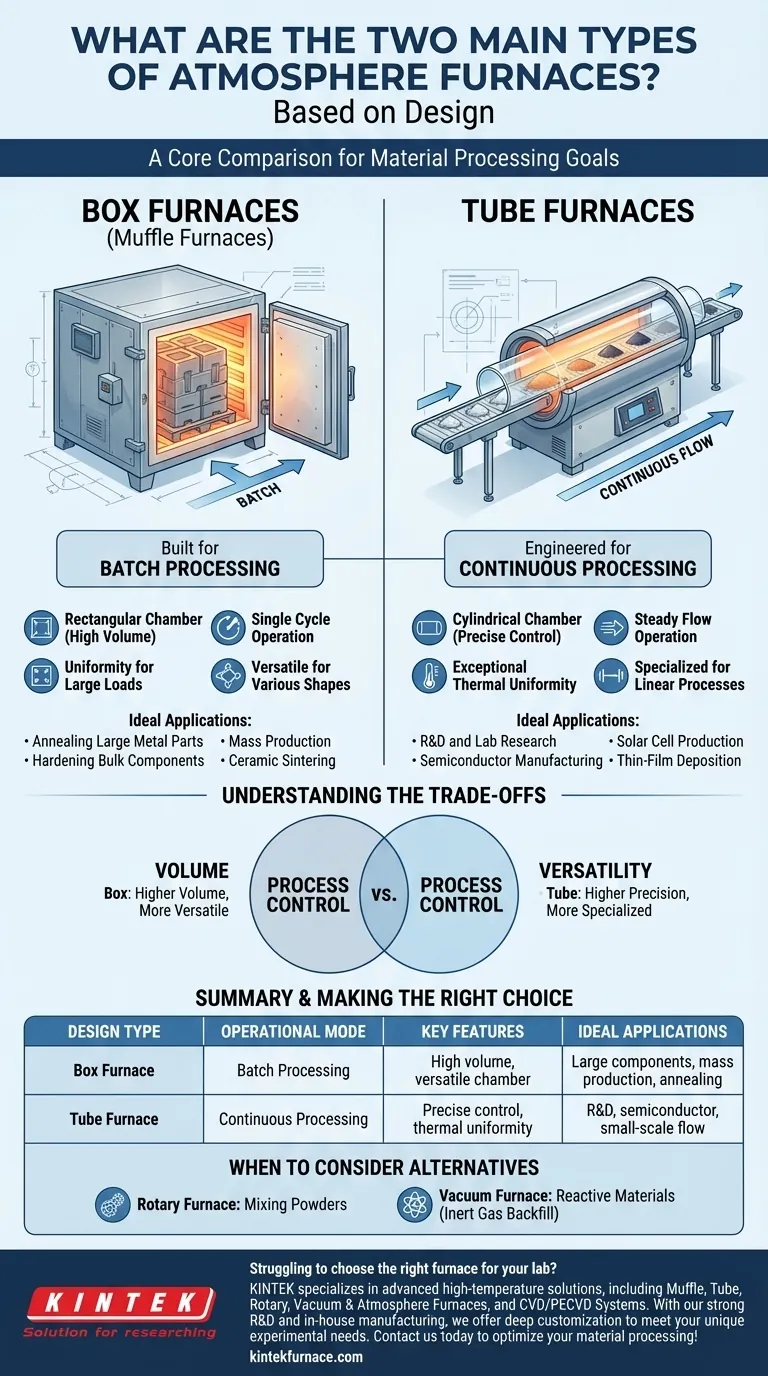

At their core, atmosphere furnaces are categorized into two primary designs based on their physical structure and processing method. The two most common types are box furnaces, which use a rectangular chamber for processing materials in batches, and tube furnaces, which use a cylindrical chamber ideal for continuous flow or small-scale sample processing.

The choice between a box and a tube furnace is fundamentally a decision between batch processing for scale and continuous processing for precision. Understanding this distinction is the key to selecting the right tool for your material processing goal.

Dissecting the Core Designs

The physical shape of a furnace directly dictates its ideal use case, influencing everything from sample volume to process type.

The Box Furnace: Built for Batch Processing

A box furnace, also known as a muffle furnace, features a rectangular chamber. Its primary function is to process a set quantity of material, or "batch," in a single cycle.

You load the materials, seal the chamber, run the heating and atmosphere control cycle, and then unload the finished product. This design is ideal for processing large, bulky components or large quantities of smaller parts simultaneously.

The Tube Furnace: Engineered for Continuous Flow

A tube furnace uses a cylindrical tube, typically made of ceramic or quartz, as its heating chamber. Materials are passed through the tube, allowing for a continuous or semi-continuous process.

This design excels in laboratory settings, research and development, and small-scale production where precise control over a moving sample is required. It is common in applications like semiconductor manufacturing and solar cell production.

Operational Mode: Batch vs. Continuous

While design is the physical blueprint, the operational mode is the functional strategy. This is the most critical distinction for aligning a furnace with your application.

Understanding Batch Processing

Batch processing is the go-to method for treatments like annealing or hardening large metal parts. The entire workload is heated and cooled together, making it suitable for mass production where uniformity across a single load is key. Box furnaces are the standard for this mode.

Understanding Continuous Processing

Continuous processing involves materials moving steadily through the furnace's controlled environment. This is essential for processes that require a consistent, repeatable thermal gradient. Tube furnaces are the quintessential continuous design, but other specialized types like rotary furnaces (for tumbling and mixing materials) also fit this category.

Understanding the Trade-offs

No single design is universally superior. The optimal choice depends on balancing volume, precision, and flexibility.

Volume vs. Process Control

Box furnaces offer significantly higher processing volume per cycle. However, maintaining a perfectly uniform temperature and atmosphere across a large, three-dimensional chamber can be more challenging than in the constrained environment of a tube furnace.

Tube furnaces provide exceptional process control and thermal uniformity but are limited to smaller sample sizes and lower throughput.

Versatility vs. Specialization

Box furnaces are generally more versatile, accommodating a wide variety of part sizes and shapes. Their simple, open design makes them a flexible workhorse for many metallurgical and ceramic applications.

Tube furnaces are more specialized. They are perfected for linear processes, thin-film deposition, and experiments where a sample must move through different temperature zones in a highly controlled manner.

When Neither Design Is Perfect

For highly sensitive materials requiring extremely low pressure, a vacuum furnace backfilled with an inert gas is often necessary. These systems provide the cleanest possible environment by first removing reactive gases before introducing a controlled atmosphere.

Making the Right Choice for Your Application

To select the correct furnace, start by defining your primary processing objective.

- If your primary focus is mass production or heat-treating large components: A box furnace offers the necessary capacity and batch-processing capability.

- If your primary focus is research, development, or small-scale continuous flow: A tube furnace provides the precision and controlled environment you need.

- If your primary focus is processing powders or granulars that require constant mixing: A rotary furnace is the most effective design.

- If your primary focus is processing highly reactive or oxygen-sensitive materials: A vacuum furnace with inert gas backfilling is the definitive choice for purity.

Ultimately, aligning the furnace's design and operational mode with your specific material and end-goal is the only path to a successful outcome.

Summary Table:

| Design Type | Operational Mode | Key Features | Ideal Applications |

|---|---|---|---|

| Box Furnace | Batch Processing | High volume, versatile chamber | Large components, mass production, annealing |

| Tube Furnace | Continuous Processing | Precise control, thermal uniformity | R&D, semiconductor, small-scale flow |

Struggling to choose the right furnace for your lab? KINTEK specializes in advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to optimize your material processing!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments