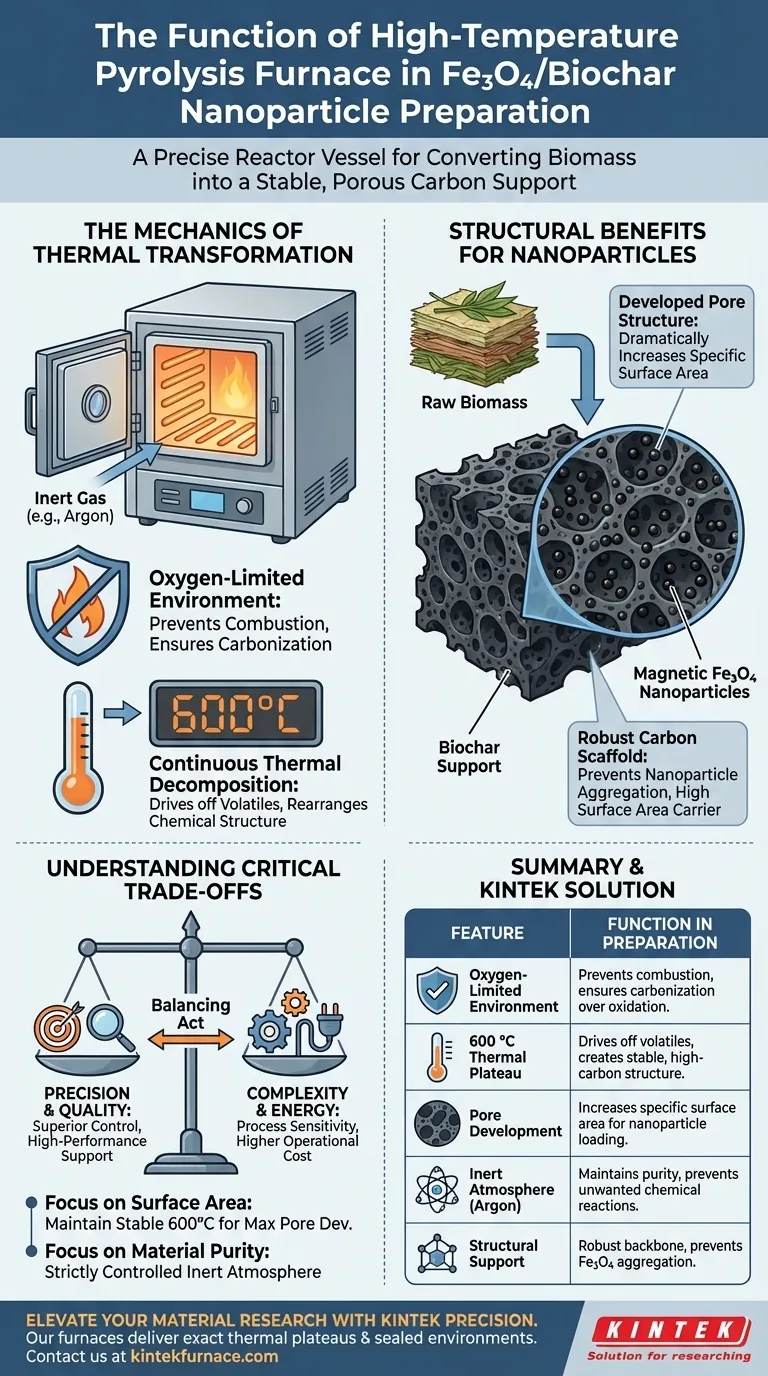

The high-temperature pyrolysis furnace functions as a precise reactor vessel that facilitates the thermal conversion of raw biomass into a stable, porous carbon support structure. It provides a strictly controlled, oxygen-limited environment heated to 600 °C, which is necessary to decompose biomass into biochar without burning it to ash.

The core value of this furnace lies in its ability to maintain a continuous, sealed thermal environment. This transforms raw biological material into a high-carbon, high-surface-area scaffold essential for supporting and stabilizing magnetic Fe3O4 nanoparticles.

The Mechanics of Thermal Transformation

Creating an Oxygen-Limited Environment

The primary function of the furnace is to create a sealed environment that restricts oxygen ingress.

Unlike a standard oven, which might allow combustion, this furnace ensures the material undergoes pyrolysis (chemical decomposition by heat) rather than burning. This is often achieved using a protective atmosphere, such as argon, to ensure reduction and carbonization occur rather than oxidation.

Continuous Thermal Decomposition

The furnace executes a continuous thermal decomposition process, specifically targeting a temperature of 600 °C.

At this specific thermal plateau, volatile components of the biomass are driven off. The remaining material rearranges chemically, transitioning from complex organic biological structures into stable carbon structures.

Structural Benefits for Nanoparticles

Developing a Support Architecture

The intense heat of the furnace creates a developed pore structure within the resulting biochar.

This porosity is not merely a byproduct; it is the functional goal. These pores create a vast internal network, dramatically increasing the specific surface area available for chemical interactions.

The Role of the Carbon Scaffold

The process yields a material with high carbon content, turning the biomass into a robust carrier.

This carbon backbone serves as a high specific surface area support. This support is critical for the subsequent loading of Fe3O4 nanoparticles, preventing them from aggregating and ensuring they are distributed evenly across the material.

Understanding the Critical Trade-offs

Precision vs. Complexity

While a high-temperature furnace offers superior control, it introduces significant process sensitivity.

The heating program must be precise. Deviations from the target 600 °C or failures in the atmospheric seal can lead to incomplete carbonization or unwanted oxidation, compromising the magnetic properties of the final composite.

Energy Intensity

This method requires substantial energy to maintain high temperatures for extended periods.

While it produces a superior high-quality support compared to low-temperature methods, the operational cost is higher. You are trading energy efficiency for the structural integrity and surface area required for high-performance applications.

Making the Right Choice for Your Goal

To maximize the effectiveness of your pyrolysis process, align your furnace parameters with your specific material requirements:

- If your primary focus is Surface Area: Prioritize maintaining a stable 600 °C temperature to maximize pore development without collapsing the carbon structure.

- If your primary focus is Material Purity: Ensure the furnace utilizes a strictly controlled inert atmosphere (like argon) to prevent oxidation during the carbonization phase.

The high-temperature pyrolysis furnace is the bridge between raw biological waste and advanced functional materials, turning simple biomass into a sophisticated nanostructure support.

Summary Table:

| Feature | Function in Nanoparticle Preparation |

|---|---|

| Oxygen-Limited Environment | Prevents combustion and ensures carbonization over oxidation. |

| 600 °C Thermal Plateau | Drives off volatiles to create a stable, high-carbon structure. |

| Pore Development | Increases specific surface area for nanoparticle loading and distribution. |

| Inert Atmosphere (Argon) | Maintains material purity and prevents unwanted chemical reactions. |

| Structural Support | Provides a robust backbone to prevent Fe3O4 nanoparticle aggregation. |

Elevate Your Material Research with KINTEK Precision

Precision is non-negotiable when synthesizing high-performance magnetic nanoparticles. KINTEK provides industry-leading high-temperature furnaces designed to deliver the exact thermal plateaus and sealed environments required for superior biochar production.

Why choose KINTEK?

- Expert R&D & Manufacturing: Our systems are engineered for the rigorous demands of advanced carbonization and chemical vapor deposition.

- Versatile Solutions: From Muffle and Tube furnaces to Rotary and Vacuum systems, we cover every lab and industrial need.

- Fully Customizable: We tailor our high-temp systems to your specific atmosphere and temperature requirements, ensuring consistent, high-quality yields.

Ready to transform your biomass into advanced functional supports? Contact KINTEK today to consult with our experts on the perfect furnace for your unique research goals.

Visual Guide

References

- Biomass-Derived Magnetic Fe3O4/Biochar Nanoparticles from Baobab Seeds for Sustainable Wastewater Dye Remediation. DOI: 10.3390/ijms26178499

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the two main types of atmosphere furnaces based on design? Choose the Right Furnace for Your Lab

- Why Use a Nitrogen Debinding Furnace for 17-4PH? Ensure Pure Metal Bonds & Prevent Oxidation

- What are the main purposes of using an inert atmosphere? Prevent Oxidation and Ensure Process Safety

- What types of gases are used in controlled atmosphere furnaces? Optimize Material Protection and Transformation

- What is the function of a controlled atmosphere in Violet Phosphorus research? Achieve High-Purity Material Restoration

- Why must Boron Nitride Spheres with binders undergo heat treatment in air? Unlock Maximum Thermal Conductivity

- What are the advantages of controlled atmosphere furnaces over the older types? Boost Efficiency, Quality, and Safety

- What industries commonly use low vacuum atmosphere furnaces? Key Sectors for Cost-Effective Heat Treatment