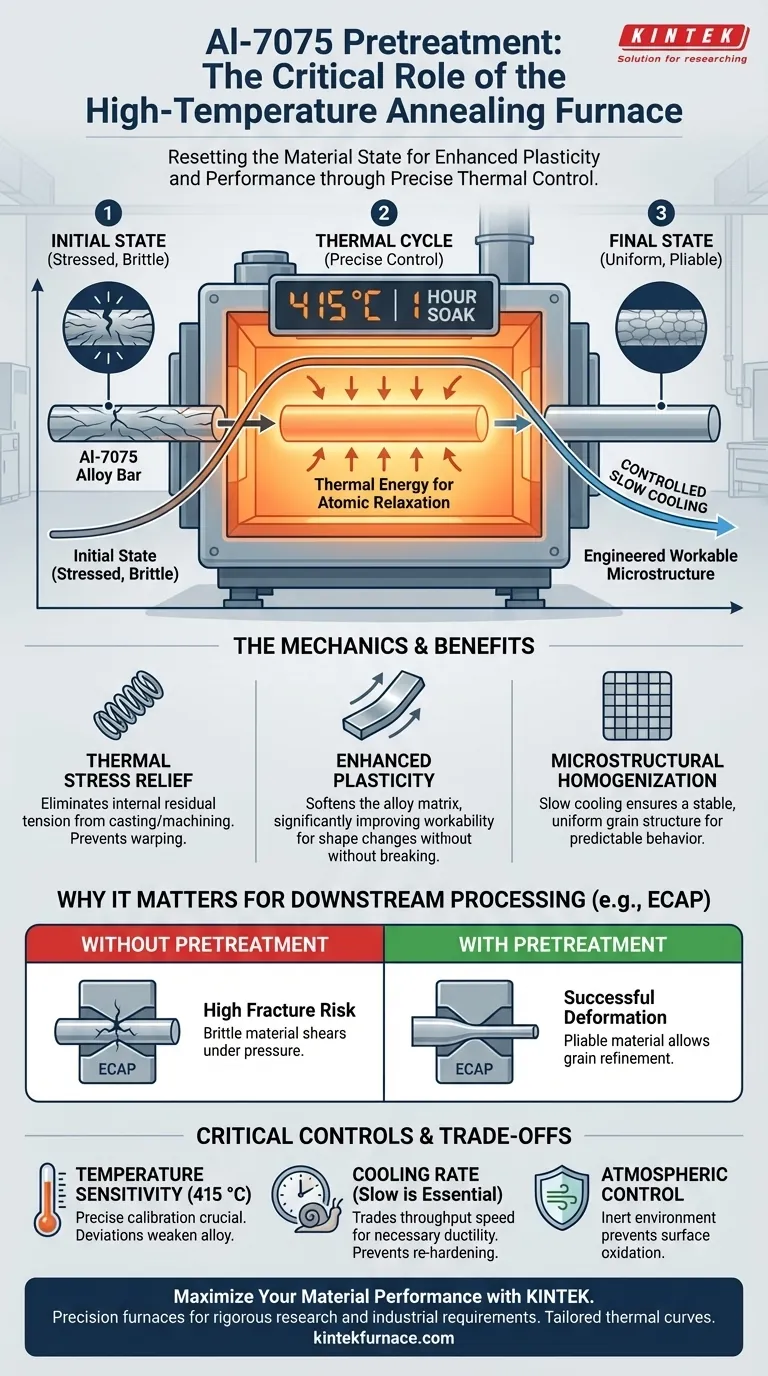

The primary function of a high-temperature annealing furnace in the pretreatment of Al-7075 alloy bars is to reset the material's internal physical state through precise thermal control.

Specifically, the furnace maintains the alloy at 415 °C for one hour, followed by a controlled slow cooling process. This thermal cycle eliminates internal residual stresses accumulated during prior manufacturing and significantly improves the alloy's plasticity, making it softer and more pliable.

Core Takeaway The annealing furnace does not merely heat the metal; it engineers a uniform and workable initial microstructure. This step is essential to prevent fracture during subsequent severe plastic deformation processes, such as Equal Channel Angular Pressing (ECAP).

The Mechanics of the Pretreatment Process

Thermal Stress Relief

Al-7075 bars often carry internal tension from casting or previous mechanical work.

The furnace holds the material at 415 °C to provide the thermal energy required for atomic relaxation. This effectively neutralizes these residual stresses, preventing warping or cracking during future machining.

Enhancing Plasticity

For high-strength alloys like Al-7075, workability is a major challenge.

By soaking the material at high heat, the furnace softens the alloy matrix. This improvement in plasticity is critical for allowing the material to undergo shape changes without breaking.

Controlled Microstructural Homogenization

The "slow cooling" phase mentioned in the primary reference is just as critical as the heating phase.

Cooling the bars slowly within the furnace ensures the microstructure remains uniform and stable. Rapid cooling would lock in new stresses or alter the grain structure unfavorably, negating the benefits of the heat treatment.

Why This Matters for Downstream Processing

Enabling Severe Plastic Deformation

The primary reference highlights that this pretreatment is a prerequisite for Equal Channel Angular Pressing (ECAP).

ECAP involves forcing the material through extreme angles to refine grain size. Without the plasticity gained from the annealing furnace, Al-7075—which is naturally brittle in certain tempers—would likely shear or fracture under this pressure.

Ensuring Process Consistency

A uniform microstructure leads to predictable behavior.

By standardizing the grain structure in the furnace, engineers ensure that every bar responds identically to physical force. This consistency is vital for accurate experimentation and reliable mass production.

Understanding the Trade-offs and Critical Controls

Precision vs. Throughput

The requirement for slow cooling within the furnace creates a bottleneck in production speed.

While accelerating the cooling process would increase throughput, it risks re-hardening the material or inducing thermal shock. You trade processing speed for necessary material ductility.

Temperature Sensitivity

The specific target of 415 °C is calibrated for Al-7075.

Deviating from this temperature can be detrimental. Too low, and the stresses are not fully relieved; too high, and you risk excessive grain growth or incipient melting of grain boundaries, which weakens the alloy.

Atmospheric Control

While the primary focus is thermal, the furnace environment matters.

As noted in broader metallurgical contexts, high temperatures can lead to surface oxidation. Although Al-7075 is robust, neglecting the furnace atmosphere (e.g., lacking inert gas shielding) can degrade surface quality, requiring additional cleanup steps later.

Making the Right Choice for Your Goal

When configuring your pretreatment protocols for Al-7075, align your furnace parameters with your specific end-goals.

- If your primary focus is enabling severe deformation (ECAP): Prioritize the slow cooling phase above all else to maximize plasticity and minimize the risk of fracture during pressing.

- If your primary focus is stress relief for machining: Ensure the hold time of one hour at 415 °C is strictly observed to fully relax the internal lattice structure.

Success in processing Al-7075 relies not just on reaching the right temperature, but on the precise control of the cooling curve that follows.

Summary Table:

| Process Phase | Parameter | Primary Function |

|---|---|---|

| Soaking/Heating | 415 °C for 1 Hour | Relieves internal residual stresses and neutralizes atomic tension. |

| Cooling Phase | Controlled Slow Cooling | Ensures microstructural uniformity and prevents re-hardening or cracking. |

| Material Outcome | Enhanced Plasticity | Softens the alloy matrix to enable fracture-free deformation (e.g., ECAP). |

| Structural Goal | Homogenization | Creates a stable, uniform grain structure for consistent downstream processing. |

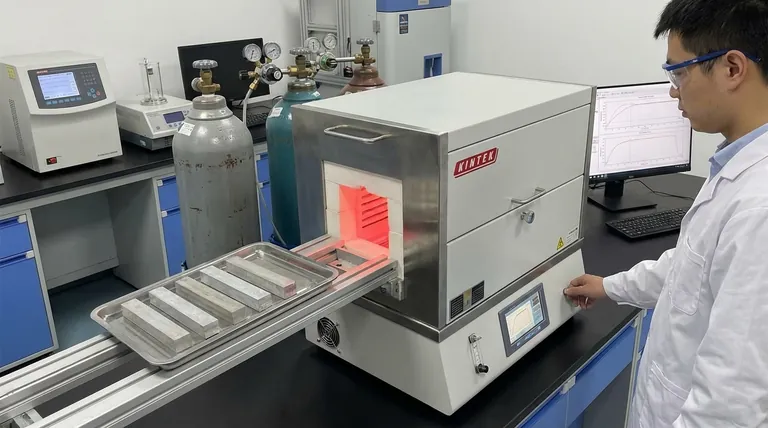

Maximize Your Material Performance with KINTEK

Precision is non-negotiable when heat-treating high-strength alloys like Al-7075. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for rigorous laboratory and industrial requirements.

Whether you need to refine grain structures via ECAP or ensure uniform stress relief, our customizable high-temperature furnaces deliver the exact thermal curves your research demands.

Ready to elevate your metallurgy workflow? Contact KINTEK today for a customized solution!

Visual Guide

References

- Qussay Salah Mahdi, Mustafa Mohammed Abdulrazaq. [RETRACTED] An Investigation of the Equal Channel Angular Pressing Process on the Hardness of Heat-Treated Al-7075 Alloy. DOI: 10.48084/etasr.10911

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the requirements for high-pressure applications in an atmosphere box furnace? Essential Guide to Safe Pressure Vessel Systems

- How is a controlled atmosphere furnace used in material research? Achieve Precise Material Synthesis and Heat Treatment

- What effects does a reducing atmosphere have on ceramic wares during firing? Unlock Deep Colors and Unique Finishes

- What are the advantages of controlled atmosphere furnaces over the older types? Boost Efficiency, Quality, and Safety

- Why is a high-purity argon atmosphere critical for successful molten salt electrochemical testing? Expert Guide

- What is the function of a retort furnace? Achieve Precise Atmosphere Control for Material Processing

- Why are Argon and Hydrogen utilized as the process atmosphere during plasma spraying of AlCoCrFeNi? Unlock High-Purity Coatings

- What are the key considerations when using an atmosphere protection muffle furnace? Ensure Safety and Precision for Your Lab