In simple terms, a vacuum atmosphere furnace is a specialized oven that first uses a vacuum to remove all the air and other unwanted gases from its chamber. After creating this ultra-clean environment, it can then perform a heat treatment process either in that vacuum or after backfilling the chamber with a specific, controlled gas like nitrogen or argon.

The core purpose of a vacuum atmosphere furnace is not just to heat a material, but to gain absolute control over the chemical environment during that heating process. By first removing reactive gases like oxygen, it prevents contamination and enables superior material processing.

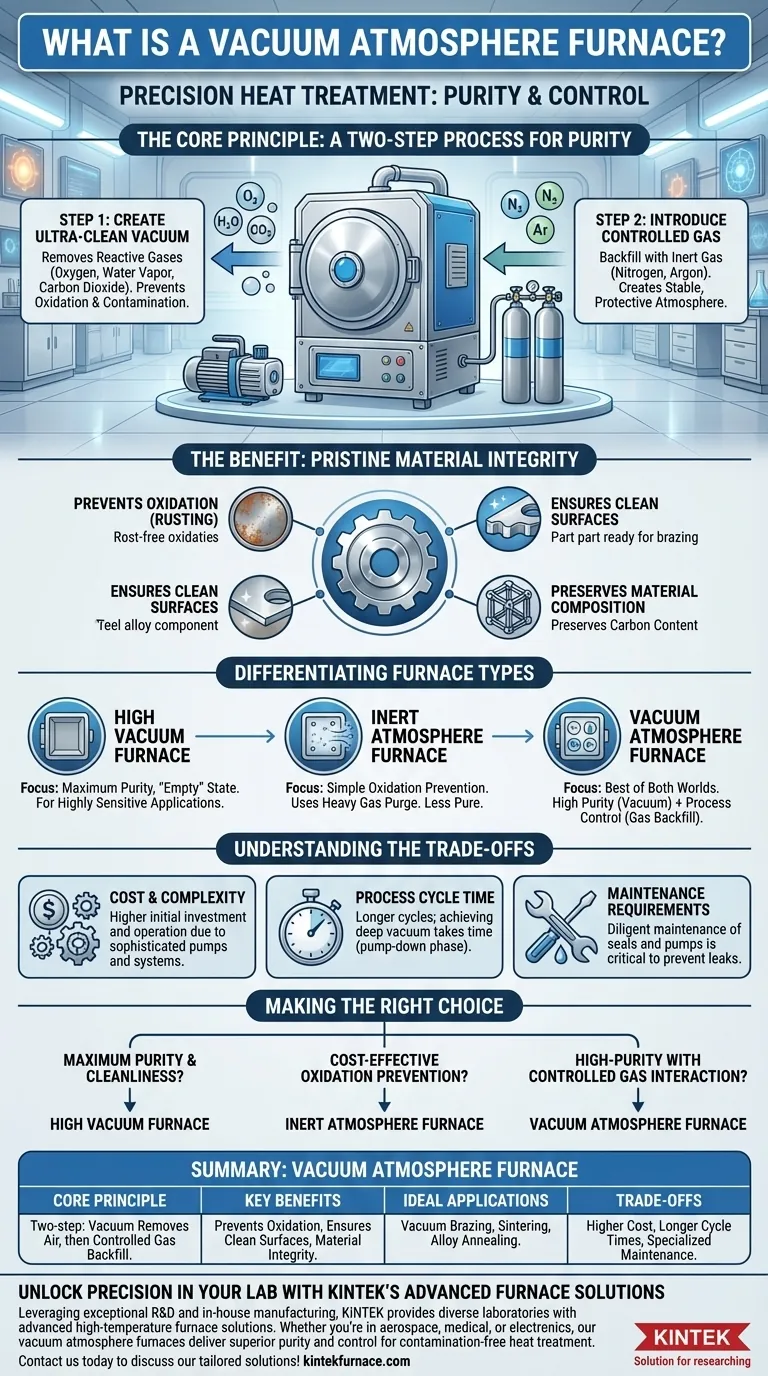

The Core Principle: Achieving Purity and Control

A vacuum atmosphere furnace operates on a two-step principle that ensures the highest level of environmental control during high-temperature processing. This control is essential for modern materials engineering.

Step 1: Removing the Unwanted Atmosphere

The first and most critical step is creating a vacuum. A powerful pump system removes the air, and with it, reactive gases like oxygen, water vapor, and carbon dioxide.

This process is fundamental because these ambient gases can cause undesirable chemical reactions at high temperatures, such as oxidation (rusting), decarburization (carbon loss), and general surface contamination.

Step 2: Introducing the Desired Atmosphere

Once a clean, empty environment is established, the process has two main paths. It can proceed in a high vacuum, which is essentially an inert environment, or the chamber can be backfilled with a specific gas.

This backfilling is what defines the "atmosphere" part of the name. By introducing a pure, non-reactive gas like argon or nitrogen, engineers can create a precise and stable atmosphere that protects the material without the side effects of air.

The Benefit: Pristine Material Integrity

The result of this meticulous control is the ability to heat-treat parts without degrading their surface or chemical composition.

This prevents unwanted oxides from forming, ensures clean surfaces for processes like brazing, and preserves the precise carbon content in steel alloys, leading to stronger, more reliable, and higher-quality components.

Differentiating Furnace Types

The term "vacuum atmosphere" can be confusing because it overlaps with other furnace technologies. Understanding the differences is key to choosing the right tool.

High Vacuum Furnace

A true high vacuum furnace focuses solely on removing as much atmosphere as possible. Its goal is to operate in the purest "empty" state achievable.

These are used for the most sensitive applications where the mere presence of any gas molecules, even inert ones, could interfere with the process.

Inert Atmosphere Furnace

This type of furnace doesn't necessarily use a deep vacuum. Instead, it purges the chamber by flooding it with a heavy inert gas (like argon) to push the lighter air out.

It is a simpler and often faster method for preventing oxidation, but it is less pure than a vacuum-purged system, as trace amounts of air may remain.

Vacuum Atmosphere Furnace

This furnace represents a hybrid approach. It uses vacuum technology for its superior purification capability to remove virtually all air and moisture.

It then leverages the benefits of a controlled inert gas backfill to stabilize pressure and ensure perfect atmospheric chemistry, offering the best of both worlds: exceptional purity and precise process control.

Understanding the Trade-offs

While powerful, vacuum atmosphere technology is not always the necessary choice. Its advantages come with practical considerations.

Cost and Complexity

Vacuum systems involve sophisticated pumps, seals, valves, and gauges. This makes these furnaces significantly more expensive to purchase and operate than simpler inert gas or air furnaces.

Process Cycle Time

Achieving a deep vacuum is not instantaneous. The "pump-down" phase can add considerable time to the overall heat treatment cycle, which can impact production throughput.

Maintenance Requirements

The integrity of the vacuum is critical. Seals, pumps, and sensors require diligent, specialized maintenance to prevent leaks and ensure the system performs to specification. Even a tiny leak can compromise the entire process.

Making the Right Choice for Your Process

Selecting the correct furnace technology depends entirely on the material requirements and the desired outcome.

- If your primary focus is maximum purity and cleanliness: A dedicated high vacuum furnace is the correct tool, especially for aerospace, medical, or electronic components.

- If your primary focus is preventing basic oxidation cost-effectively: A standard inert atmosphere furnace that purges with argon or nitrogen is often sufficient and more economical.

- If your primary focus is high-purity processing with controlled gas interaction: The vacuum atmosphere furnace is ideal for demanding processes like vacuum brazing, sintering, and advanced alloy annealing where initial purity is critical.

Ultimately, mastering heat treatment is about mastering the environment in which it occurs.

Summary Table:

| Feature | Description |

|---|---|

| Core Principle | Two-step process: vacuum removes air, then controlled gas backfill for purity. |

| Key Benefits | Prevents oxidation, decarburization; ensures clean surfaces and material integrity. |

| Ideal Applications | Vacuum brazing, sintering, alloy annealing in aerospace, medical, and electronics. |

| Trade-offs | Higher cost, longer cycle times, and specialized maintenance requirements. |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in aerospace, medical, or electronics, our vacuum atmosphere furnaces deliver superior purity and control for contamination-free heat treatment.

Contact us today to discuss how our tailored solutions can enhance your material processing and drive innovation in your projects!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation