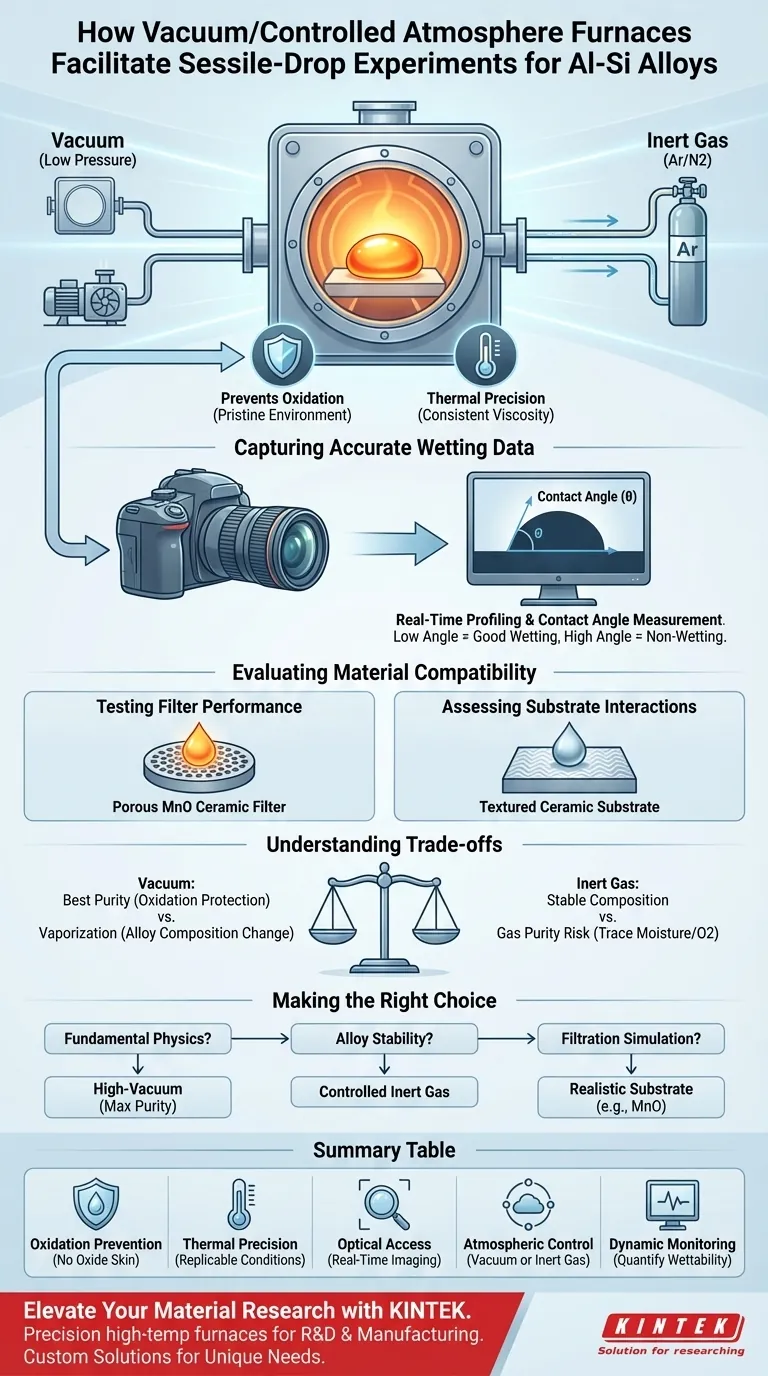

A vacuum or controlled atmosphere furnace facilitates sessile-drop experiments by establishing the pristine environment required to accurately measure wetting properties.

By melting aluminum-silicon alloy samples on ceramic substrates under low-pressure or inert gas conditions, these furnaces prevent surface oxidation. This controlled environment, combined with high-resolution imaging systems, enables the real-time capture of droplet profiles to calculate precise contact angles.

By eliminating atmospheric interference, these furnaces ensure that the measured interaction between the molten alloy and the substrate reflects true material properties rather than artifacts caused by oxide skin formation.

Creating the Optimal Experimental Environment

Preventing Oxidation

Aluminum and its alloys are highly reactive to oxygen, forming a tough oxide skin almost instantly in air.

A vacuum or controlled atmosphere furnace eliminates oxygen from the chamber.

This ensures the molten droplet remains pure, allowing for valid measurements of how the liquid metal interacts with the solid substrate.

Thermal Precision

These furnaces provide the high-temperature capabilities necessary to melt aluminum-silicon alloys completely.

Precise thermal control ensures the sample reaches the correct viscosity without overheating, which is critical for replicating specific casting or filtration conditions.

Capturing Accurate Wetting Data

Real-Time Droplet Profiling

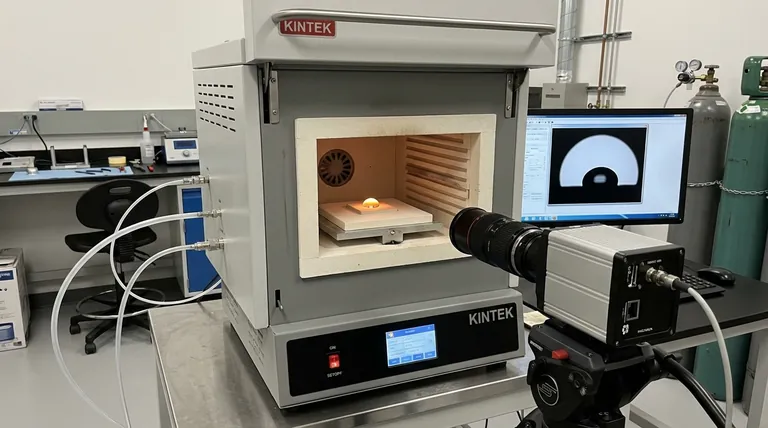

The furnace setup includes optical access for high-resolution imaging systems.

These cameras record the silhouette of the alloy sample as it transitions from solid to liquid.

This real-time monitoring allows researchers to observe the dynamic changes in the droplet's shape as it reaches equilibrium.

Measuring Contact Angles

The core metric derived from these experiments is the contact angle—the angle at which the liquid interface meets the solid surface.

Imaging software analyzes the captured droplet profiles to quantify this angle.

This data is the definitive indicator of wettability: a lower angle indicates good wetting (spreading), while a high angle indicates non-wetting behavior.

Evaluating Material Compatibility

Testing Filter Performance

Beyond basic alloy characterization, these furnaces are used to evaluate specific industrial applications, such as filtration.

For example, researchers use this method to test how aluminum melts interact with materials like manganese oxide (MnO) ceramic filters.

Assessing Substrate Interactions

The experiment simulates the physical conditions the alloy will face during processing.

By melting the alloy on specific ceramic substrates, engineers can predict how the melt will adhere to or flow through porous media in actual casting scenarios.

Understanding the Trade-offs

Vacuum vs. Vapor Pressure

While high vacuum offers the best protection against oxidation, it can cause issues with volatile alloying elements.

If the pressure is too low, certain elements within the aluminum alloy may vaporize at melting temperatures, altering the alloy's composition during the test.

Inert Gas Complexity

Using an inert gas atmosphere avoids vaporization issues but introduces variables regarding gas purity.

Even trace amounts of moisture or oxygen in the inert gas stream can compromise the surface of the aluminum droplet, skewing contact angle results.

Making the Right Choice for Your Goal

To maximize the value of your sessile-drop experiments, align your furnace settings with your specific research objectives.

- If your primary focus is fundamental wetting physics: Prioritize high-vacuum environments to ensure the absolute highest purity of the interface, minimizing oxide interference.

- If your primary focus is alloy composition stability: Opt for a controlled inert gas atmosphere to prevent the evaporation of volatile elements while still suppressing oxidation.

- If your primary focus is filtration simulation: Ensure the substrate material in the furnace matches your industrial filter media (e.g., manganese oxide) to capture realistic interaction data.

Accurate characterization of high-temperature wetting relies not just on the measurement tools, but on the absolute integrity of the atmosphere surrounding the sample.

Summary Table:

| Feature | Benefit in Sessile-Drop Experiments |

|---|---|

| Oxidation Prevention | Eliminates oxide skin for true liquid-solid interaction measurement. |

| Thermal Precision | Ensures consistent viscosity and replicable casting/filtration conditions. |

| Optical Access | Allows real-time high-resolution imaging of droplet silhouettes. |

| Atmospheric Control | Choice of vacuum or inert gas to balance purity with alloy stability. |

| Dynamic Monitoring | Enables calculation of contact angles to quantify material wettability. |

Elevate Your Material Research with KINTEK

Precision in high-temperature wetting analysis starts with the integrity of your experimental environment. KINTEK provides industry-leading R&D and manufacturing expertise, offering a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are testing filter performance or fundamental alloy physics, our lab high-temp furnaces are fully customizable to meet your unique experimental needs.

Ready to achieve superior thermal control and accurate data?

Contact KINTEK experts today for a custom solution

Visual Guide

References

- Hanka Becker, Andreas Leineweber. Reactive Interaction and Wetting of Fe‐ and Mn‐Containing, Secondary AlSi Alloys with Manganese Oxide Ceramic Filter Material for Fe Removal. DOI: 10.1002/adem.202500636

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the endothermic gas in heat treatment? Master Carbon Control for Superior Steel Hardening

- What are the applications of an atmosphere box furnace in environmental protection and new energy? Unlock Controlled Heat Solutions

- What are the operational advantages of using a controlled atmosphere furnace? Boost Quality and Efficiency in Heat Treatment

- What are sealed atmosphere furnaces called and what are their features? Discover Precision Heat Treatment Solutions

- What safety features are incorporated into experimental box type atmosphere furnaces? Essential Protections for Hazardous Gas and Heat

- What role does a high-temperature annealing furnace play in aluminum-silicon pressure sensor production?

- How are atmosphere furnaces used in material processing? Master Precise Heat Treatment for Superior Materials

- What is the significance of the preheating step using a high-temperature furnace? Ensure Pellets Strength and Integrity