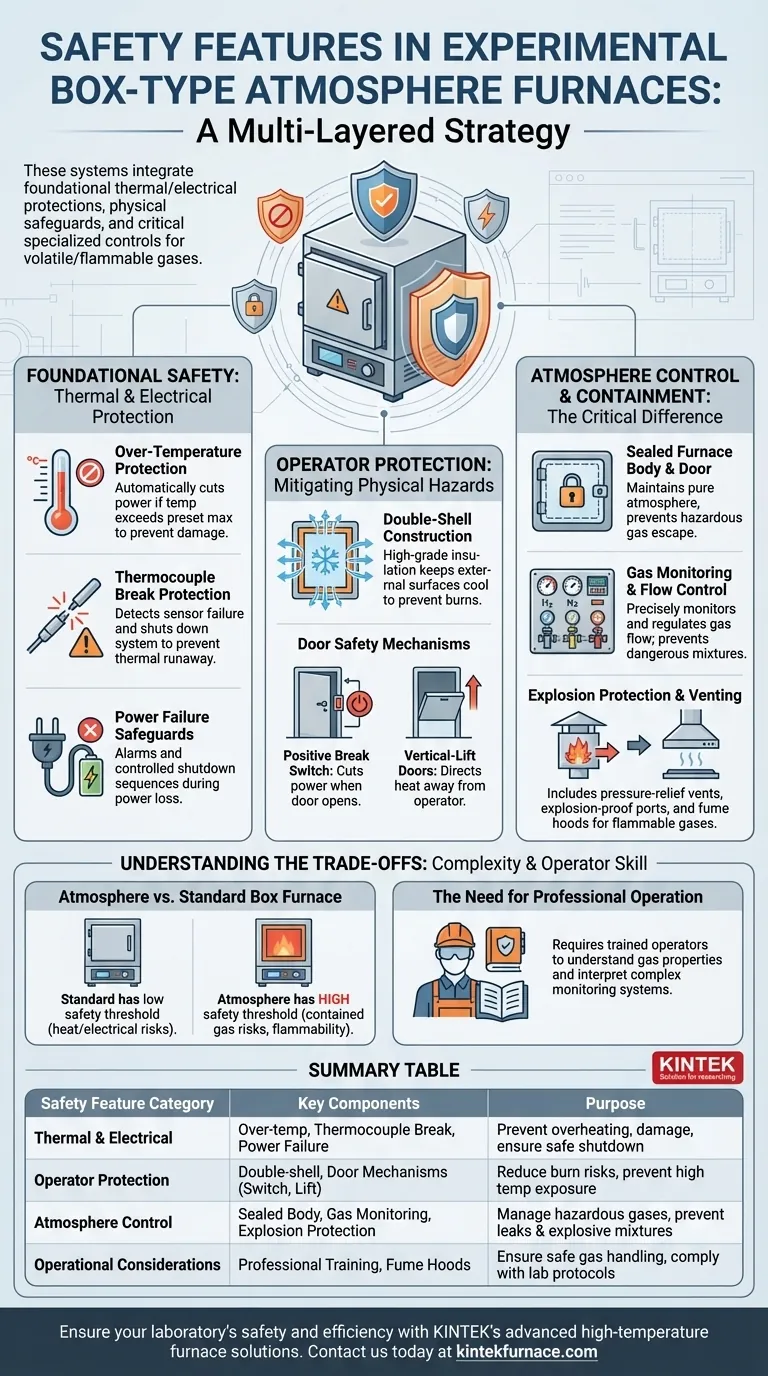

At their core, experimental box-type atmosphere furnaces are engineered with a multi-layered safety strategy. These systems integrate fundamental thermal and electrical protections like alarms for overheating and power failure, physical safeguards such as double-shell construction to keep exterior surfaces cool, and—most critically—specialized controls to manage the risks associated with volatile or flammable gases, including sealed bodies, gas monitoring, and explosion-proof devices.

The key distinction to understand is that while standard box furnaces focus on managing heat, atmosphere furnaces add a crucial layer of safety to contain and control potentially hazardous gases. This elevates their complexity and the operational diligence they require.

Foundational Safety: Thermal and Electrical Protection

All high-temperature furnaces share a common set of risks related to extreme heat and the electricity required to generate it. Atmosphere furnaces build upon this foundation with several automated protections.

Over-Temperature and Thermocouple Protection

The primary safety system is over-temperature protection. This function automatically cuts power to the heating elements if the furnace exceeds a preset maximum temperature, preventing damage to the unit, the sample, and the surrounding lab.

This is often paired with thermocouple break protection. A thermocouple is the furnace's temperature sensor; if it fails, the controller could be left "blind," potentially leading to a dangerous thermal runaway. The system detects this failure and safely shuts down.

Power Failure Safeguards

An unexpected power loss can compromise a sensitive process. Safety systems are designed to manage this event, often including alarms and controlled shutdown sequences to prevent damage upon power restoration.

Operator Protection: Mitigating Physical Hazards

Protecting the user from direct contact with high temperatures is a paramount design consideration, addressed through the furnace's physical construction.

Double-Shell Construction

Modern furnaces feature a double-layered shell with high-grade insulation. This design allows for airflow between the inner and outer walls, drastically lowering the external surface temperature and protecting operators from severe burns.

Door Safety Mechanisms

The furnace door is a critical point of interaction. A positive break safety switch is a common feature that immediately cuts power to the heating elements when the door is opened, preventing exposure to direct radiation.

Some designs also use vertical-lift doors. This keeps the intensely hot inner face of the door pointed safely upward and away from the operator when open.

The Critical Difference: Atmosphere Control and Containment

The defining feature of an atmosphere furnace is its use of specific gases. This introduces significant risks—namely flammability, explosivity, or asphyxiation—which require specialized safety systems.

Sealed Furnace Body

To maintain a pure internal atmosphere and prevent hazardous gases from escaping, these furnaces have a sealed body and door. This containment is crucial for both the integrity of the experiment and the safety of the lab environment.

Gas Monitoring and Flow Control

These furnaces incorporate systems to precisely monitor and regulate gas flow. This is not just for process control; it is a vital safety feature to ensure the correct mixture of gases is present and to prevent the ingress of outside air, which could create a flammable or explosive mixture.

Explosion Protection and Venting

For processes involving flammable gases like hydrogen, explosion-proof devices are mandatory. These can include pressure-relief vents or "explosion-proof" ports designed to safely direct the force of a potential deflagration.

These systems are often supplemented by requirements for fume hoods or local exhaust ventilation to safely manage and remove any escaped gases from the work area.

Understanding the Trade-offs: Complexity and Operator Skill

While robust, these safety features come with inherent trade-offs in complexity and operational requirements. Failing to appreciate this difference is a common pitfall.

Atmosphere vs. Standard Box Furnace

A standard box furnace used for heating in ambient air has a relatively low safety threshold. Its primary risks are thermal and electrical, managed by basic temperature protection.

An atmosphere furnace, by contrast, operates with a much higher safety threshold. The presence of contained gases, which may be flammable or inert, necessitates a deep understanding of gas handling and monitoring.

The Need for Professional Operation

The advanced safety systems of an atmosphere furnace are not "set and forget." They require trained, professional operators who understand the properties of the gases being used and can correctly interpret the furnace's monitoring systems. The operator is an integral part of the overall safety equation.

Making the Right Choice for Your Goal

Your specific process dictates the necessary level of safety engineering. Use your primary goal to determine the essential features.

- If your primary focus is simple heat treatment in air: A standard box furnace with foundational over-temperature and door safety interlocks is sufficient and far simpler to operate.

- If your process requires an inert or reactive gas: An atmosphere furnace is mandatory. Prioritize a well-sealed chamber, precise gas flow control, and reliable monitoring as non-negotiable features.

- If you are working with flammable or explosive gases: You must select a furnace with certified explosion-proof devices, pressure-relief systems, and a clear plan for exhaust ventilation.

Understanding how these safety features align with your specific application is the first step toward ensuring a secure and successful experimental environment.

Summary Table:

| Safety Feature Category | Key Components | Purpose |

|---|---|---|

| Thermal and Electrical Protection | Over-temperature protection, Thermocouple break protection, Power failure safeguards | Prevent overheating, equipment damage, and ensure safe shutdowns |

| Operator Protection | Double-shell construction, Door safety mechanisms (e.g., positive break switch, vertical-lift doors) | Reduce burn risks and prevent exposure to high temperatures |

| Atmosphere Control and Containment | Sealed furnace body, Gas monitoring and flow control, Explosion protection and venting | Manage hazardous gases, prevent leaks, and avoid explosive mixtures |

| Operational Considerations | Professional operator training, Ventilation requirements (e.g., fume hoods) | Ensure safe handling of gases and compliance with lab protocols |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, incorporating essential safety features for hazardous gas and heat management. Contact us today to discuss how we can enhance your lab's performance and safety!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process