for Your Material

- What is the purpose of the rotating device in a rotary tube furnace? Achieve Uniform Heating and Efficient Mixing

- What are the primary functions of rotary kilns? Key Roles in Industrial Processing Explained