At their core, rotary kilns are industrial workhorses designed for a single, critical purpose: to heat bulk solids to extremely high temperatures. This controlled heating induces a specific chemical reaction or a physical phase change. They are the primary tools used for processes like calcination to produce cement, thermal desorption to clean contaminated soils, and the reduction of ores to extract valuable metals.

The challenge for many industries is achieving uniform, high-temperature processing for vast quantities of granular materials. A rotary kiln solves this by uniquely combining rotation, inclination, and controlled heating, creating a dynamic environment that ensures every particle is processed consistently, transforming raw materials into valuable products.

How a Rotary Kiln Achieves its Function

A rotary kiln's effectiveness comes not from a single component, but from the elegant interplay of its core design principles. It is a system engineered for continuous, uniform material processing at scale.

The Principle of Controlled Tumbling

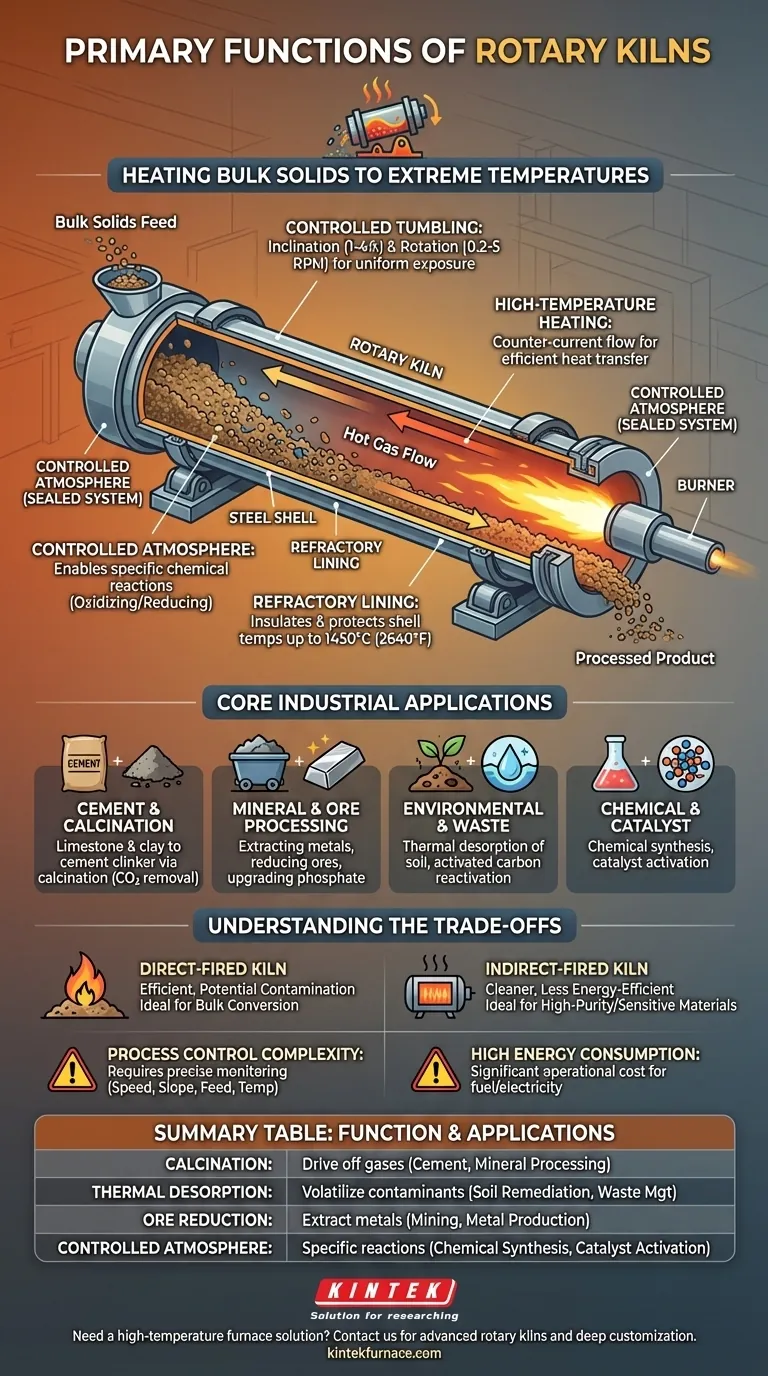

A rotary kiln is a long, steel cylinder lined with heat-resistant material, known as refractory. It is mounted at a slight angle (1-4% slope) and rotates slowly (typically 0.2 to 5 revolutions per minute).

This combination of inclination and rotation is the key to its function. It causes the material fed into the higher end to gently and continuously tumble its way to the lower, discharge end, ensuring all particles are evenly exposed to the heat.

The Role of High-Temperature Heating

Heat is the catalyst for the transformation. In most designs, a powerful burner is located at the discharge end, firing into the kiln.

This creates a counter-current flow, where the hot gases from the burner travel up the kiln against the flow of the material moving down. This is a highly efficient method of heat transfer, as the hottest gases meet the most processed material, and the cooler gases preheat the new material entering the kiln.

The Importance of a Controlled Atmosphere

Kilns are sealed at both ends. These seals are critical for two reasons: containing the internal atmosphere and improving thermal efficiency.

Controlling the atmosphere allows for specific chemical reactions. For example, a process might require an oxidizing (oxygen-rich) or reducing (oxygen-starved) environment, which is only possible in a sealed system.

The Critical Refractory Lining

The internal refractory lining is the kiln's essential protective layer. It insulates the steel shell from extreme process temperatures, which can exceed 1450°C (2640°F) in cement production.

This insulation minimizes heat loss to the environment, making the process more energy-efficient, and protects the structural integrity of the kiln itself.

Core Industrial Applications

The rotary kiln's versatile design makes it indispensable across a range of heavy industries. Its function is defined by the material being processed and the desired outcome.

Cement Production and Calcination

This is the most well-known application. Rotary kilns heat a mixture of limestone and clay to create cement clinker. The high temperature drives off carbon dioxide from the limestone in a process called calcination, a fundamental chemical change required to produce cement.

Mineral and Ore Processing

In the mining industry, kilns are used to extract metals from ores. This can involve heating ores to drive off water, reduce oxides to their base metals, or otherwise prepare them for further refinement. Upgrading phosphate ore for agricultural fertilizers is another common use.

Environmental and Waste Management

Rotary kilns are powerful tools for remediation. They are used for thermal desorption, where heat volatilizes and removes harmful contaminants from soil. They are also used to reactivate activated carbon, burning off impurities so the carbon can be reused for air and water purification.

Chemical and Catalyst Manufacturing

The ability to control both temperature and atmosphere makes kilns ideal for synthesizing certain chemicals. They are also used to activate catalysts, which are substances that speed up chemical reactions in other manufacturing processes.

Understanding the Trade-offs

While incredibly effective, a rotary kiln is a complex piece of industrial equipment with operational trade-offs that must be managed.

Direct vs. Indirect Heating

Most large kilns are direct-fired, meaning the material is in direct contact with the burner's flame and combustion gases. This is very thermally efficient but can lead to contamination.

For high-purity or sensitive materials, an indirect-fired kiln is used. In this design, the rotating cylinder is heated from the outside, keeping the material isolated from combustion gases. This process is cleaner but less energy-efficient and limited in its maximum temperature.

Process Control Complexity

Product quality depends on a precise balance of variables. Rotation speed, kiln slope, feed rate, and the temperature profile along the kiln's length must be carefully monitored and controlled. A slight deviation in any one of these can impact the final product.

High Energy Consumption

Bringing tons of material up to thousands of degrees requires an immense amount of energy. Fuel for the burner (or electricity for electric kilns) represents a significant operational cost. Optimizing thermal efficiency is a primary goal for any kiln operator.

Making the Right Choice for Your Goal

The optimal kiln configuration is dictated entirely by the process objective.

- If your primary focus is bulk material conversion like cement: A large, direct-fired, counter-current kiln is required for maximum throughput and thermal efficiency.

- If your primary focus is producing a high-purity chemical: An indirect-fired kiln is necessary to prevent contamination from combustion byproducts.

- If your primary focus is environmental remediation: Precise control over temperature zones and residence time is critical to ensure complete destruction or removal of contaminants.

Ultimately, mastering the rotary kiln is about understanding how its fundamental principles of motion and heat can be tuned to transform raw potential into a valuable, finished product.

Summary Table:

| Function | Key Process | Common Applications |

|---|---|---|

| Calcination | Heating to drive off gases | Cement production, mineral processing |

| Thermal Desorption | Volatilizing contaminants | Soil remediation, waste management |

| Ore Reduction | Extracting metals from ores | Mining, metal production |

| Controlled Atmosphere Processing | Enabling specific chemical reactions | Chemical synthesis, catalyst activation |

Need a high-temperature furnace solution tailored to your industrial needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced rotary kilns, muffle furnaces, tube furnaces, and more, with deep customization for precise experimental requirements. Contact us today to enhance your processing efficiency and achieve superior results!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- How do vibrational feeder specifications impact rotary kiln efficiency? Optimize Your Lab's Material Flow & Stability

- What are the primary applications of an electric rotary kiln? Achieve High-Purity Material Processing with Precision

- What role does gas flow and combustion play in a rotary kiln? Optimize Heat Transfer for Efficiency and Quality

- What distinguishes direct from indirect rotary kilns? Choose the Right Kiln for Your Material