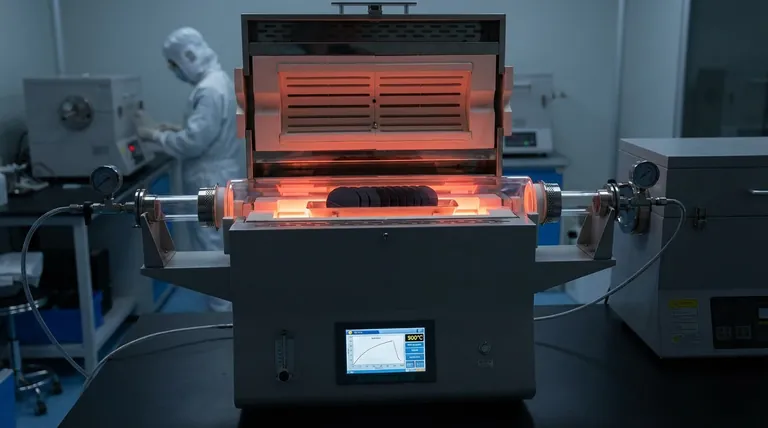

The high-temperature annealing furnace serves as the critical activation and repair station in the manufacturing of aluminum-silicon hybrid pressure sensors. Specifically, it subjects implanted wafers to temperatures of 900°C for roughly 30 minutes to transform the raw silicon structure into a functional sensing element.

Core Takeaway Use of this furnace is not merely for drying or heating; it is a fundamental chemical processing step. It activates dopant atoms and repairs crystal lattice damage, ensuring the piezoresistive strips possess the electrical stability and sensitivity required for accurate pressure measurement.

The Mechanism of Sensor Activation

Activating Injected Dopant Atoms

During earlier production stages, dopant atoms (such as boron) are injected into the silicon. Initially, these atoms are electrically inactive.

The annealing furnace provides the thermal energy required to move these dopant atoms into the correct positions within the crystal lattice. This "activation" allows the material to conduct electricity precisely as engineered.

Repairing Lattice Damage

The process of ion implantation is physically aggressive and damages the silicon crystal structure.

High-temperature treatment at 900°C allows the silicon lattice to heal itself. This restoration of the crystal structure is vital for eliminating defects that could cause signal noise or mechanical failure.

Ensuring Uniform Distribution

Consistency is paramount for sensor accuracy. The furnace ensures that the boron ions diffuse evenly throughout the silicon layer.

This uniformity stabilizes the electrical performance of the piezoresistive strips. Without it, the sensor would exhibit unpredictable variations in sensitivity across its surface.

Secondary Functions in Assembly

Curing Electrode Connections

Beyond the silicon treatment, high-temperature furnaces play a role in establishing electrical connectivity.

They provide the environment necessary to solidify and cure gold paste electrodes. At these temperatures, organic components in the paste volatilize, leaving behind a pure conductive path.

Enhancing Component Adhesion

The annealing process facilitates the sintering of gold particles into a continuous film.

This significantly enhances the adhesion between the gold electrode and the ceramic substrate. Strong adhesion is critical for ensuring the long-term stability of signal acquisition, preventing delamination over time.

Understanding the Process Trade-offs

Thermal Budget Management

While high temperatures are necessary for silicon repair, they impose strict constraints on the materials used.

Since aluminum has a melting point below the 900°C annealing temperature, this furnace step must occur before any aluminum metallization or interconnects are applied. Poor sequencing will result in catastrophic component failure.

Diffusion Control Risks

Time and temperature must be balanced with extreme precision.

If the wafers remain in the furnace too long, the dopant atoms may diffuse beyond the intended depth. This "over-diffusion" changes the electrical resistance profiles, potentially pushing the sensor outside of its required specifications.

Optimizing Production for Quality

To ensure the reliability of aluminum-silicon hybrid sensors, the annealing process must be tailored to specific performance goals.

- If your primary focus is Electrical Stability: Prioritize the 900°C maintenance phase to ensure complete activation of boron ions and thorough lattice repair.

- If your primary focus is Signal Integrity: Ensure the ramp-down and electrode curing phases are optimized to create solid, highly conductive gold film connections.

Ultimately, the annealing furnace is the gatekeeper that determines whether a wafer becomes a high-precision instrument or a rejected component.

Summary Table:

| Process Phase | Primary Function | Key Outcome |

|---|---|---|

| Dopant Activation | Thermal energy for lattice placement | Precise electrical conductivity |

| Lattice Repair | Healing ion-implantation damage | Reduced signal noise & mechanical failure |

| Electrode Curing | Volatilization of organic pastes | Pure, high-adhesion gold connections |

| Diffusion Control | Precise time/temp management | Consistent resistance profiles |

Precision Heat Treatment for Next-Gen Sensing

At KINTEK, we understand that in the production of aluminum-silicon hybrid sensors, the furnace is more than a tool—it's the gatekeeper of quality. Backed by expert R&D and manufacturing, KINTEK offers a wide range of high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous thermal budgets of your specific semiconductor or sensing applications.

Ensure maximum yield, superior electrical stability, and perfect lattice restoration with our lab-grade high-temperature solutions. Consult with a KINTEK specialist today to optimize your manufacturing flow.

References

- Min Li, Wenhao Hua. Development of Highly Sensitive and Thermostable Microelectromechanical System Pressure Sensor Based on Array-Type Aluminum–Silicon Hybrid Structures. DOI: 10.3390/mi15091065

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a controlled atmosphere annealing furnace influence the stability of retained austenite? Unlock Steel Quality

- Why is a protective atmosphere annealing furnace required for treating Alumina Dispersion Strengthened Copper (ADSC) rods after the hot extrusion process? Ensure Dimensional Stability and Oxidation-Free Results

- How are atmosphere furnaces utilized in semiconductor manufacturing? Essential for Annealing, Diffusion, and CVD Processes

- What is the function of a high-temperature annealing furnace for Al-7075? Optimize Ductility and Microstructure

- What is the role of an industrial convection air furnace in constructing Nitinol TTS curves? Achieve Precise Heat Treatment

- How does the heating system of a program-controlled atmosphere furnace work? Unlock Precision Heating for Your Lab

- What is the function of a high-temperature pyrolysis furnace in the preparation of magnetic Fe3O4/biochar nanoparticles?

- How does an industrial high-temperature furnace simulate the blast furnace reduction environment? Achieve 30% Reduction