The most critical considerations when using an atmosphere protection muffle furnace are ensuring absolute control over the two core variables: temperature uniformity and atmospheric stability. These factors, combined with rigorous safety protocols to manage hazards like high heat and potential pressure buildup, are essential for achieving successful, repeatable results for sensitive material processing.

An atmosphere furnace is more than a simple oven; it is a precision environmental chamber. Success depends on mastering the interplay between thermal management and atmospheric integrity, as any deviation in one can compromise the entire process.

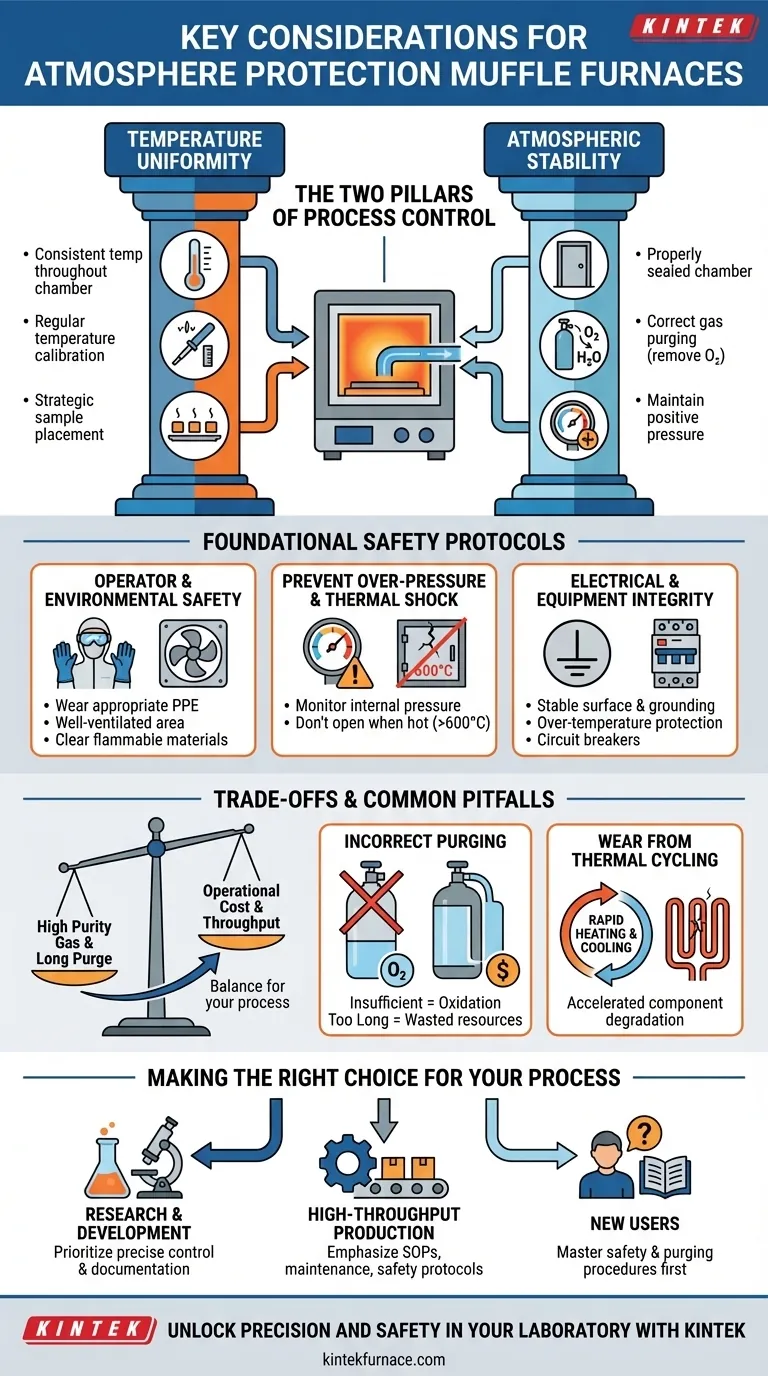

The Two Pillars of Process Control

The primary purpose of an atmosphere furnace is to create a highly specific, controlled environment. Your success hinges on your ability to manage both the thermal and chemical aspects of that environment without compromise.

Achieving Precise Temperature Uniformity

Consistent temperature throughout the entire chamber is non-negotiable for repeatable outcomes. If one part of your sample is hotter than another, its material properties will vary.

Key practices include performing regular temperature calibration to ensure the furnace's display matches the actual internal temperature. You must also understand the furnace's specified heat distribution uniformity and place samples strategically to ensure even exposure.

Maintaining Atmospheric Stability

The "atmosphere protection" is what separates this furnace from a standard model. It is designed to prevent unwanted chemical reactions, primarily oxidation, by replacing ambient air with an inert or reactive gas.

Achieving this requires a properly sealed chamber and a correct gas purging procedure. The goal is to flush out all oxygen and moisture before the heating cycle begins and maintain a slight positive pressure with the protective gas to prevent air from leaking in.

Foundational Safety Protocols

Operating equipment at extreme temperatures within a sealed, pressurized environment demands a strict adherence to safety. These protocols protect the operator, the equipment, and the integrity of your work.

Operator and Environmental Safety

Always wear appropriate personal protective equipment (PPE), including heat-resistant gloves and safety goggles. Handling samples or touching the furnace body can cause severe burns.

Ensure the furnace is operated in a well-ventilated area to safely dissipate any potential fumes or gases released during the process. The workspace must be clear of all flammable, explosive, or corrosive materials.

Preventing Over-Pressure and Thermal Shock

A sealed chamber will experience pressure changes as gas is introduced and heated. It is vital to monitor the internal pressure and ensure it does not exceed safe limits, which could lead to an accident.

Never open the furnace door at extremely high temperatures (e.g., above 600°C). The sudden thermal shock can damage the furnace's refractory materials and create a significant safety hazard for the operator.

Electrical and Equipment Integrity

The furnace must be placed on a stable, non-combustible surface and connected to a properly rated electrical circuit with appropriate grounding and fuses.

Familiarize yourself with built-in safety mechanisms like over-temperature protection and circuit breakers. These features are your last line of defense against equipment failure.

Understanding the Trade-offs and Common Pitfalls

Effective use of an atmosphere furnace requires balancing ideal conditions with practical limitations. Understanding these trade-offs is key to avoiding failed experiments and unnecessary costs.

The Purity vs. Cost Dilemma

Using high-purity inert gas (like Argon 5.0) and executing long purge cycles ensures the best possible atmosphere. However, this increases operational costs and reduces throughput. You must determine the minimum purity and purge time that is acceptable for your specific process.

The Risk of Incorrect Purging

This is the most common point of failure. An insufficient purge will leave residual oxygen in the chamber, leading to oxidation and a ruined sample. Conversely, purging for too long wastes expensive gas and time. Developing a standardized, validated purging protocol is critical.

Wear from Thermal Cycling

Heating elements, thermocouples, and refractory insulation degrade over time, a process accelerated by rapid heating and cooling cycles. While fast cycles can increase throughput, they also shorten the lifespan of critical components and necessitate more frequent maintenance.

Making the Right Choice for Your Process

Your operational focus should align directly with the goal of your work. Whether for research or production, a disciplined approach is paramount.

- If your primary focus is research and development: Prioritize precise atmospheric control and meticulous documentation of all parameters, including gas flow rates and purge times, to ensure experiment repeatability.

- If your primary focus is high-throughput production: Emphasize developing standardized operating procedures (SOPs), routine maintenance schedules, and robust safety protocols to maximize uptime and consistency.

- If you are new to the equipment: Concentrate on mastering the fundamental safety procedures and understanding the purge process before attempting highly sensitive or valuable experiments.

Ultimately, treating the furnace as a precision instrument—not just a heat source—is the key to achieving reliable and safe outcomes.

Summary Table:

| Consideration | Key Points |

|---|---|

| Temperature Uniformity | Regular calibration, strategic sample placement for even heating |

| Atmospheric Stability | Proper sealing, correct gas purging, positive pressure maintenance |

| Safety Protocols | Use PPE, ensure ventilation, monitor pressure, avoid thermal shock |

| Common Pitfalls | Balance gas purity vs. cost, avoid incorrect purging, manage thermal cycling wear |

Unlock Precision and Safety in Your Laboratory with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in R&D or production, our expertise ensures reliable, safe, and efficient processes tailored to your needs.

Contact us today to discuss how our solutions can optimize your atmosphere furnace operations and deliver superior results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What are the applications of inert atmosphere furnaces? Essential for Metal Processing, Electronics, and Additive Manufacturing

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment