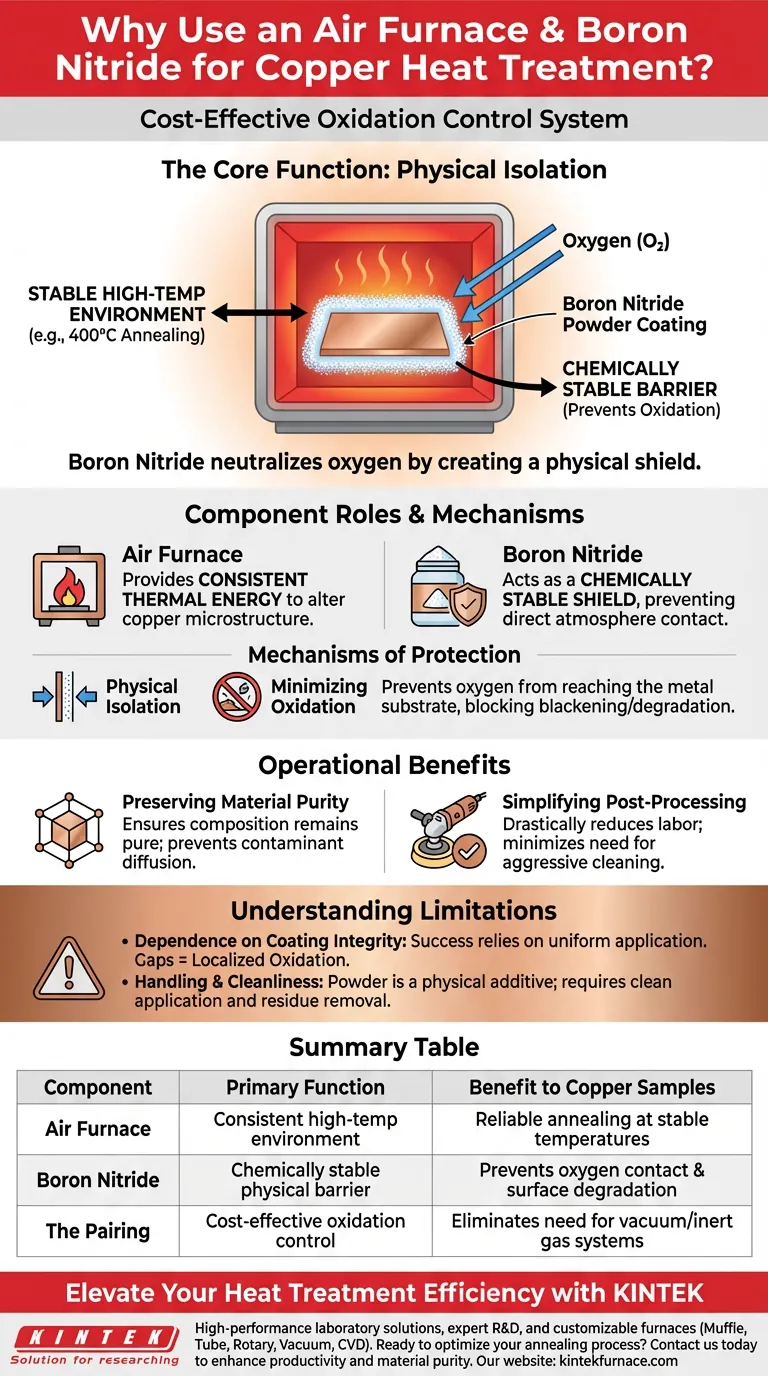

The combination of an air furnace and boron nitride powder creates a cost-effective system for heat treating copper without oxidation. The air furnace provides the necessary stable high-temperature environment (typically around 400°C) required for annealing. Simultaneously, the boron nitride powder serves as a protective physical barrier, allowing the copper to be heated in regular air without suffering from the surface degradation that usually occurs in oxygen-rich environments.

The core function of this pairing is physical isolation within a reactive environment. Boron nitride neutralizes the primary downside of an air furnace—the presence of oxygen—by coating the copper in a chemically stable layer that prevents direct contact with the atmosphere.

The Roles of the Components

The Function of the Air Furnace

The air furnace is utilized primarily to provide a stable high-temperature environment.

It maintains the consistent thermal energy required to alter the microstructure of the copper, such as during a 400°C annealing process.

The Protective Barrier of Boron Nitride

Boron nitride powder is applied as a coating directly onto the copper surface.

Because it is chemically stable, it does not react with the copper even at elevated temperatures.

Mechanisms of Protection

Preventing Physical Contact

The fundamental mechanism at work here is physical isolation.

The powder layer acts as a shield, creating a boundary between the metal substrate and the furnace atmosphere.

Minimizing High-Temperature Oxidation

Copper is highly susceptible to oxidation when heated in the presence of air.

By preventing oxygen from directly contacting the metal substrate, the boron nitride coating effectively blocks the oxidation reaction that would otherwise blacken or degrade the copper surface.

Operational Benefits

Preserving Material Purity

The isolation provided by the powder ensures the composition of the material remains pure.

It prevents external contaminants from the air from diffusing into the copper lattice during the heating cycle.

Simplifying Post-Processing

Using this method significantly reduces the labor required after heat treatment.

Because oxidation is minimized, the need for aggressive surface polishing or chemical cleaning steps is drastically simplified.

Understanding the Limitations

Dependence on Coating Integrity

The success of this method relies entirely on the uniformity of the boron nitride application.

If the powder coating is inconsistent or has gaps, oxygen will penetrate those areas, leading to localized oxidation spots on the sample.

Handling and Cleanliness

While chemically stable, the powder is a physical additive that must be managed.

Users must ensure the powder is applied cleanly and that the physical residue is removed appropriately after the process to avoid interfering with subsequent manufacturing steps.

Making the Right Choice for Your Process

If you are evaluating heat treatment methods for copper, consider your specific constraints.

- If your primary focus is process simplicity: Use this method to utilize standard air furnaces without the expense or complexity of vacuum or inert gas systems.

- If your primary focus is surface quality: Rely on the boron nitride barrier to minimize oxidation, thereby preserving the material's purity and reducing post-anneal polishing time.

This approach effectively bridges the gap between high-temperature requirements and the need for surface protection.

Summary Table:

| Component | Primary Function | Benefit to Copper Samples |

|---|---|---|

| Air Furnace | Consistent high-temperature environment | Reliable annealing at stable temperatures (e.g., 400°C) |

| Boron Nitride | Chemically stable physical barrier | Prevents oxygen contact and surface degradation |

| The Pairing | Cost-effective oxidation control | Eliminates the need for expensive vacuum or inert gas systems |

Elevate Your Heat Treatment Efficiency with KINTEK

Don't let surface oxidation compromise your research or production. KINTEK provides high-performance laboratory solutions backed by expert R&D and manufacturing. Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temp furnaces are fully customizable to meet your unique materials science requirements.

Ready to optimize your annealing process? Contact us today to discover how our precision equipment can enhance your lab's productivity and material purity.

Visual Guide

References

- Daniel Shtuckmeyster, Roni Z. Shneck. The Influence of Crystal Orientation and Thermal State of a Pure Cu on the Formation of Helium Blisters. DOI: 10.3390/met14030260

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of a hydrogenation furnace in U-6Nb powder production? Master Chemical Embrittlement

- How does a continuous controlled atmosphere furnace operate? Unlock High-Volume Precision in Material Processing

- What is the significance of a controlled atmosphere in a retort furnace? Ensure Purity and Precision in Thermal Processing

- What types of gases are used in inert ovens to create a controlled environment? Discover Nitrogen vs. Argon for Optimal Results

- What are the performance requirements for a laboratory oven used in heat tinting ADI? Achieve Thermal Precision

- What is the primary role of the furnace atmosphere in material processing? Control Chemical Reactions for Superior Results

- What are the operational considerations for atmosphere furnaces? Master Precise Control for Safe, Efficient Results

- What is the role of a benchtop drying oven in the preparation of Cu/TiO2/ZSM-5 catalysts? Ensure Optimal Dispersion