At their core, controlled atmosphere furnaces are mission-critical tools across a surprisingly diverse set of high-tech industries. The most common users include metallurgy, electronics and semiconductor manufacturing, ceramics, aerospace, and chemical processing, as well as materials science research in academic and government labs.

The fundamental value of a controlled atmosphere furnace is not merely the generation of heat, but the precise control over the chemical environment during heating. This allows industries to transform materials in ways that would be impossible in open air, either by preventing unwanted reactions like oxidation or by intentionally inducing specific ones.

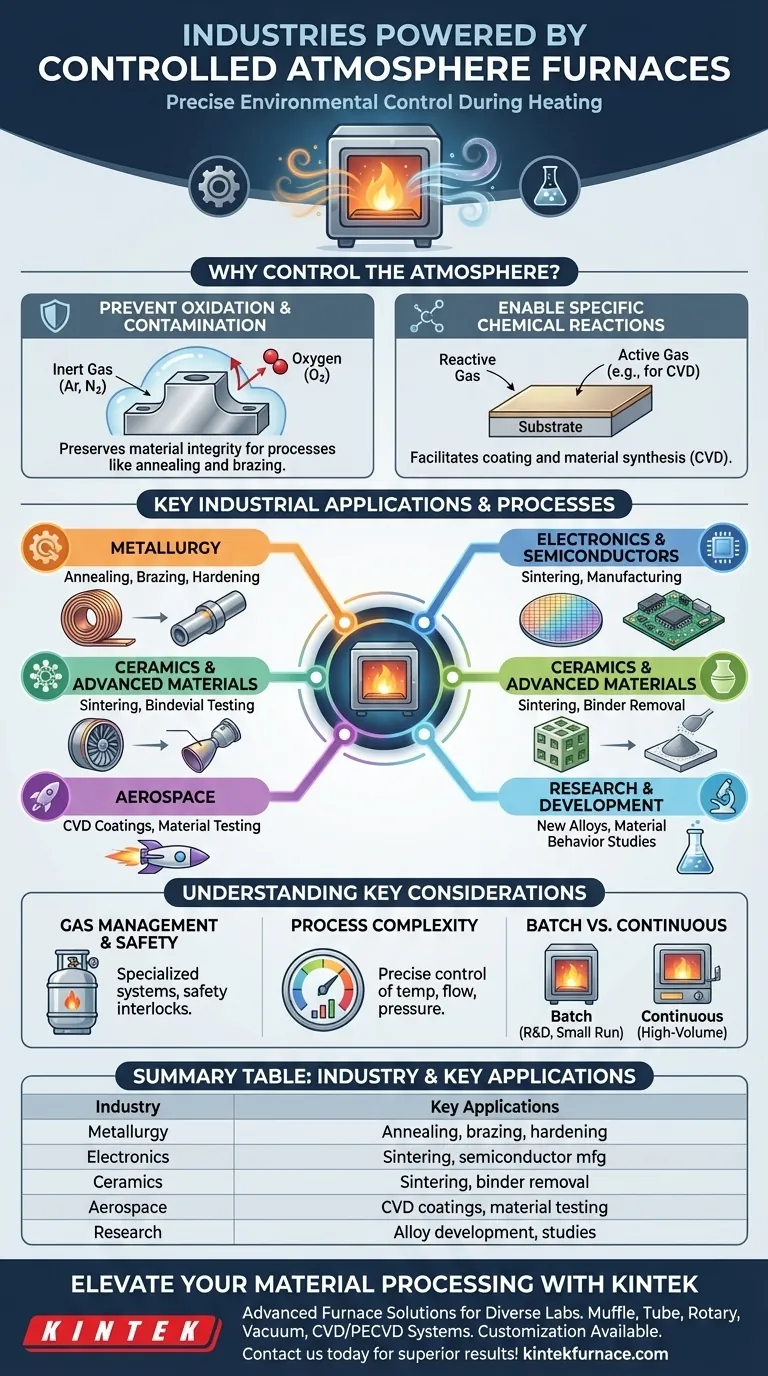

The Core Principle: Why Control the Atmosphere?

The function of these furnaces goes far beyond simple heating. They create a sealed environment where the standard air is replaced with a specific gas or vacuum to dictate the outcome of a thermal process.

Preventing Oxidation and Contamination

At high temperatures, most metals and many advanced materials react readily with the oxygen in the air. This reaction, known as oxidation, can weaken parts, ruin electronic properties, or cause components to fail.

A controlled atmosphere furnace purges the oxygen and replaces it with an inert gas like argon or nitrogen, creating a neutral environment. This ensures the material's integrity is preserved during processes like annealing or brazing.

Enabling Specific Chemical Reactions

In some applications, the atmosphere is not inert but chemically active. The gas is deliberately chosen to react with the material's surface in a controlled way.

A key example is Chemical Vapor Deposition (CVD), where gases decompose at high temperatures to deposit a thin, high-performance film onto a substrate. This is fundamental to making semiconductors and aerospace coatings.

A Breakdown of Key Industrial Applications

The need to control chemical reactions at high temperatures is the common thread that connects many advanced manufacturing sectors.

Metallurgy and Metal Processing

This is one of the largest applications. Furnaces are used for annealing (softening metals to improve workability), brazing (joining parts, especially aluminum in the automotive industry), and hardening specialized tool steels.

Electronics and Semiconductors

The manufacturing of microchips, solar cells, and optical components demands extreme purity. Controlled atmospheres prevent microscopic contamination that could ruin a device's function.

Processes like sintering electronic components and creating pure crystalline structures rely entirely on these furnaces.

Ceramics, Glass, and Advanced Materials

Sintering is the process of heating powdered materials until their particles bond together, forming a solid object without fully melting. This is how high-strength ceramics are made.

A controlled atmosphere ensures that binders used in the "green" ceramic part are burned away cleanly and that the final material has the desired density and strength.

Research and Development

Nearly every materials science lab has a controlled atmosphere furnace. It is an indispensable tool for developing new alloys, ceramics, and polymers, and for testing how materials behave under extreme conditions.

Understanding the Key Considerations

While powerful, these systems are more complex than simple ovens and involve important operational trade-offs.

Gas Management and Safety

The gases used—such as hydrogen, nitrogen, and argon—require specialized storage, piping, and safety systems. Furnaces must have robust safety interlocks to prevent gas leaks or dangerous pressure buildups, ensuring a safe work environment.

Process Complexity

Achieving a repeatable, high-quality result depends on precise control over temperature profiles, gas flow rates, and pressure. These are not "set and forget" devices; they require skilled operators and careful process development.

Batch vs. Continuous Processing

Furnaces come in two main configurations. Batch furnaces (like box furnaces) are ideal for R&D, small production runs, or treating individual, high-value parts.

Continuous furnaces (like conveyor belt furnaces) are designed for high-volume manufacturing, where parts move steadily through different temperature and atmosphere zones. This is common in the automotive and electronics industries.

Making the Right Choice for Your Goal

Selecting the right furnace configuration depends entirely on the intended application and scale of production.

- If your primary focus is high-volume manufacturing: A continuous furnace designed for a specific process like brazing or annealing will provide the greatest efficiency.

- If your primary focus is high-purity material synthesis: Prioritize a furnace with high-vacuum capability and systems designed for ultra-pure gas handling, common in semiconductor and aerospace applications.

- If your primary focus is general heat treatment: A versatile batch furnace with options for multiple inert and active gases offers the most flexibility for treating various metals and parts.

- If your primary focus is research and development: A smaller, flexible box-type atmosphere furnace is the most cost-effective and adaptable tool for experimenting with new materials and processes.

By understanding the underlying purpose of atmospheric control, you can effectively choose and apply this technology to achieve your material processing objectives.

Summary Table:

| Industry | Key Applications |

|---|---|

| Metallurgy | Annealing, brazing, hardening |

| Electronics | Sintering, semiconductor manufacturing |

| Ceramics | Sintering, binder removal |

| Aerospace | CVD coatings, material testing |

| Research | Alloy development, material behavior studies |

Ready to elevate your material processing with precision? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in metallurgy, electronics, or aerospace, we can help you achieve superior results. Contact us today to discuss your needs and discover how our solutions can benefit your operations!

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- Why are inert atmosphere furnaces important for graphite and carbon products? Prevent Oxidation and Ensure High-Performance Results

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance