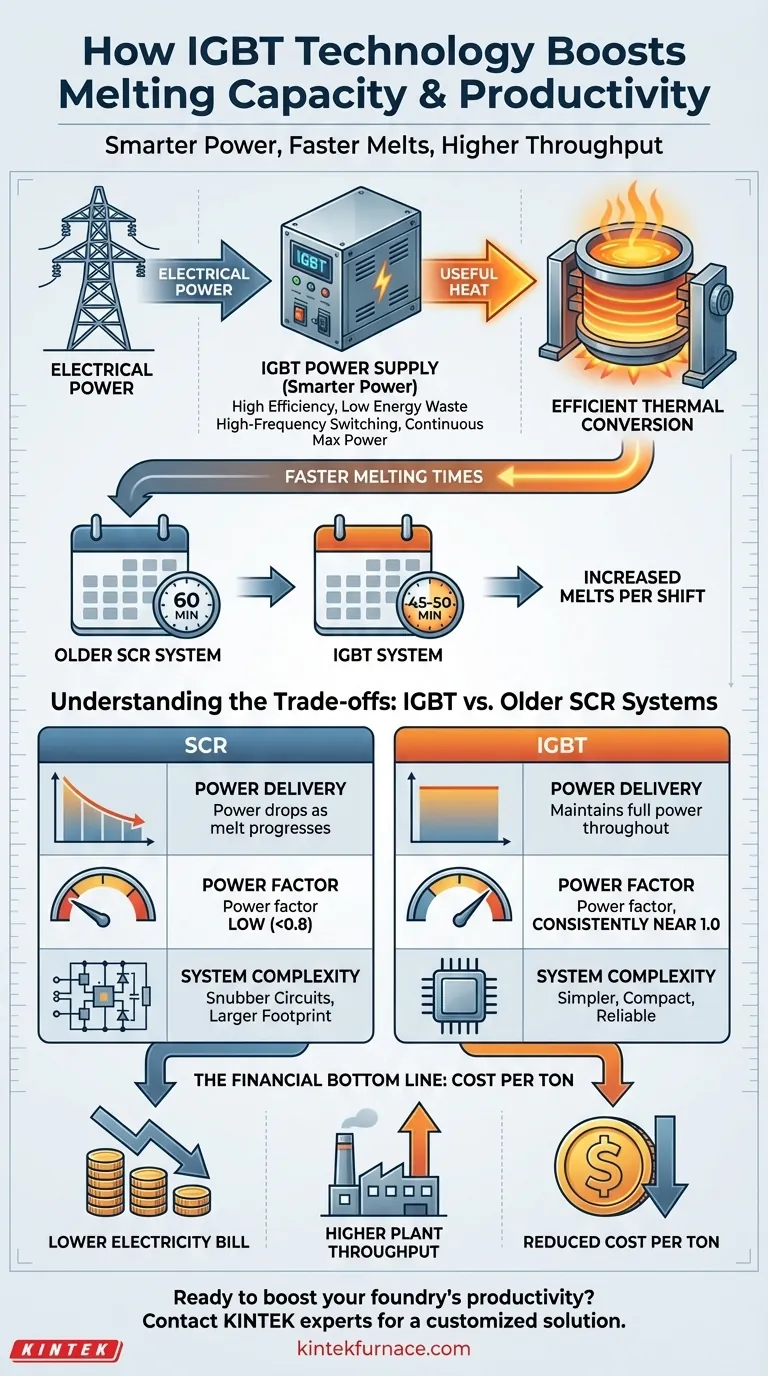

At its core, IGBT technology increases melting capacity by converting electrical energy into useful heat far more efficiently and precisely than older technologies. Its ability to operate at high frequencies allows the power supply to continuously deliver maximum power into the metal charge, significantly reducing the time it takes to complete a melt and thereby increasing the number of melts possible in a given shift.

The fundamental advantage of IGBTs is not just about providing power, but about providing smarter power. By minimizing energy waste and dynamically adapting to the melt, IGBT systems ensure that more of your electricity bill is spent on melting metal, not heating the control cabinet, leading directly to faster melts and higher productivity.

The Core Principle: From Electricity to Molten Metal

The goal of any induction furnace is to efficiently convert electrical power from the grid into thermal energy within the metal charge. The effectiveness of this conversion is almost entirely dependent on the performance of the power supply unit.

High Efficiency: Minimizing Wasted Energy

IGBTs (Insulated Gate Bipolar Transistors) are exceptionally efficient semiconductor switches. They have a very low on-state voltage drop and minimal power dissipation.

In simple terms, this means very little energy is lost as waste heat inside the power supply itself. More of the electrical power drawn from the grid is successfully converted and delivered to the furnace coil, where it can do useful work.

High Switching Frequency: The Key to Productivity

This is the most critical factor. IGBTs can switch on and off tens of thousands of times per second, far faster than older thyristor (SCR) technologies.

This high frequency allows the power supply to maintain a near-perfect power factor (close to 1.0) throughout the entire melting cycle. It can instantly adjust its output to match the changing electrical properties of the metal as it heats up and becomes molten.

Because the system can consistently deliver its full rated power to the load, the time required to input the necessary kilowatt-hours to melt the charge is dramatically shortened.

The Direct Impact: Faster Melts, Higher Throughput

Combining high efficiency and high-frequency control creates a clear outcome: faster melting times.

If an older system's power delivery drops off as the melt progresses, it might take 60 minutes to melt a charge. An IGBT system that holds maximum power from start to finish might complete the same melt in 45-50 minutes.

Over the course of a day, this time saving translates directly into one or more extra melts, increasing the plant's total output without adding more furnaces.

Understanding the Trade-offs: IGBT vs. Older SCR Systems

To appreciate the advance of IGBTs, it's useful to compare them directly to the Silicon-Controlled Rectifier (SCR) technology they replaced. The difference in performance is not subtle.

The Power Factor Problem in SCR Systems

SCR-based power supplies operate at a much lower frequency. A major drawback is that their power factor naturally declines as the furnace coil heats the charge.

This means that even if you have a 1,000 kW power supply, you may only be able to deliver 800 kW to the furnace for a significant portion of the melt cycle. This inefficiency directly extends the time and energy needed for each melt.

System Complexity and Reliability

SCR systems require additional, complex components like snubber circuits to operate correctly. These add points of failure and increase the physical size and maintenance burden of the power supply.

IGBT-based designs are inherently simpler and more compact. Eliminating these peripheral components results in a more robust and reliable system with a smaller footprint.

The Financial Bottom Line: Cost Per Ton

Ultimately, productivity is measured in cost. The technical advantages of IGBTs translate directly to financial savings.

Higher electrical efficiency means a lower electricity bill for the same amount of metal melted. Faster melting cycles mean higher plant throughput and better labor utilization. Together, these factors significantly reduce the cost to produce each ton of metal.

Making the Right Choice for Your Operation

Adopting IGBT technology is a strategic decision to improve the core metrics of your melting operation. Your primary goal will determine which benefit is most critical.

- If your primary focus is maximizing throughput: The ability of IGBTs to maintain full power throughout the melt cycle is the key advantage, as it directly reduces melt times and increases the number of heats per day.

- If your primary focus is reducing operational costs: The superior electrical efficiency and high power factor of IGBT systems will provide the most significant impact, lowering your energy consumption and potentially eliminating utility penalties.

Upgrading to an IGBT-based induction system is a direct investment in a faster, more cost-effective, and productive melting process.

Summary Table:

| Feature | IGBT System | Older SCR System |

|---|---|---|

| Power Delivery | Maintains full power throughout melt | Power drops as melt progresses |

| Power Factor | Consistently near 1.0 | Declines significantly |

| Switching Frequency | High (kHz range) | Low (Hz range) |

| Efficiency | High (minimal energy waste) | Lower (more energy lost as heat) |

| Typical Impact on Melt Time | Reduced (e.g., 45-50 min) | Longer (e.g., 60 min) |

Ready to boost your foundry's productivity and reduce your cost per ton?

At KINTEK, we leverage our advanced R&D and in-house manufacturing to provide robust, high-efficiency melting solutions. Whether your goal is maximizing daily throughput or minimizing operational costs, our IGBT-based induction furnace systems are engineered to deliver smarter power, faster melt times, and superior reliability.

Contact our melting experts today to discuss how we can customize a solution to meet your unique production targets and drive your profitability.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys