In short, low vacuum atmosphere furnaces are commonly used in the automotive, tool manufacturing, metallurgy, and ceramics industries. They are essential for processes like the brazing of aluminum parts, sintering of metal powders, and the general heat treatment of materials that require a controlled environment but are not extremely sensitive to oxidation.

A low vacuum atmosphere furnace strikes a critical balance between performance and cost. It provides a cleaner environment than an open-air furnace by removing most oxygen, but avoids the high expense and complexity of a high-vacuum system, making it the workhorse for many industrial applications.

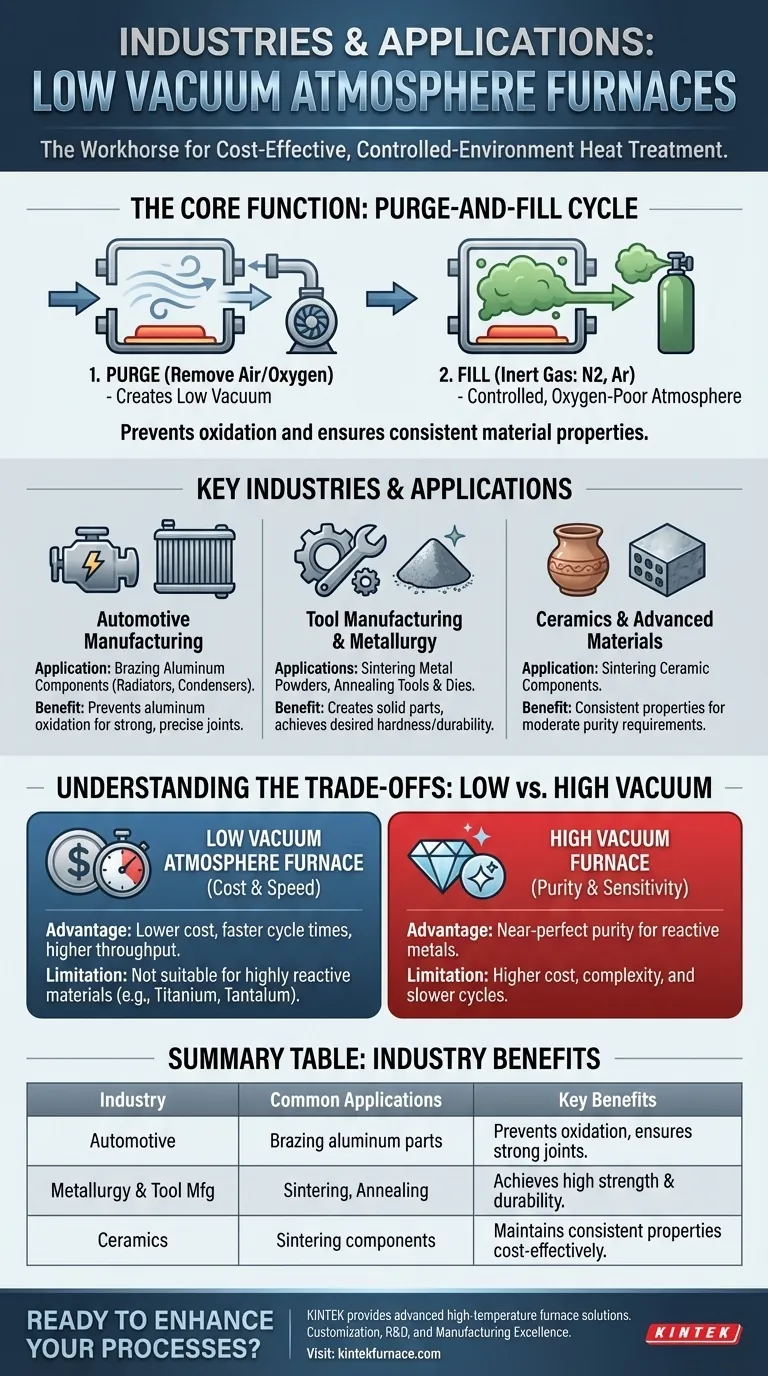

The Core Function: Creating a Controlled Environment

A low vacuum atmosphere furnace doesn't operate in a vacuum. Instead, it uses a vacuum pump for a crucial first step: purging.

The Purge-and-Fill Cycle

The furnace chamber is sealed and a vacuum pump removes the ambient air, which is rich in reactive oxygen. This is the "low vacuum" stage.

Once the air is removed, the chamber is backfilled with a non-reactive, inert gas like nitrogen or argon. This creates a controlled, oxygen-poor atmosphere that protects the material during high-temperature processing.

Why This Matters

This process prevents unwanted chemical reactions, primarily oxidation (rusting or scaling), and other forms of contamination. It ensures the material's properties remain consistent and the final product meets its engineering specifications.

A Closer Look at Key Industries and Applications

The cost-effectiveness and reliability of these furnaces make them staples in several key sectors for specific, high-volume processes.

Automotive Manufacturing

This is a primary user, especially for brazing aluminum components. Parts like radiators, condensers, and other heat exchangers are joined together precisely in these furnaces. The controlled atmosphere prevents the aluminum from oxidizing, which would weaken the brazed joints.

Metallurgy and Tool Manufacturing

In metallurgy, these furnaces are used for sintering. This process takes metal powders and fuses them under heat and pressure to create solid, high-strength components without melting them.

For tool manufacturing, annealing (softening and relieving stress) and other heat treatments are performed in controlled atmospheres to achieve the desired hardness and durability in tools and dies.

Ceramics and Advanced Materials

The ceramics industry uses these furnaces for sintering parts where moderate purity is sufficient. It allows for the production of advanced ceramic components with consistent properties without the need for a more expensive high-vacuum environment.

Understanding the Trade-offs: Low Vacuum vs. High Vacuum

Choosing the right furnace type is a critical engineering decision driven by material properties and budget.

The Advantage: Cost and Speed

Low vacuum atmosphere furnaces are significantly less expensive to build and operate than their high-vacuum counterparts. Their pump-down cycles are much faster, leading to higher throughput for industrial production.

Maintenance is also simpler, as the systems are less complex and operate under less extreme conditions.

The Limitation: Material Sensitivity

The primary limitation is purity. A low vacuum purge cycle does not remove 100% of the reactive gases.

This makes these furnaces unsuitable for highly reactive materials like titanium, tantalum, or certain advanced superalloys. These materials require the near-perfect void of a high-vacuum furnace to prevent even trace amounts of oxygen from causing embrittlement or contamination.

Selecting the Right Furnace for Your Application

Your choice depends entirely on your material's sensitivity and your production goals.

- If your primary focus is cost-effective production of common metals or ceramics: A low vacuum atmosphere furnace is almost always the correct and most economical choice.

- If your primary focus is joining non-ferrous parts like aluminum heat exchangers: Low vacuum brazing is the proven industry standard for this application.

- If your primary focus is processing highly reactive or oxygen-sensitive materials: You must invest in a high-vacuum furnace to guarantee the required purity and material integrity.

Ultimately, understanding the trade-off between atmospheric purity and operational cost empowers you to make the most effective choice for your project.

Summary Table:

| Industry | Common Applications | Key Benefits |

|---|---|---|

| Automotive | Brazing aluminum parts (e.g., radiators) | Prevents oxidation, ensures strong joints |

| Metallurgy & Tool Manufacturing | Sintering metal powders, annealing tools | Achieves high strength and durability |

| Ceramics | Sintering ceramic components | Maintains consistent properties cost-effectively |

Ready to enhance your industrial processes with reliable, cost-effective furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs. Contact us today to discuss how our solutions can optimize your heat treatment applications and drive efficiency in your operations!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity