In material research, a controlled atmosphere furnace is used to synthesize, process, and test materials at high temperatures within a precisely managed gaseous environment. This control prevents unwanted chemical reactions, primarily oxidation from the air, and allows researchers to intentionally direct the formation of a material's final structure, composition, and properties.

The core function of a controlled atmosphere furnace is not just to heat a material, but to eliminate the unpredictable variable of air. By replacing it with a specific gas or a vacuum, researchers gain the precise control needed to create and modify materials at a fundamental level.

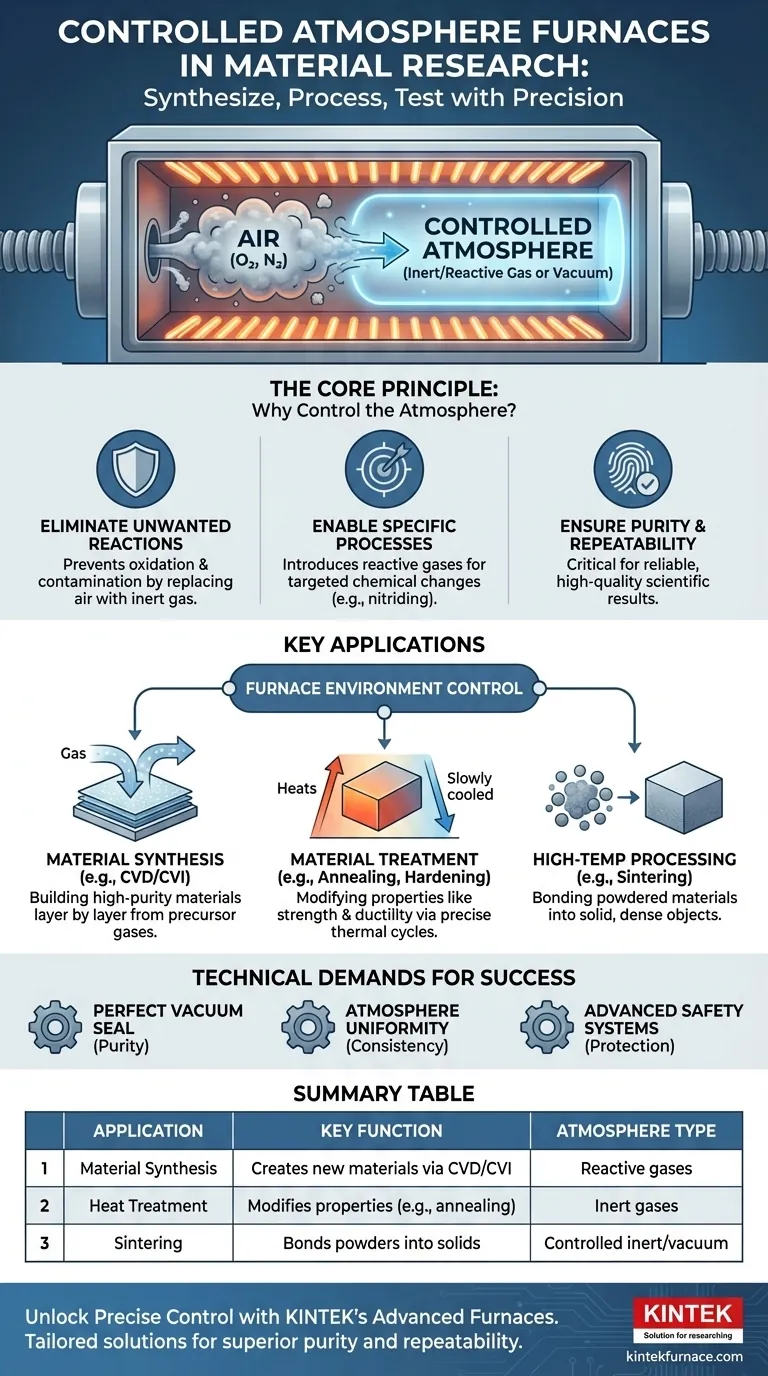

The Core Principle: Why Control the Atmosphere?

At its heart, using a controlled atmosphere is about managing chemistry at high temperatures. When materials get hot, they become highly reactive, and the standard air around us is a mixture of reactive gases—primarily nitrogen and oxygen.

Eliminating Unwanted Reactions

Most materials, especially metals, will readily react with oxygen at high temperatures in a process called oxidation. This forms an oxide layer (like rust) that contaminates the sample and fundamentally alters its properties.

A controlled atmosphere furnace prevents this by first removing the air (creating a vacuum) and then backfilling the chamber with an inert gas, such as argon or nitrogen, that will not react with the material.

Enabling Specific Chemical Processes

Some advanced processes require a specific, reactive atmosphere to work. The furnace provides a sealed environment to introduce these gases safely and effectively.

Examples include nitriding, where nitrogen gas is used to harden the surface of steel, or carburizing, which uses carbon-rich gases. Without a controlled environment, these targeted reactions would be impossible.

Ensuring Purity and Repeatability

For scientific research, results must be repeatable. A controlled atmosphere ensures that any changes in the material are a direct result of the intended process (e.g., temperature profile, specific gas) and not random contamination from the air.

This high level of purity is essential for developing high-quality materials and for fundamental studies exploring how different atmospheres affect material behavior.

Key Applications in Material Research

By providing this level of environmental control, these furnaces become indispensable for a wide range of research and development tasks.

Material Synthesis and Creation

Processes like Chemical Vapor Deposition (CVD) and Chemical Vapor Infiltration (CVI) rely entirely on a controlled atmosphere. In these techniques, precursor gases are introduced into the furnace, where they react and "deposit" a new, solid material onto a substrate, building it up layer by layer.

This method is used to create high-purity thin films, advanced coatings, and composite materials.

Material Treatment and Enhancement

Heat treatment is used to modify the properties of existing materials. A controlled atmosphere is critical for achieving the desired outcome without introducing defects.

- Annealing: Heating and slowly cooling a material to relieve internal stresses and increase its ductility.

- Hardening: Heating and rapidly cooling a material to increase its strength and wear resistance.

- Tempering: A low-temperature heat treatment used to reduce the brittleness of a hardened material.

High-Temperature Processing

Many advanced materials are formed by consolidating powders at extreme temperatures.

Sintering, for example, is a process where powdered materials (like ceramics or metals) are heated below their melting point until their particles bond together, forming a dense, solid object. A controlled atmosphere is vital to prevent oxidation and ensure strong, pure bonds between particles.

Understanding the Technical Demands

Using a controlled atmosphere furnace is not without its challenges. The effectiveness of the entire process hinges on the quality and integrity of the equipment itself.

The Importance of a Perfect Seal

The entire purpose of the furnace is defeated if outside air can leak into the chamber. A vacuum-tight seal is the single most critical feature, ensuring that the atmosphere inside remains pure and precisely controlled throughout the high-temperature process.

Atmosphere Uniformity

The flow of gas within the furnace must be uniform to ensure every part of the material is exposed to the same conditions. Inconsistent gas distribution leads to inconsistent material properties, rendering research results unreliable.

Safety with Hazardous Gases

Many processes use gases that can be flammable (hydrogen), toxic (ammonia), or operate at high pressures. Advanced safety systems, including automatic shut-offs, pressure relief valves, and explosion protection, are non-negotiable for protecting both the user and the facility.

Making the Right Choice for Your Goal

The specific application dictates the most important furnace features and process parameters.

- If your primary focus is creating new, high-purity materials: Prioritize a furnace with excellent vacuum capabilities and precise gas flow control for processes like CVD.

- If your primary focus is optimizing existing materials: Concentrate on achieving precise temperature uniformity and atmosphere stability for heat treatments like annealing or tempering.

- If your primary focus is fundamental research: You need a flexible system that allows you to easily and safely switch between different inert and reactive gases to study their effects on a material.

Ultimately, a controlled atmosphere furnace transforms high-temperature work from an unpredictable art into a precise and repeatable science.

Summary Table:

| Application | Key Function | Atmosphere Type |

|---|---|---|

| Material Synthesis | Creates new materials via CVD/CVI | Reactive gases (e.g., for nitriding) |

| Heat Treatment | Modifies material properties (e.g., annealing) | Inert gases (e.g., argon, nitrogen) |

| Sintering | Bonds powdered materials into solids | Controlled inert or vacuum environments |

Unlock precise material control with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met for superior purity and repeatability. Contact us today to discuss how our furnaces can enhance your material research and drive innovation!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What does nitrogen do in a furnace? Create an Inert, Oxygen-Free Atmosphere for Superior Results

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance