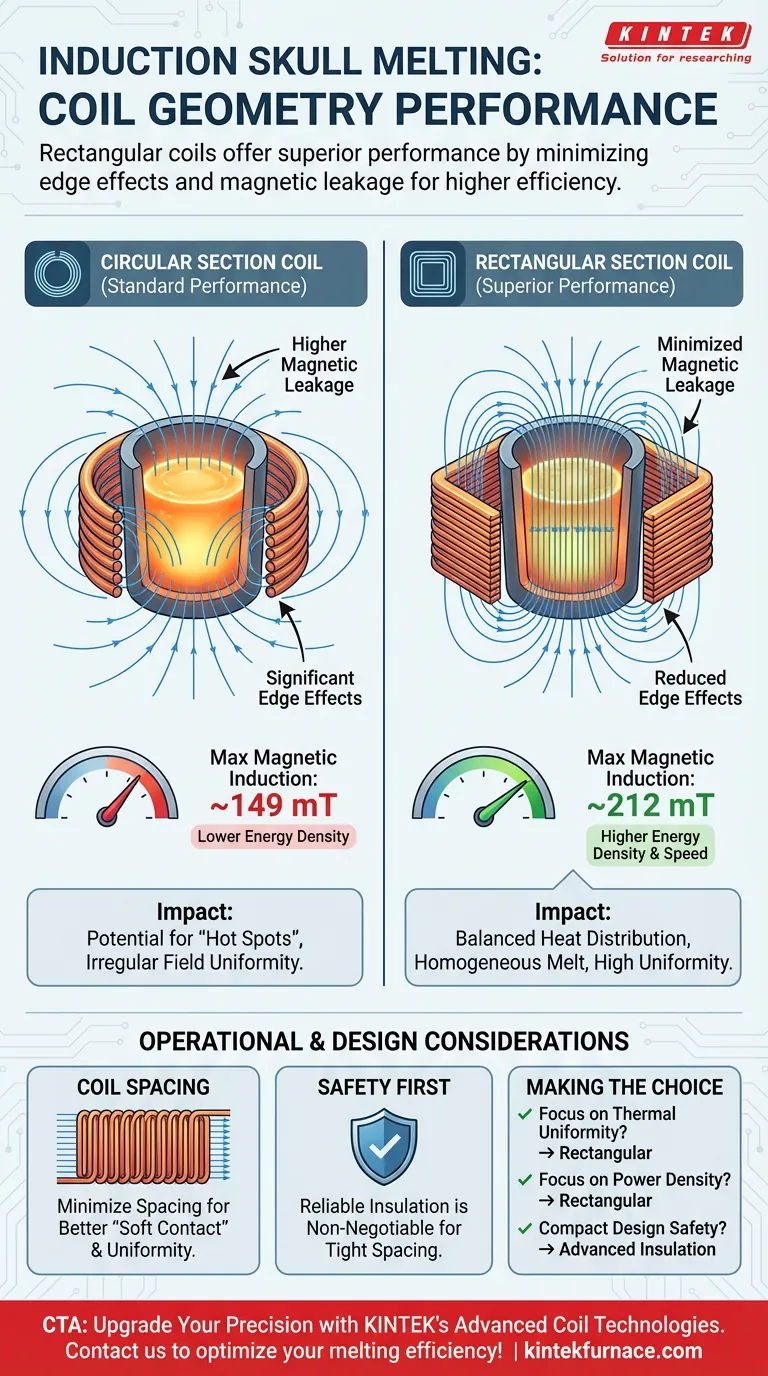

Rectangular section induction coils offer superior performance compared to circular section coils in Induction Skull Melting (ISM) processes. By minimizing edge effects and magnetic leakage, rectangular coils achieve a significantly higher maximum magnetic induction intensity—212 mT versus 149 mT for circular coils of the same cross-sectional area—leading to more efficient and uniform melting.

Core Takeaway Switching from circular to rectangular coil geometry fundamentally alters the magnetic field distribution, reducing leakage and "edge effects." This results in a more uniform electric field within the charge, ensuring balanced heat distribution and higher thermal efficiency.

The Physics of Coil Geometry

Maximizing Magnetic Induction

The cross-sectional shape of the coil material dictates the intensity of the magnetic field it can generate. Under identical cross-sectional area conditions, the geometry of a rectangular coil allows for a much denser magnetic field.

Data indicates that rectangular coils can produce a maximum magnetic induction intensity of approximately 212 mT.

In contrast, circular coils under the same conditions typically peak at around 149 mT. This substantial difference means rectangular coils deliver more energy to the process.

Reducing Magnetic Leakage

Circular coils, due to their rounded edges, naturally create larger gaps and irregularities in the field distribution.

Rectangular coils provide a flatter profile that minimizes magnetic leakage. By reducing the stray magnetic flux that escapes the target area, the system directs more energy directly into the melting crucible.

Minimizing Edge Effects

"Edge effects" refer to the distortion of the magnetic field at the boundaries of the conductor.

Rectangular sections significantly reduce these edge effects compared to circular sections. This leads to a more uniform excitation magnetic field throughout the melting zone.

Impact on Melting Performance

Uniformity of the Electric Field

The quality of the magnetic field directly dictates the behavior of the electric field induced within the charge material.

Because rectangular coils lower magnetic leakage, they promote more uniform electric fields inside the metal being melted. A consistent electric field is a prerequisite for controlled processing.

Achieving Balanced Heat Distribution

Inconsistencies in induction coils often lead to "hot spots" or uneven melting.

The uniformity provided by rectangular coils results in balanced heat distribution throughout the charge. This is critical for achieving a homogeneous melt and ensuring high metallurgical quality.

Operational Trade-offs and Design

The Impact of Coil Spacing

To fully leverage the benefits of coil geometry, the spacing between turns should be minimized.

Reducing the spacing between turns further minimizes magnetic leakage and enhances the uniformity of the magnetic field along the vertical axis. This supports better "soft contact" effects (uniform magnetic levitation).

Safety and Insulation Requirements

While tighter coil spacing improves performance, it introduces electrical risks.

When reducing turn spacing to optimize the field, reliable insulation is non-negotiable. Specialized coatings must be applied to the coils to prevent short circuits and ensure safe operation.

Making the Right Choice for Your Goal

The choice between rectangular and circular coils depends on your specific performance requirements and fabrication capabilities.

- If your primary focus is Thermal Uniformity: Choose rectangular coils to minimize edge effects and ensure balanced heat distribution across the melt.

- If your primary focus is Power Density: Opt for rectangular sections to achieve higher magnetic induction intensity (up to 212 mT) for the same cross-sectional area.

- If your primary focus is Safety in Compact Designs: Ensure that any move toward rectangular, tightly wound coils is paired with advanced insulation coatings to prevent electrical faults.

Rectangular coils provide the magnetic precision and intensity required for high-efficiency Induction Skull Melting, provided they are insulated correctly.

Summary Table:

| Feature | Circular Section Coil | Rectangular Section Coil | Impact on Performance |

|---|---|---|---|

| Max Magnetic Induction | ~149 mT | ~212 mT | Higher energy density and melting speed |

| Magnetic Leakage | Higher (due to rounded geometry) | Lower (flatter profile) | Increased energy efficiency and focus |

| Edge Effects | Significant field distortion | Minimized distortion | More uniform excitation magnetic field |

| Heat Distribution | Potential for "hot spots" | Balanced and uniform | Higher metallurgical quality and consistency |

| Field Uniformity | Irregular | High uniformity | Essential for controlled processing and levitation |

Upgrade your Induction Skull Melting precision with KINTEK's advanced coil technologies. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your unique lab requirements. Whether you need to maximize power density or ensure perfect thermal uniformity, our team delivers the specialized high-temp furnace solutions your research demands. Contact KINTEK today to optimize your melting efficiency!

Visual Guide

References

- Chaojun Zhang, Jianfei Sun. Optimizing energy efficiency in induction skull melting process: investigating the crucial impact of melting system structure. DOI: 10.1038/s41598-024-56966-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the purpose of the vacuum chamber in an induction-heated vacuum furnace? Achieve Purity and Performance in Materials Processing

- How does IGBT technology increase melting capacity and productivity? Unlock Faster Melts and Higher Output

- What is an IGBT induction melting machine? Unlock Faster, More Efficient Metal Melting

- Why is the precise addition of alloying elements in induction furnaces necessary for heavy-section ADI?

- What are the advantages of using induction melting furnaces? Boost Efficiency, Quality, and Safety

- How does induction heating improve plastic injection molding? Boost Efficiency, Quality, and Speed

- Why is vacuum environment important in VIM furnaces? Achieve High-Purity Alloys with Precision Control

- What materials are crucibles in vacuum casting furnaces typically made of? Choose the Right Material for High-Purity Casts