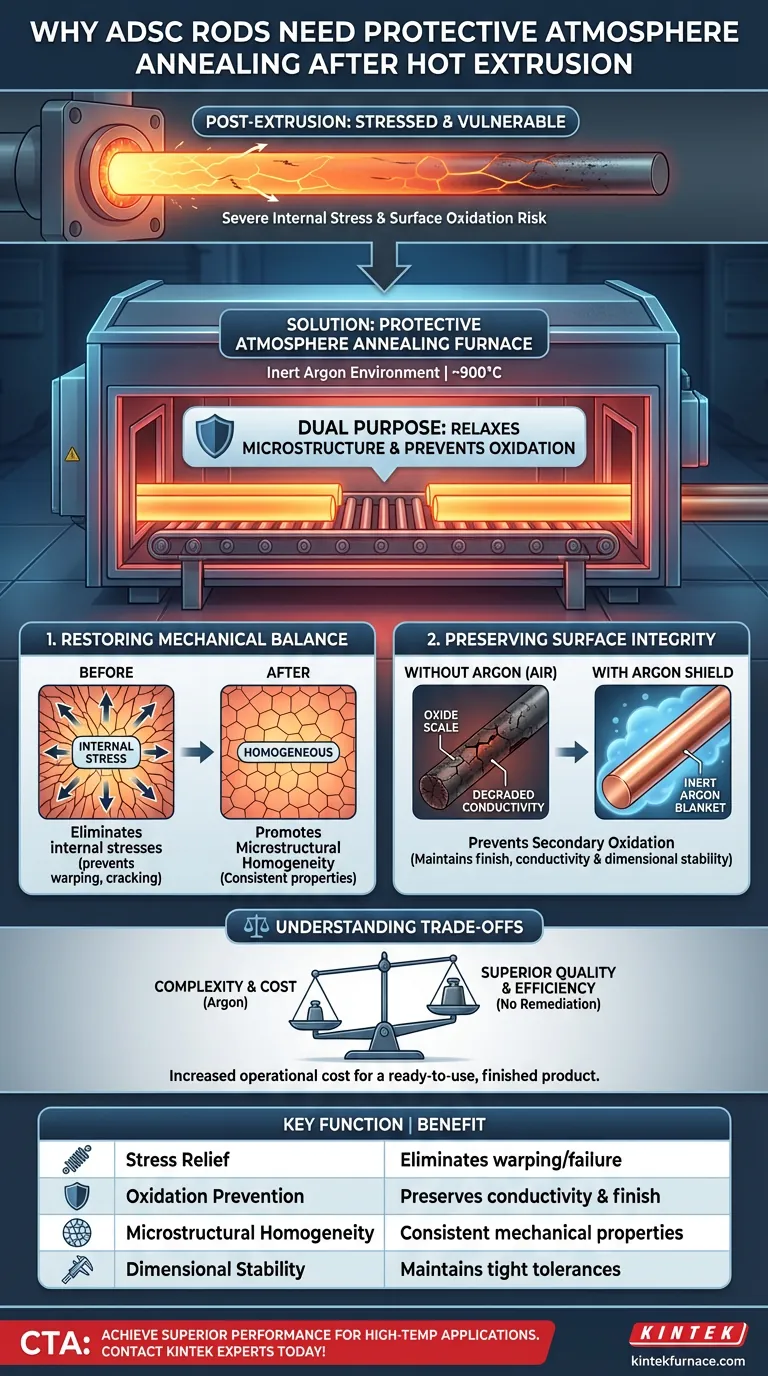

The post-extrusion phase is as critical as the forming process itself. A protective atmosphere annealing furnace is required to treat Alumina Dispersion Strengthened Copper (ADSC) rods to eliminate severe internal stresses caused by hot extrusion while strictly preventing surface oxidation. By maintaining an inert argon environment at approximately 900°C, this equipment restores the material's mechanical balance without compromising its surface integrity.

The hot extrusion process forces metal into shape but leaves it structurally strained and vulnerable. The protective atmosphere annealing furnace serves a dual purpose: it relaxes the material's microstructure to ensure consistent performance and uses an inert gas shield to guarantee the rod remains oxidation-free and dimensionally accurate.

Restoring Mechanical Balance

After the physical violence of hot extrusion, the copper matrix is chemically stable but mechanically chaotic. The annealing process is necessary to reset the material's internal structure.

Eliminating Internal Stress

Hot extrusion involves forcing metal through a die under extreme pressure, which generates significant internal stresses within the rod.

If left untreated, these residual stresses can lead to warping, cracking, or premature failure during service.

Annealing at temperatures around 900°C provides the thermal energy required to relax the lattice structure and release this stored tension.

Promoting Microstructural Homogeneity

The extrusion process can result in an uneven grain structure across the length and cross-section of the rod.

The annealing furnace promotes microstructural homogeneity, ensuring the grains are uniform.

This uniformity is essential for achieving consistent mechanical properties, such as ductility and conductivity, throughout the entire batch.

Preserving Surface Integrity

While heat is necessary for stress relief, heat in the presence of oxygen is detrimental to copper. The "protective atmosphere" component of the furnace is the solution to this contradiction.

Preventing Secondary Oxidation

At 900°C, copper is highly reactive to oxygen in standard air.

Exposure to air at these temperatures would cause rapid "secondary oxidation," creating a brittle oxide scale on the rod's surface.

This scaling would degrade the material's electrical conductivity and ruin its surface finish.

The Role of Argon Shielding

To counter oxidation, the furnace utilizes an argon environment.

Argon is an inert gas that displaces oxygen, effectively blanketing the ADSC rods during the heating cycle.

This protection ensures the material emerges from the furnace with its original surface quality intact, ready for subsequent high-temperature applications.

Understanding the Trade-offs

While protective atmosphere annealing is the superior method for treating ADSC rods, it introduces specific operational considerations that must be managed.

Complexity vs. Quality

Using an argon atmosphere adds complexity and cost compared to standard air annealing.

However, skipping this protection invariably leads to material loss through surface scaling and cleaning requirements.

The trade-off is an increased operational cost in exchange for a "finished" product that requires no further surface remediation.

Dimensional Stability

Annealing can sometimes induce slight dimensional changes as stresses are relieved.

However, the protective atmosphere prevents the formation of oxide layers that would physically alter the rod's dimensions.

Therefore, while stress relief relaxes the metal, the argon environment ensures dimensional stability is maintained within tight tolerances.

Making the Right Choice for Your Goal

The necessity of this equipment depends on the specific quality metrics you are prioritizing for your final component.

- If your primary focus is Long-Term Reliability: The furnace is essential to eliminate internal stresses that would otherwise cause the part to distort or crack under thermal load.

- If your primary focus is Manufacturing Efficiency: The argon environment prevents oxidation, eliminating the need for post-annealing pickling or surface grinding steps.

Proper annealing transforms an extruded shape into an engineering-grade component.

Summary Table:

| Key Function | Benefit for ADSC Rods |

|---|---|

| Stress Relief | Eliminates internal stresses from hot extrusion, preventing warping and failure. |

| Oxidation Prevention | Argon atmosphere prevents surface scaling, preserving conductivity and finish. |

| Microstructural Homogeneity | Promotes uniform grain structure for consistent mechanical properties. |

| Dimensional Stability | Maintains tight tolerances by preventing oxide-induced dimensional changes. |

Achieve superior material performance for your high-temperature applications. The precise control required for treating advanced materials like ADSC is exactly what we specialize in. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, including custom protective atmosphere furnaces designed for your unique material processing needs. Contact our experts today to discuss how a KINTEK furnace can enhance your lab's efficiency and product quality.

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the key features of calcining furnaces? Boost Efficiency and Quality in Material Processing

- Why must the carbonization of coffee-based bio-adsorbents be performed in a nitrogen furnace? Expert Guide

- What gases are introduced into the box type annealing atmosphere furnace? Optimize Your Heat Treatment Process

- How does a high-temperature electric furnace facilitate the sintering process of 3Y-TZP ceramics? Master Densification

- Why is a nitrogen environment necessary for Cu13Se52Bi35 thin film annealing? Protect Your Material Purity

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- How does a lamp furnace integrated with a tensile testing machine function? Expert High-Temp Shear Strength Analysis

- What industries commonly use controlled atmosphere furnaces? Unlock Precision in High-Tech Manufacturing