Spark Plasma Sintering (SPS) fundamentally alters the manufacturing landscape by utilizing pulsed direct current and axial pressure to achieve densification in minutes rather than hours. Unlike traditional methods that rely on slow external heating, SPS generates heat internally, allowing for rapid temperature ramp-ups that bypass the thermal lag responsible for grain coarsening.

The core advantage of SPS is its ability to decouple densification from grain growth. By combining extreme heating rates with mechanical pressure, it "locks in" high-performance nanocrystalline features—such as dislocations and nano-precipitates—that are typically destroyed during the prolonged dwell times of conventional sintering.

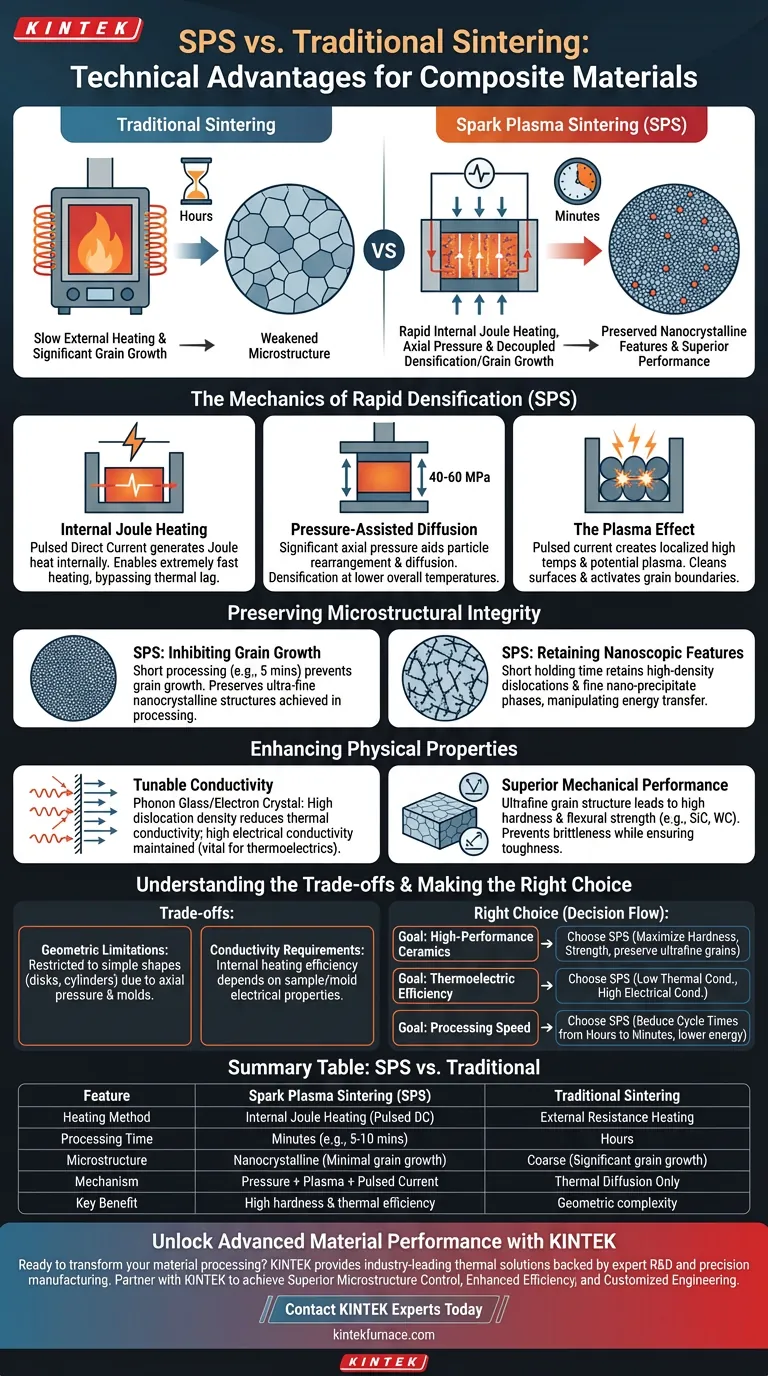

The Mechanics of Rapid Densification

Internal Joule Heating

Traditional resistance furnaces heat a sample from the outside in, which is slow and inefficient.

In contrast, SPS passes pulsed electric current directly through the mold or the conducting sample itself. This generates Joule heat internally, enabling extremely fast heating rates.

Pressure-Assisted Diffusion

SPS does not rely on heat alone; it applies significant axial pressure (e.g., 40–60 MPa) throughout the process.

This pressure physically aids in particle rearrangement and promotes diffusion at grain boundaries. Consequently, full densification can be achieved at lower overall temperatures compared to pressureless sintering.

The Plasma Effect

The pulsed current creates specific conditions at particle contact points, including potential plasma discharge and localized high temperatures.

This effectively cleans particle surfaces and activates grain boundaries, further accelerating the bonding process.

Preserving Microstructural Integrity

Inhibiting Grain Growth

In traditional sintering, keeping a material hot enough to densify usually gives grains time to grow large, which weakens the material.

SPS completes the process so quickly—often within 5 minutes—that grain growth is effectively inhibited. This preserves the ultra-fine or nanocrystalline structures achieved during earlier processing stages, such as mechanical alloying.

Retaining Nanoscopic Features

Because the holding time is short, the material retains high-density dislocations and fine nano-precipitate phases.

These features are critical for advanced applications because they manipulate how energy moves through the material.

Enhancing Physical Properties

Tunable Conductivity (The Phonon Glass/Electron Crystal Concept)

The microstructural features preserved by SPS create a unique advantage for functional composites.

The high density of dislocations and grain boundaries significantly enhances phonon scattering, which reduces thermal conductivity. Simultaneously, the process maintains high electrical conductivity, a rare combination vital for thermoelectric materials.

Superior Mechanical Performance

The ability to maintain an ultrafine grain structure directly translates to mechanical gains.

For ceramics like Silicon Carbide (SiC) or Tungsten Carbide (WC), this results in a material that possesses both high hardness and high flexural strength. By melting binders (like cobalt) locally without overheating the bulk, SPS prevents brittleness while ensuring toughness.

Understanding the Trade-offs

Geometric Limitations

The reliance on axial pressure and specific molds imposes constraints on component geometry.

While SPS is superior for simple shapes like disks or cylinders, it cannot easily replicate the complex 3D geometries achievable with pressureless sintering or slip casting.

Material Conductivity Requirements

The efficiency of the internal heating mechanism depends heavily on the electrical properties of the sample and the mold.

Non-conductive materials must rely entirely on the mold for heat transfer, which can slightly alter the heating dynamics compared to conductive samples that self-heat.

Making the Right Choice for Your Goal

To determine if SPS is the correct manufacturing route for your composite, consider your specific performance targets:

- If your primary focus is High-Performance Ceramics: Choose SPS to achieve maximum hardness and flexural strength by preserving ultrafine grain structures that traditional hot-pressing would destroy.

- If your primary focus is Thermoelectric Efficiency: Choose SPS to engineer materials with low thermal conductivity (via phonon scattering) but high electrical conductivity.

- If your primary focus is Processing Speed: Choose SPS to reduce cycle times from hours to minutes, significantly lowering energy consumption per unit.

SPS is not just a faster heater; it is a tool for freezing non-equilibrium microstructures into fully dense solids.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Sintering |

|---|---|---|

| Heating Method | Internal Joule Heating (Pulsed DC) | External Resistance Heating |

| Processing Time | Minutes (e.g., 5-10 mins) | Hours |

| Microstructure | Nanocrystalline (Minimal grain growth) | Coarse (Significant grain growth) |

| Mechanism | Pressure + Plasma + Pulsed Current | Thermal Diffusion Only |

| Key Benefit | High hardness & thermal efficiency | Geometric complexity |

Unlock Advanced Material Performance with KINTEK

Ready to transform your material processing from hours to minutes? KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing.

Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our laboratory high-temperature furnaces are fully customizable to meet the unique demands of Spark Plasma Sintering and beyond.

Partner with KINTEK to achieve:

- Superior Microstructure Control: Preserve nanocrystalline features for maximum strength.

- Enhanced Efficiency: Reduce energy consumption with rapid heating cycles.

- Customized Engineering: Solutions tailored specifically to your composite material needs.

Contact KINTEK Experts Today to discover how our advanced sintering technology can elevate your lab's capabilities!

Visual Guide

References

- Xian Yi Tan, Qingyu Yan. Synergistic Combination of Sb <sub>2</sub> Si <sub>2</sub> Te <sub>6</sub> Additives for Enhanced Average ZT and Single‐Leg Device Efficiency of Bi <sub>0.4</sub> Sb <sub>1.6</sub> Te <sub>3</sub> ‐based Composites. DOI: 10.1002/advs.202400870

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What core functions do high-purity graphite molds perform during the SPS of LaFeO3? Optimize Your Sintering Process

- What are the advantages of using Spark Plasma Sintering (SPS) for Mo-Cr-Y composites? High-Performance Fabrication

- What are the advantages of using a HIP sintering system over conventional sintering for Bismuth Telluride composites?

- How does a graphite mold influence high-entropy alloys in VHPS? Enhance Strength via In-Situ Carbides

- What factors should be considered when selecting vacuum press equipment? Key Insights for Optimal Performance

- What are the advantages of using a vacuum or protected atmosphere in sintering? Boost Material Purity and Performance

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What are the key advantages of vacuum hot press furnaces compared to conventional furnaces? Achieve Superior Purity and Control