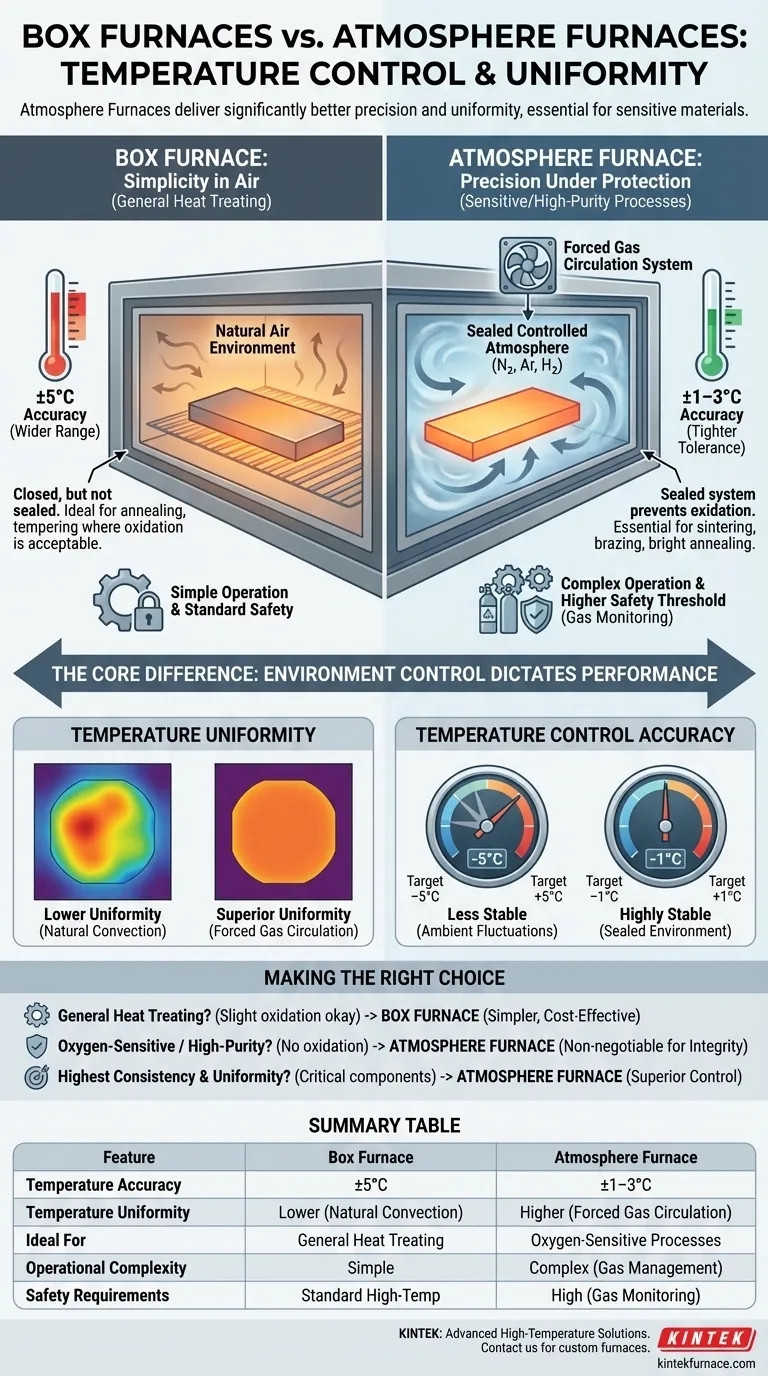

In short, atmosphere furnaces provide significantly better temperature control and uniformity than box furnaces. An atmosphere furnace typically maintains a temperature accuracy of ±1–3°C, while a standard box furnace operates within a wider range of ±5°C. This superior performance is due to the sealed design and gas circulation systems inherent to atmosphere furnaces.

The choice between a box furnace and an atmosphere furnace is fundamentally a choice about process environment. The superior temperature control of an atmosphere furnace is a direct consequence of its primary function: replacing ambient air with a controlled gas to protect materials from oxidation.

The Core Difference: Environment Control

The primary distinction between these two furnaces is not their heating method, but the environment in which the material is heated. This single factor dictates their capabilities, complexity, and temperature performance.

Box Furnaces: Simplicity in Air

A box furnace operates in a natural air environment. Its chamber is closed but not sealed against atmospheric gases.

This makes them ideal for conventional heat-treating processes like annealing, tempering, and drying, where exposure to oxygen is not a critical concern or is an intended part of the process.

Atmosphere Furnaces: Precision Under Protection

An atmosphere furnace is a sealed system that allows you to introduce a specific, controlled gas like nitrogen, argon, or hydrogen.

This controlled atmosphere is essential for preventing oxidation when processing sensitive metals. It also enables specialized surface treatments like carburization or sintering, where the gas composition must be precisely managed.

How Environment Dictates Temperature Performance

The difference in atmospheric control directly impacts temperature uniformity and accuracy. A sealed, controlled system is inherently more stable and predictable than an open one.

Temperature Uniformity

Atmosphere furnaces use gas circulation systems, often involving fans, to actively move the inert gas throughout the chamber. This forced convection ensures heat is distributed far more evenly than the natural convection currents found in a standard box furnace.

The result is superior temperature uniformity across the entire workpiece, leading to more consistent material properties and performance.

Temperature Control Accuracy

The sealed chamber of an atmosphere furnace creates a highly stable thermal environment. The control system, which uses thermocouples to monitor and adjust heating elements, doesn't have to fight fluctuations from ambient air drafts or changing humidity.

This stability allows the furnace to maintain a much tighter temperature tolerance (±1–3°C), which is critical for processes with a narrow window for success. A box furnace's less-controlled environment naturally leads to wider temperature swings (±5°C).

Understanding the Trade-offs: Simplicity vs. Capability

While an atmosphere furnace offers superior performance, that capability comes with significant trade-offs in complexity and safety.

Operational Complexity

A box furnace is comparatively simple to operate, often requiring little more than setting the temperature and time. Its safety requirements are focused on standard high-temperature protection.

An atmosphere furnace is a far more complex system. It requires managing gas supplies, flow rates, and pressures, along with sophisticated monitoring to ensure the atmosphere remains pure. This demands professionally trained operators.

Safety and Infrastructure

The use of inert, flammable, or even explosive gases (like hydrogen) means atmosphere furnaces have a much higher safety threshold. They necessitate gas monitoring systems, leak detectors, and often explosion-proof devices to ensure safe operation.

Making the Right Choice for Your Process

Your decision should be based entirely on the requirements of your material and process.

- If your primary focus is general heat treating (tempering, drying, pre-heating) where slight oxidation is acceptable: A box furnace is the simpler and more cost-effective choice.

- If your primary focus is processing oxygen-sensitive materials or requiring high-purity results (sintering, brazing, bright annealing): An atmosphere furnace is non-negotiable to prevent oxidation and ensure material integrity.

- If your primary focus is achieving the highest possible consistency and uniformity for critical components: The superior control and forced gas circulation of an atmosphere furnace make it the clear winner.

Ultimately, the right furnace is the one that creates the precise environment your material needs to achieve its target properties.

Summary Table:

| Feature | Box Furnace | Atmosphere Furnace |

|---|---|---|

| Temperature Accuracy | ±5°C | ±1–3°C |

| Temperature Uniformity | Lower (natural convection) | Higher (forced gas circulation) |

| Ideal For | General heat treating (e.g., annealing, tempering) | Oxygen-sensitive processes (e.g., sintering, brazing) |

| Operational Complexity | Simple | Complex (requires gas management) |

| Safety Requirements | Standard high-temperature protection | High (gas monitoring, leak detectors) |

Need a furnace that delivers precise temperature control and uniformity for your lab? KINTEK specializes in advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental requirements. Contact us today to discuss how our furnaces can enhance your process efficiency and material outcomes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance