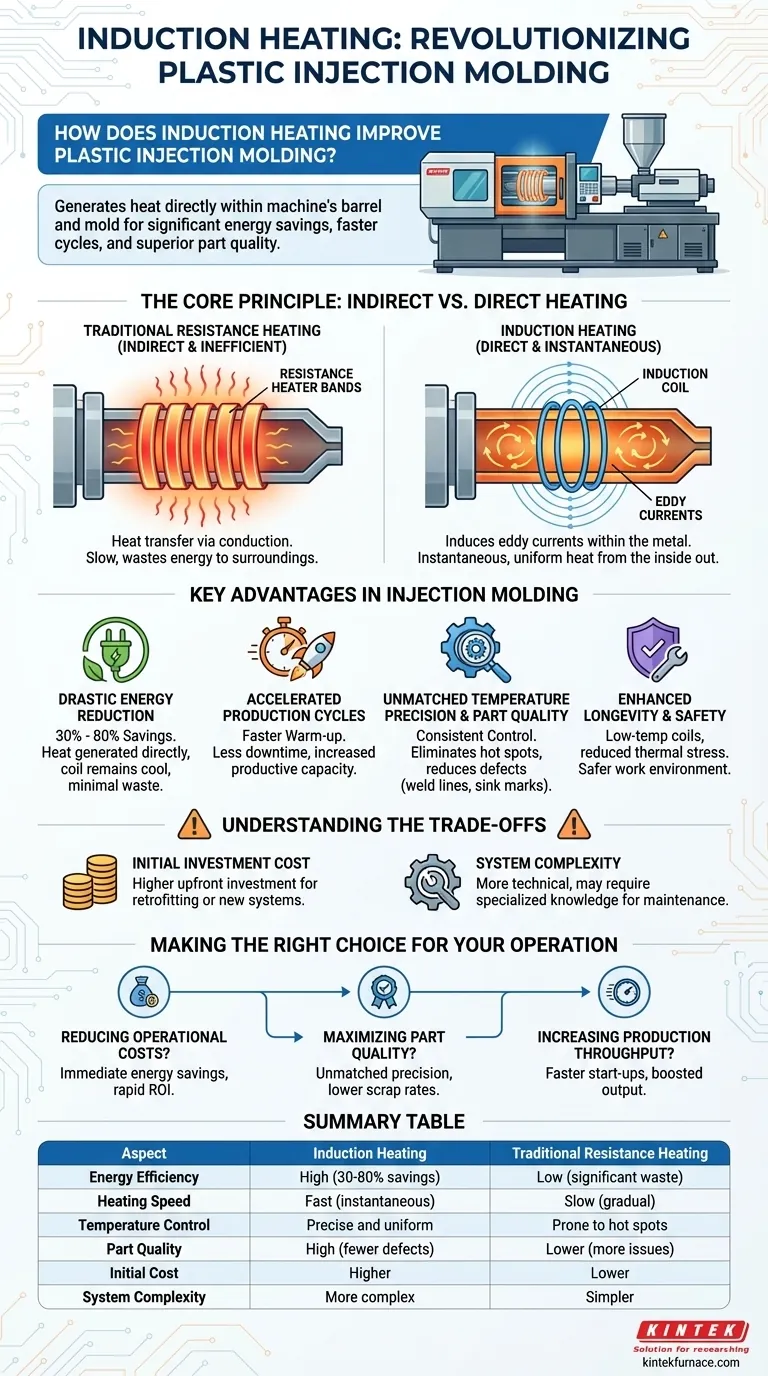

In short, induction heating revolutionizes plastic injection molding by generating heat directly within the metal of the machine's barrel and mold. This approach is fundamentally more efficient than traditional methods, leading to significant energy savings, faster production cycles, and superior, more consistent part quality by eliminating common heating-related defects.

Traditional resistance heaters waste energy by heating the air around the machine's components. Induction heating bypasses this inefficiency by using a magnetic field to make the steel barrel or mold its own heat source, offering a leap forward in speed, control, and operational cost.

The Core Principle: How Induction Heating Differs

To understand the benefits of induction, it's crucial to first recognize the limitations of the traditional heating method it replaces.

Traditional Resistance Heating: Indirect and Inefficient

Most conventional injection molding machines use resistance heater bands. These are simple electrical elements that wrap around the machine's barrel.

These bands work like a stovetop burner: they get hot and then slowly transfer that heat to the steel barrel through conduction. This process is slow and loses a tremendous amount of energy to the surrounding environment.

Induction Heating: Direct and Instantaneous

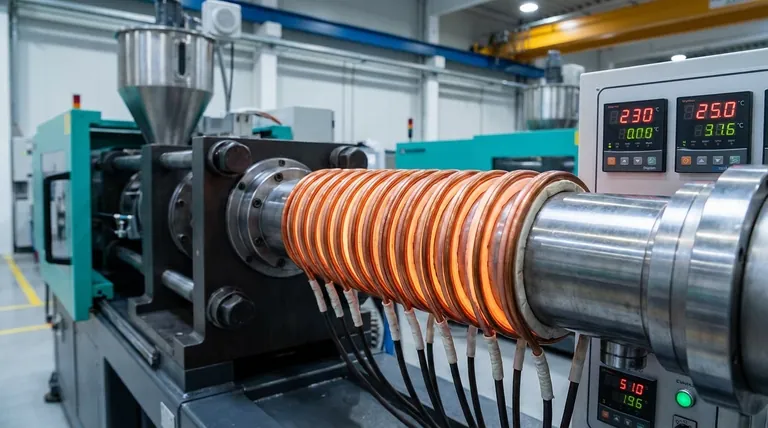

Induction heating uses a high-frequency alternating current passed through a coil. This creates a powerful magnetic field.

When a conductive material like the steel barrel is placed inside this field, the field induces eddy currents directly within the metal. The resistance of the metal to these currents generates precise, instantaneous, and uniform heat from the inside out. The barrel itself becomes the heating element.

Key Advantages in the Injection Molding Process

This shift from indirect to direct heating delivers tangible improvements across the entire production process.

Drastic Reduction in Energy Consumption

Because heat is generated directly where it's needed, very little is wasted. The induction coil itself remains cool and is placed on the outside of thermal insulation, trapping the heat in the barrel.

This efficiency translates to energy savings often ranging from 30% to 80%, significantly lowering operational costs.

Accelerated Production Cycles

Induction systems can bring a machine barrel up to the target temperature much faster than resistance bands.

This reduction in warm-up time means less machine downtime at the start of a shift or during mold changes, directly increasing productive capacity.

Unmatched Temperature Precision and Part Quality

Induction provides extremely precise and consistent temperature control across the entire heating zone.

This eliminates hot spots and temperature fluctuations common with resistance bands. The result is a dramatic reduction in heat-related defects like weld lines, sink marks, and material degradation, leading to higher yields and more reliable final products.

Enhanced Equipment Longevity and Safety

The induction coils operate at a low temperature, reducing thermal stress on both the coils and surrounding components. This leads to a longer service life.

Furthermore, with the hot surfaces covered by insulation, the external temperature of the machine is much lower, creating a safer and more comfortable work environment.

Understanding the Trade-offs

While powerful, induction heating is not a zero-cost upgrade. A clear-eyed assessment requires acknowledging its initial hurdles.

The Initial Investment Cost

The primary barrier to adoption is cost. Retrofitting an existing machine or purchasing a new one with an integrated induction system carries a higher upfront investment compared to traditional resistance heater technology.

System Complexity

Induction systems, with their power supplies and precisely wound coils, are more technically complex than simple heater bands.

While highly reliable, troubleshooting or repair may require more specialized knowledge than is needed for basic resistance heaters.

Application-Specific Design

The efficiency of an induction system is dependent on the coil design relative to the part being heated. While standard barrel heating is straightforward, designing induction systems for complex molds requires careful engineering to ensure uniform heat distribution.

Making the Right Choice for Your Operation

Adopting induction heating is a strategic decision that hinges on your specific production priorities.

- If your primary focus is reducing operational costs: The significant and immediate energy savings from induction heating provide a clear and often rapid return on investment.

- If your primary focus is maximizing part quality and consistency: The precise temperature control of induction is unmatched for producing high-specification parts and reducing scrap rates.

- If your primary focus is increasing production throughput: The rapid start-up times and potential for faster cycles significantly boost a machine's overall output.

By fundamentally changing how heat is generated, induction technology gives manufacturers a powerful tool to improve efficiency, quality, and profitability.

Summary Table:

| Aspect | Induction Heating | Traditional Resistance Heating |

|---|---|---|

| Energy Efficiency | High (30-80% savings) | Low (significant energy waste) |

| Heating Speed | Fast (instantaneous) | Slow (gradual heat transfer) |

| Temperature Control | Precise and uniform | Prone to hot spots and fluctuations |

| Part Quality | High (fewer defects) | Lower (more heat-related issues) |

| Initial Cost | Higher upfront investment | Lower upfront cost |

| System Complexity | More complex | Simpler |

Ready to elevate your plastic injection molding with advanced induction heating solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental and production needs, delivering energy savings, faster cycles, and superior part quality. Contact us today to discuss how we can optimize your process and boost your profitability!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What are the main applications of vacuum hot pressing? Create Dense, Pure Materials for Demanding Industries

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- What is the process of hot pressing? A Guide to Achieving Superior Material Density