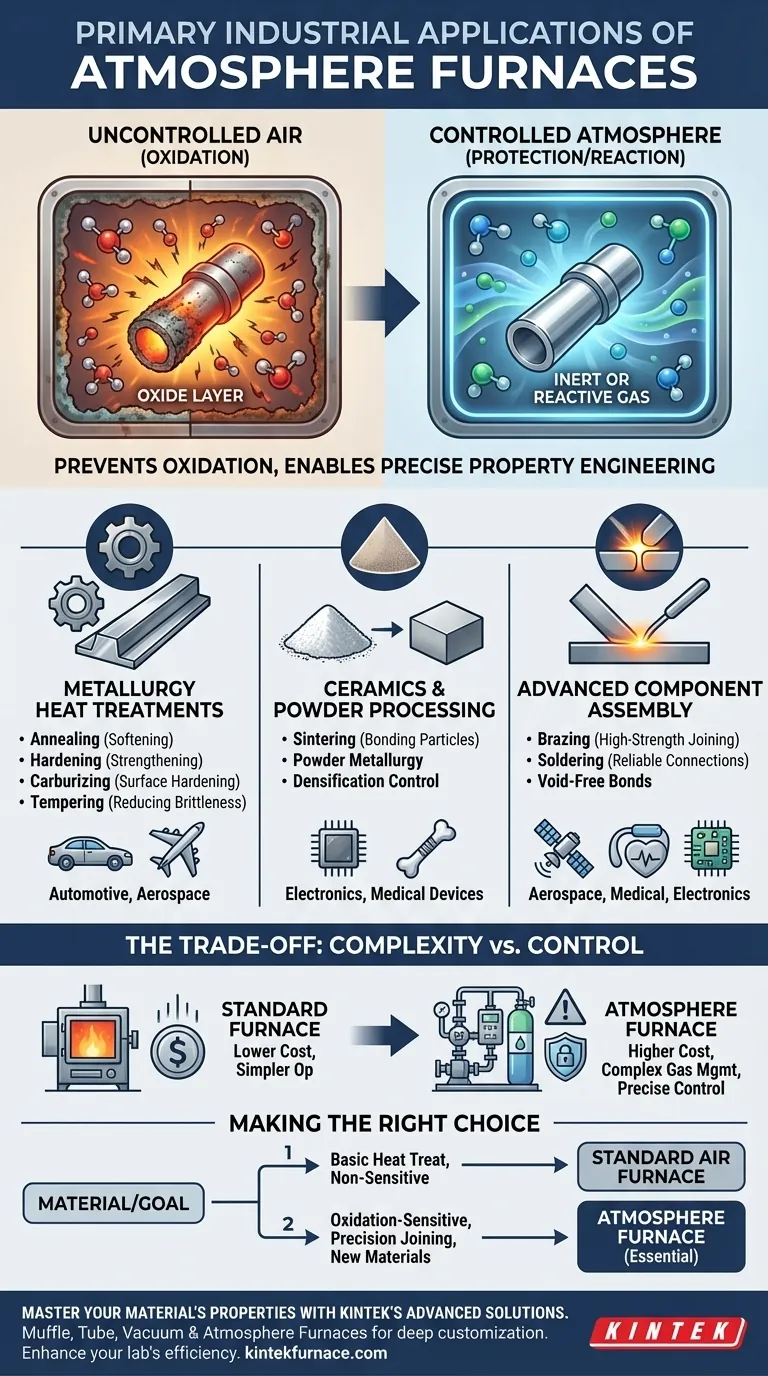

At their core, atmosphere furnaces are used across major industries for any high-temperature process where the material’s properties would be compromised by reacting with the open air. Their primary applications are found in metallurgy for heat treatments like annealing and hardening, in ceramics for sintering, and in electronics manufacturing for high-purity brazing and soldering. These furnaces are critical in sectors like aerospace, automotive, and medical device manufacturing where material integrity is non-negotiable.

The fundamental purpose of an atmosphere furnace is not just to apply heat, but to control the chemical environment during heating. This control prevents destructive reactions like oxidation and enables the precise engineering of a material's final properties.

The Core Problem: Why a Controlled Atmosphere is Necessary

The need for an atmosphere furnace arises from a simple chemical fact: when most materials get hot, they become highly reactive with the oxygen and moisture present in the air.

The Enemy of Heat Treatment: Oxidation

At elevated temperatures, oxygen aggressively bonds with the surface of metals, forming a brittle, discolored layer of oxide scale.

This oxidation is rarely desirable. It ruins the surface finish, can alter the dimensions of a precision part, and creates a weak outer layer that compromises the material's structural integrity.

The Solution: Replacing Air with a Purposeful Gas

An atmosphere furnace solves this by first purging the ambient air from the heating chamber, often with a low vacuum or by flushing it with an inert gas.

The chamber is then filled with a carefully selected gas or gas mixture—the "atmosphere"—that serves a specific purpose for the duration of the heating and cooling cycle.

Types of Atmospheres and Their Roles

The chosen atmosphere dictates the outcome. Inert atmospheres, using gases like argon or nitrogen, are purely protective and prevent any chemical reaction from occurring.

Reactive atmospheres, such as those using hydrogen or dissociated ammonia, are used to actively clean the part's surface by reducing existing oxides. Others, like endothermic gas, can be used for processes like carburizing, where carbon is intentionally added to the surface of steel to harden it.

Key Industrial Applications by Process

While the industries are diverse, the core processes that rely on atmosphere furnaces are consistent and highly specialized.

Metallurgical Heat Treatments

This is the most common application domain. Processes like annealing (softening metal for forming), hardening (strengthening steel), and tempering (reducing brittleness) all require precise temperature control without surface oxidation.

Specialty processes like carburizing would be impossible without a controlled atmosphere to precisely introduce carbon into the steel's surface.

Ceramic and Powder Material Processing

Sintering is a process where fine powders (ceramic or metallic) are heated below their melting point until their particles bond together, forming a solid, dense object.

An atmosphere furnace is essential for sintering because it prevents oxidation of metal powders and can control the rate of densification, which is critical for achieving the desired mechanical and electrical properties in components like magnets or semiconductor substrates.

Advanced Component Assembly

Brazing and soldering are processes used to join materials together using a filler metal. For high-reliability applications in aerospace, electronics, or medical devices, these joints must be perfectly clean and strong.

Using an atmosphere furnace (often with a hydrogen or vacuum atmosphere) ensures that no oxides can form on the joint surfaces, allowing the filler metal to flow cleanly and create a void-free, high-strength bond.

Understanding the Trade-offs

While powerful, atmosphere furnaces introduce complexity and cost that are not always necessary.

Cost and Complexity vs. Standard Furnaces

An atmosphere furnace is significantly more complex than a standard air furnace. The sealed chamber, vacuum pumps, gas delivery systems, and safety interlocks add considerable upfront cost and maintenance requirements.

Gas Management and Safety

Handling industrial gases, especially flammable ones like hydrogen, requires rigorous safety protocols, leak detection systems, and proper ventilation. The ongoing cost of these gases must also be factored into operational budgets.

Process Control and Repeatability

The main advantage of an atmosphere furnace is also a source of complexity. Achieving a truly pure and consistent atmosphere requires precise control over gas flow rates, chamber pressure, and purge cycles. Any failure in this system can ruin an entire batch of expensive parts.

Making the Right Choice for Your Goal

The decision to use an atmosphere furnace should be driven entirely by the material you are processing and the properties you need to achieve.

- If your primary focus is basic heat treatment of non-sensitive metals: A standard air furnace is often sufficient and more cost-effective.

- If you are processing oxidation-sensitive materials (e.g., titanium, tool steels, aluminum): An atmosphere furnace is essential to protect the material's surface and integrity.

- If you need to join dissimilar materials with high precision (e.g., electronics, medical devices): Atmosphere brazing is the industry standard for creating clean, strong, and reliable joints.

- If you are developing new materials or working with metal powders: The precise environmental control of an atmosphere furnace is non-negotiable for research and powder metallurgy.

Ultimately, mastering your material's properties begins with mastering its chemical environment during heat treatment.

Summary Table:

| Application Area | Key Processes | Industries Benefited |

|---|---|---|

| Metallurgy | Annealing, Hardening, Carburizing | Automotive, Aerospace |

| Ceramics & Powders | Sintering | Electronics, Medical Devices |

| Component Assembly | Brazing, Soldering | Aerospace, Medical, Electronics |

Master your material's properties with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for oxidation control, sintering, or brazing. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments