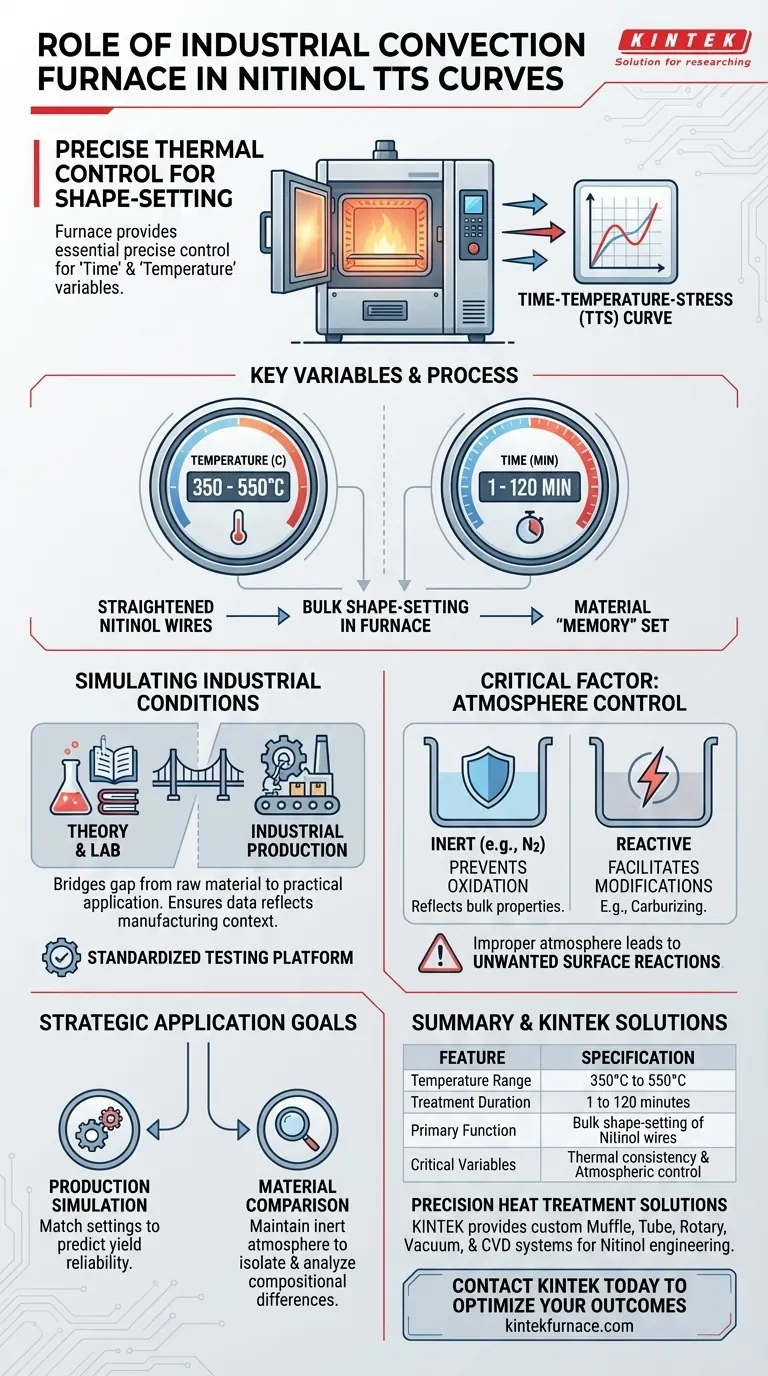

The role of an industrial convection air furnace is to provide the precise thermal control required to define the "Time" and "Temperature" variables essential for constructing Time-Temperature-Stress (TTS) curves. Specifically, the furnace is used for the bulk shape-setting and heat treatment of straightened Nitinol wires, allowing researchers to simulate industrial processing conditions within a temperature range of 350 to 550°C and durations spanning 1 to 120 minutes.

By simulating industrial shape-memory setting environments, the convection furnace bridges the gap between raw material theory and practical application. It provides a standardized thermal platform, ensuring that the resulting TTS curves accurately reflect how different Nitinol compositions will respond mechanically in a manufacturing context.

Establishing a Standardized Testing Platform

Simulating Industrial Conditions

To construct meaningful TTS curves, you cannot rely on theoretical thermal data; you must replicate the actual environment the material will face during manufacturing.

The industrial convection air furnace simulates these industrial shape-memory setting environments. This ensures that the data collected is not just academic, but directly applicable to production processes.

Precise Thermal Parameters

The furnace offers a broad yet controlled operating window essential for mapping the material's behavior.

It accommodates heat treatment durations ranging from 1 to 120 minutes.

Simultaneously, it maintains critical temperature setpoints between 350 and 550°C, covering the standard range required for Nitinol shape setting.

The Mechanics of Material Response

Bulk Shape-Setting

The primary function of the furnace in this context is the bulk treatment of straightened Nitinol wires.

This process sets the "memory" of the material, defining the baseline shape to which the alloy will attempt to return.

Analyzing Mechanical Variations

Once the thermal history is established by the furnace, the material can be stressed to generate the final TTS curve.

This platform allows engineers to analyze differences in the mechanical response across various Nitinol compositions. By keeping the thermal variables constant and controlled, any variance in the TTS curve can be attributed to the material composition itself.

Understanding the Trade-offs

The Impact of Atmosphere

While the primary reference focuses on thermal control, the furnace atmosphere is a critical variable that can alter your results.

An improper atmosphere can lead to unwanted surface reactions, such as oxidation, which may skew the mechanical data of the wire.

Inert vs. Reactive Environments

Depending on the specific furnace configuration, the atmosphere can be adjusted to either protect or modify the material.

A chemically inert atmosphere is often used to prevent oxidation, ensuring the TTS curve reflects the bulk material properties rather than surface defects. Conversely, a reactive atmosphere may be used if the goal is to facilitate specific surface modifications like carburizing.

Making the Right Choice for Your Goal

To maximize the utility of an industrial convection furnace for TTS curve construction, align your settings with your specific engineering objectives:

- If your primary focus is Production Simulation: Match the furnace temperature and duration (350-550°C, 1-120 min) exactly to your intended manufacturing specifications to predict yield reliability.

- If your primary focus is Material Comparison: Maintain a strictly inert atmosphere and identical thermal cycles to isolate and analyze the mechanical differences between varying Nitinol compositions.

Reliable TTS curves depend not just on measuring stress, but on the absolute consistency of the thermal history provided by your furnace.

Summary Table:

| Feature | Specification/Role |

|---|---|

| Temperature Range | 350°C to 550°C |

| Treatment Duration | 1 to 120 minutes |

| Primary Function | Bulk shape-setting of Nitinol wires |

| Data Application | Simulating industrial manufacturing environments |

| Critical Variables | Thermal consistency and atmospheric control |

Precision Heat Treatment for Nitinol Engineering

To construct reliable Time-Temperature-Stress (TTS) curves, you need absolute thermal consistency and specialized equipment. KINTEK provides industry-leading solutions backed by expert R&D and advanced manufacturing. Our range of Muffle, Tube, Rotary, Vacuum, and CVD systems are fully customizable to meet the unique thermal demands of Nitinol shape-setting and materials research.

Ensure your data integrity with high-performance lab furnaces designed for precision. Contact KINTEK today to discuss your unique needs and see how our expertise can optimize your production and research outcomes.

Visual Guide

References

- Scott W. Robertson, Eric Veit. Nitinol Post-Shape-Setting Time Temperature Transformation (TTT) and Time Temperature Stress (TTS) Properties. DOI: 10.1007/s40830-025-00541-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the purpose of a chemically inert atmosphere in a furnace? Protect Materials from Oxidation & Contamination

- What is the function of a high-temperature calcination furnace? Mastering Pr3+:CaGdF2 Nanopowder Precursor Prep

- What are the primary industrial applications of atmosphere furnaces? Essential for High-Temp Material Processing

- How do temperature control and uniformity compare between box furnaces and atmosphere furnaces? Achieve Precision and Consistency

- Why is an air furnace used with boron nitride powder for copper? Achieve Oxidation-Free Heat Treatment

- What is a vacuum atmosphere furnace? Master High-Purity Heat Treatment for Superior Materials

- What is the function of an atmosphere tube furnace in activated carbon treatment? Precision Thermal Control

- Why is continuous argon flow essential for biochar pyrolysis? Unlock High-Yield, High-Purity Results