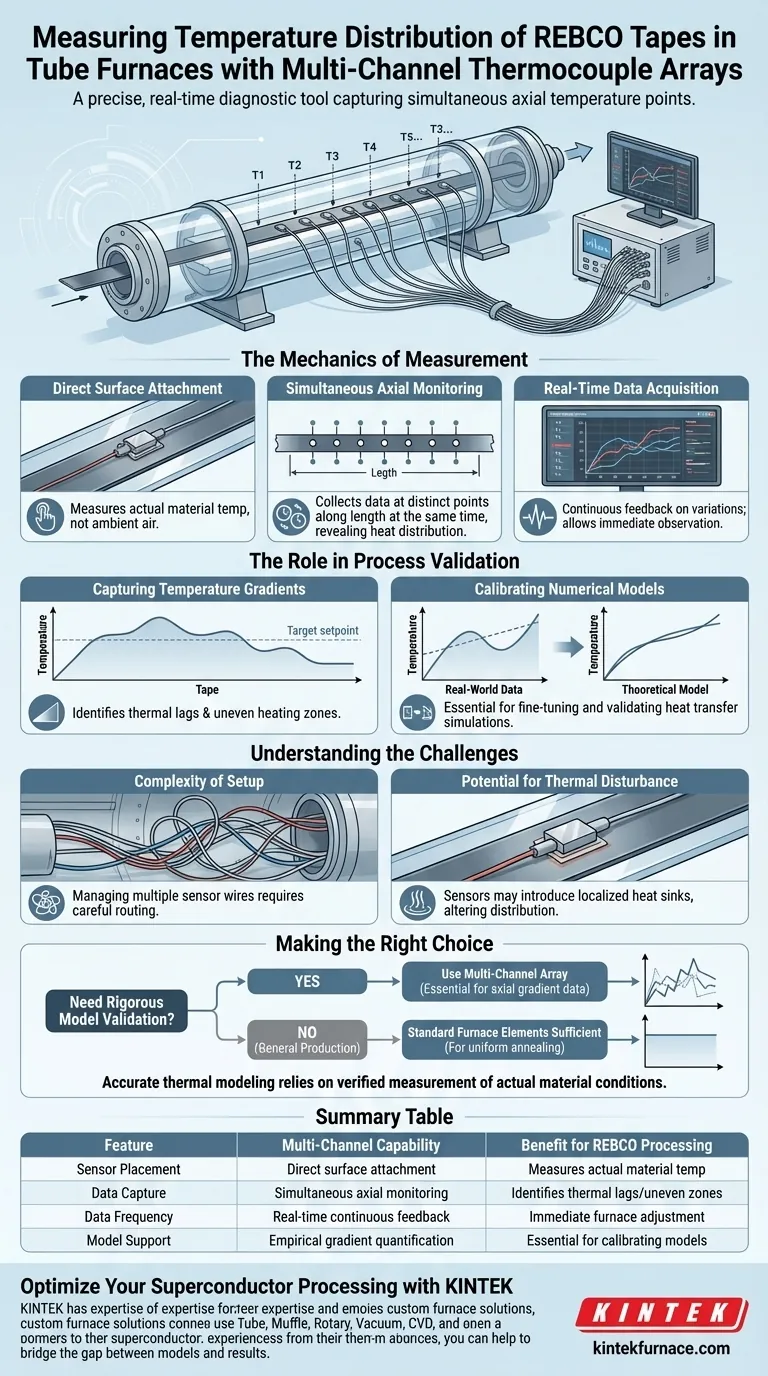

A multi-channel thermocouple array functions as a precise, real-time diagnostic tool. By physically attaching sensors directly to the surface of REBCO tapes, this system captures simultaneous temperature readings at multiple points along the tape’s axial direction. This provides a granular view of thermal conditions that standard single-point furnace sensors cannot offer.

While tube furnaces are designed to create uniform thermal environments, the actual temperature of the material inside often varies. A multi-channel array bridges this gap by providing the specific temperature gradient data required to calibrate and validate heat transfer numerical models.

The Mechanics of Measurement

Direct Surface Attachment

To ensure accuracy, the thermocouples in the array are attached directly to the surface of the REBCO tapes.

This physical contact ensures the sensors measure the actual temperature of the material itself, rather than just the ambient air temperature within the tube.

Simultaneous Axial Monitoring

The array structure allows for data collection at several distinct points along the length (axial direction) of the tape at the exact same time.

This simultaneous monitoring reveals how heat is distributed along the tape, highlighting any uneven heating or thermal lags that occur during the process.

Real-Time Data Acquisition

The system provides continuous, real-time feedback on temperature variations as the furnace operates.

This allows researchers to observe dynamic changes immediately, rather than relying on post-process analysis or theoretical assumptions.

The Role in Process Validation

Capturing Temperature Gradients

Even within a controlled tube furnace, significant temperature gradients can exist along the length of a long tape.

The multi-channel array quantifies these gradients, identifying specific zones where the temperature may deviate from the target setpoint.

Calibrating Numerical Models

The primary strategic value of this data is its use in validating heat transfer numerical models.

By comparing the real-world data from the array against theoretical simulations, researchers can fine-tune their models to ensure they accurately predict the thermal behavior of the REBCO tapes.

Understanding the Challenges

Complexity of Setup

Implementing a multi-channel array increases the physical complexity of the experiment compared to standard furnace operations.

Managing multiple sensor wires within a confined, high-temperature environment requires careful routing to avoid tangling or signal interference.

Potential for Thermal Disturbance

Ideally, measurement tools should not affect the system they are measuring, but physical sensors have mass and thermal conductivity.

Attaching multiple thermocouples to a thin tape can technically introduce small localized heat sinks, potentially altering the very temperature distribution you are trying to measure if not managed correctly.

Making the Right Choice for Your Goal

Whether you need a multi-channel array depends on the precision required by your specific application.

- If your primary focus is rigorous model validation: You must use a multi-channel array to obtain the axial gradient data necessary to prove your numerical simulations are accurate.

- If your primary focus is general production: You may rely on the tube furnace’s standard adjustable heating elements, which are generally sufficient for maintaining uniformity in routine annealing or sintering.

Accurate thermal modeling relies not on assumed uniformity, but on the verified measurement of actual material conditions.

Summary Table:

| Feature | Multi-Channel Array Capability | Benefit for REBCO Processing |

|---|---|---|

| Sensor Placement | Direct surface attachment to tapes | Measures actual material temp vs. ambient air |

| Data Capture | Simultaneous axial monitoring | Identifies thermal lags and uneven heating zones |

| Data Frequency | Real-time continuous feedback | Allows for immediate adjustment of furnace parameters |

| Model Support | Empirical gradient quantification | Essential for calibrating heat transfer numerical models |

Optimize Your Superconductor Processing with KINTEK

Precise thermal control is the backbone of high-performance REBCO tape production. As a leader in laboratory thermal technology, KINTEK provides the advanced equipment necessary to bridge the gap between theoretical models and real-world results.

Backed by expert R&D and manufacturing, we offer high-precision Tube Furnaces, Muffle, Rotary, Vacuum, and CVD systems, all of which are fully customizable to accommodate complex multi-channel sensor arrays and unique diagnostic requirements. Our systems empower researchers to achieve the exact temperature gradients needed for rigorous process validation.

Ready to elevate your thermal precision? Contact us today to discuss your custom furnace needs and see how KINTEK’s engineering expertise can streamline your material development.

Visual Guide

References

- Zili Zhang, Qiuliang Wang. A Tube Furnace Design for the Oxygen Annealing of a REBCO Superconducting Joint. DOI: 10.3390/ma18133053

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

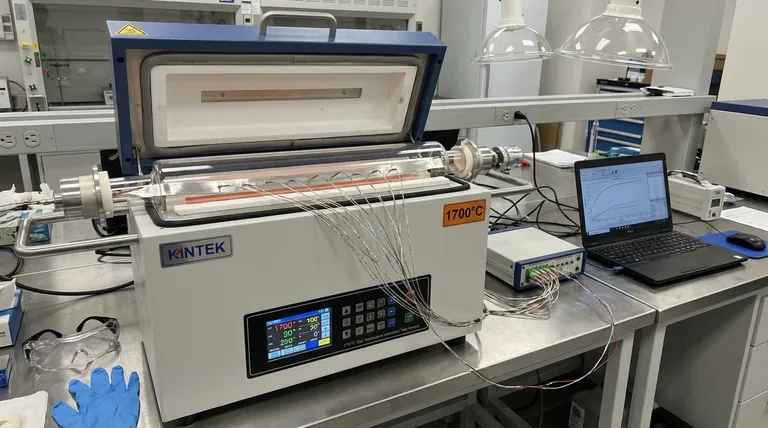

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the primary function of a Drop Tube Furnace? Master Single-Particle Solid Fuel Ignition Analysis

- Why is a tube furnace equipped with an atmosphere control system required for synthesizing h-Zn-Co-O solid solutions?

- Why is vacuum encapsulation in a quartz tube necessary for AFA alloys? Ensure Critical Elemental Integrity

- What is the function of sealed quartz ampoules in Se80In5Te6Sb9 synthesis? Ensure Purity and Precision

- What is the technical significance of using a dual-temperature zone tube furnace for CoTe2 tellurization?

- What function does a tube furnace perform in sintering boron duplex stainless steel? Master High-Precision Results

- What task is performed by industrial high-temperature tube or atmosphere furnaces? Unlock Carbon Aerogel Synthesis

- How does a tube furnace facilitate the activation and shaping of NiCoO2 nanowires? Optimize Your Catalyst Performance