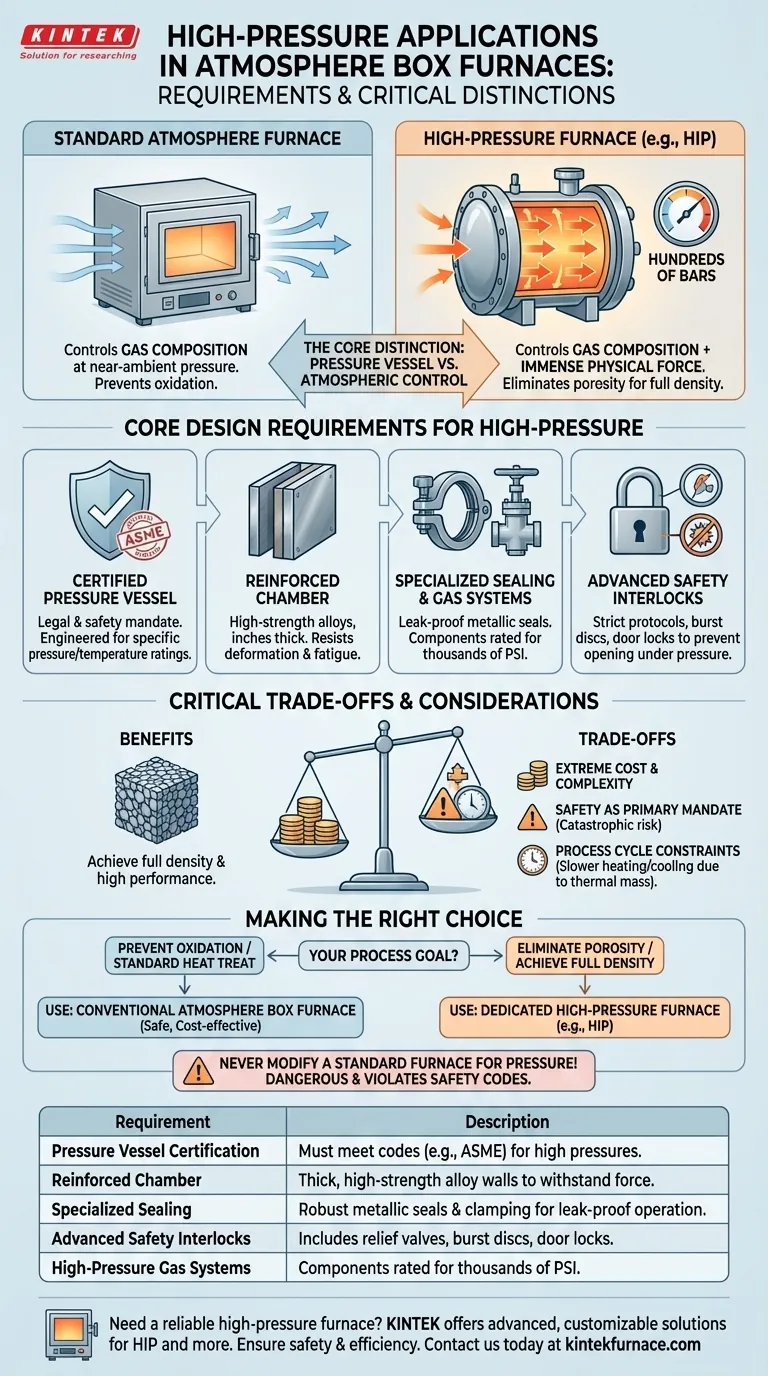

For high-pressure applications, a standard atmosphere box furnace is fundamentally unsuitable. Instead, you require a highly specialized system designed from the ground up to operate as a pressure vessel, capable of safely containing pressures up to several hundred bars. These systems feature certified, reinforced chambers and strict safety protocols to manage the significant operational risks.

The core distinction is that a standard atmosphere furnace controls gas composition at near-ambient pressure, while a high-pressure furnace is engineered to control both gas composition and immense physical force. This makes it an entirely different class of equipment governed by stringent pressure vessel safety codes.

From Atmospheric Control to Pressure Containment

To understand the requirements for high-pressure work, it is essential to first distinguish it from the function of a standard atmosphere furnace.

What Defines a Standard Atmosphere Furnace?

A conventional atmosphere box furnace is designed to control the chemical environment around a part during heating.

Its primary purpose is to prevent oxidation or other unwanted reactions by displacing ambient air. This is achieved by introducing inert gases like nitrogen and argon or reducing gases like hydrogen.

These furnaces typically operate at a slight positive pressure—just enough to ensure process gas flows out and air does not leak in. They are not designed to contain significant force.

The High-Pressure Requirement: A Paradigm Shift

High-pressure applications, such as Hot Isostatic Pressing (HIP) or high-pressure sintering, use pressure as a primary processing tool.

The goal is to apply uniform, isostatic pressure to a component at elevated temperatures. This force physically closes internal voids and porosity, allowing for the creation of fully dense, high-performance materials that are impossible to achieve otherwise.

This shift from simply controlling the gas type to using gas to exert immense force changes every aspect of the furnace's design.

Core Design Requirements for High-Pressure Furnaces

A furnace capable of handling high-pressure processes is built around principles of mechanical engineering and safety, not just thermal and atmospheric control.

The Pressure Vessel as the Foundation

The entire heated chamber must be contained within or function as a certified pressure vessel.

This is not a suggestion but a legal and safety mandate in most jurisdictions (e.g., following ASME Boiler and Pressure Vessel Code). The vessel is engineered with a specific pressure and temperature rating that cannot be exceeded.

Reinforced Chamber and Structural Integrity

The term "reinforced chamber" refers to walls made of high-strength steel alloys, often many inches thick, designed to resist deformation and fatigue under cyclic pressure and temperature.

The design, welding, and material selection are rigorously controlled and inspected to prevent catastrophic failure.

Specialized Sealing and Gas Systems

A simple door with a soft gasket is inadequate. High-pressure furnaces use robust, often metallic, seals and complex clamping mechanisms to ensure a leak-proof closure.

Furthermore, the entire gas supply system, including valves, tubing, and regulators, must be rated for the target pressure, which can be in the thousands of PSI (hundreds of bars).

Advanced Safety Interlocks

These furnaces are equipped with strict safety protocols and non-negotiable interlocks. This includes pressure relief valves and burst discs to prevent over-pressurization, and systems that make it physically impossible to open the furnace door while the chamber is pressurized.

Understanding the Critical Trade-offs

Moving to a high-pressure system involves significant trade-offs that must be weighed against the process benefits.

Extreme Cost and Complexity

A high-pressure furnace is an order of magnitude more expensive than a standard atmosphere furnace of similar size due to the specialized materials, engineering, and safety certifications required. Their operation and maintenance demand a higher level of technical expertise.

Safety as the Primary Mandate

The stored energy in a large, high-pressure, high-temperature system is immense. A failure would be catastrophic. Consequently, operations are governed by rigorous safety procedures, operator training, and mandatory inspection and recertification schedules.

Process Cycle Constraints

The thick walls of the pressure vessel create significant thermal mass. This can limit the achievable heating and cooling rates compared to a thin-walled standard furnace, potentially extending process cycle times.

Making the Right Choice for Your Process

Your process goals directly dictate the type of equipment you need. There is no crossover between standard and high-pressure furnace capabilities.

- If your primary focus is preventing oxidation or performing standard heat treatments: A conventional atmosphere box furnace is the correct, safe, and cost-effective tool.

- If your primary focus is eliminating internal material porosity or achieving full density: You must use a dedicated high-pressure furnace system, such as a Hot Isostatic Press.

- If you are considering modifying a standard furnace for pressure: Do not. It is not feasible, is exceptionally dangerous, and violates safety regulations.

Understanding this fundamental distinction between atmospheric control and pressure containment is the key to selecting a safe, effective, and appropriate thermal processing system.

Summary Table:

| Requirement | Description |

|---|---|

| Pressure Vessel Certification | Must meet ASME or similar codes for safe operation at high pressures (up to hundreds of bars). |

| Reinforced Chamber | Built with high-strength steel alloys and thick walls to withstand deformation and fatigue. |

| Specialized Sealing | Uses robust metallic seals and clamping mechanisms to ensure leak-proof operation. |

| Advanced Safety Interlocks | Includes pressure relief valves, burst discs, and door locks to prevent accidents. |

| High-Pressure Gas Systems | Components rated for thousands of PSI to handle gas composition and force control. |

Need a reliable high-pressure furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for high-pressure applications such as Hot Isostatic Pressing. Contact us today to discuss how our tailored furnace systems can enhance your material processing safety and efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing