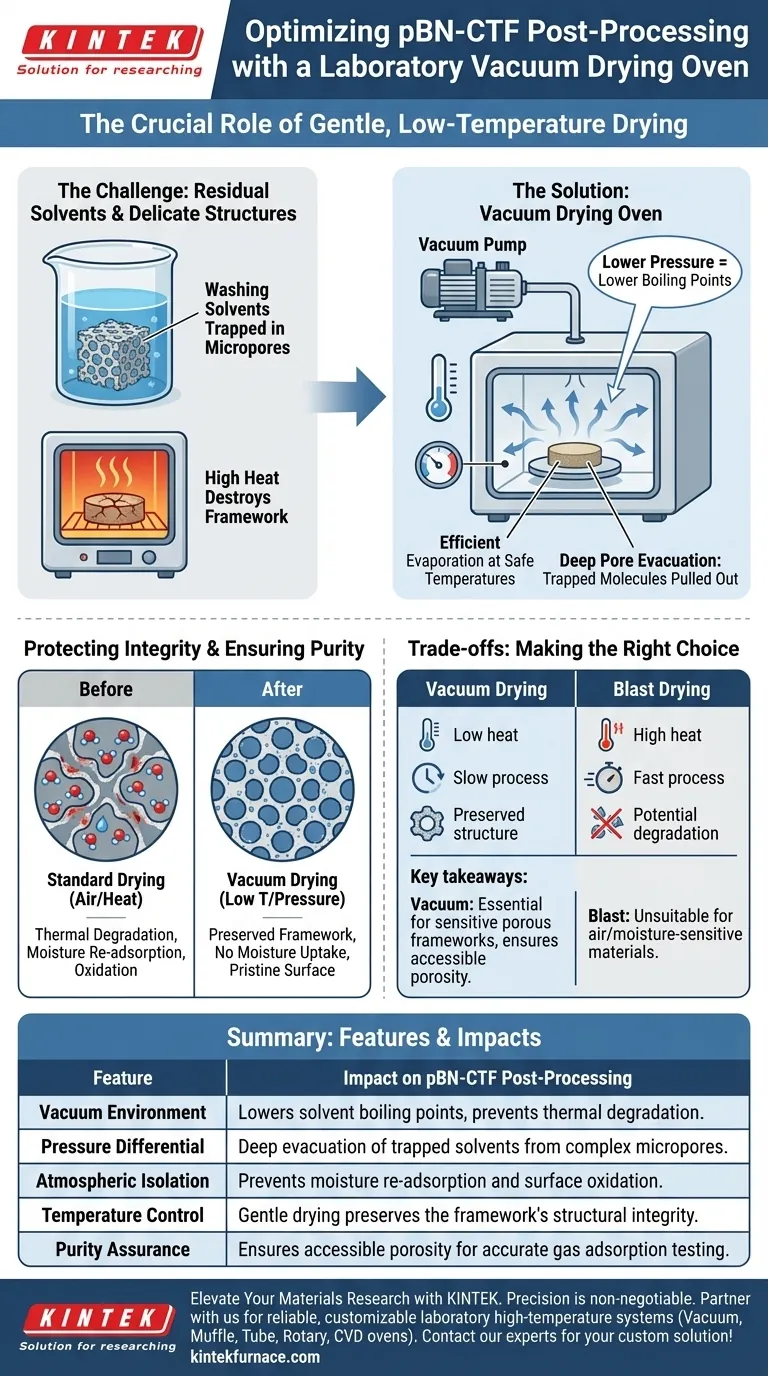

The primary role of a laboratory vacuum drying oven in the post-processing of pBN-CTF (porous boron nitride covalent triazine frameworks) is to ensure the complete removal of washing solvents without damaging the material's delicate structure. By lowering the pressure, the oven reduces the boiling points of residual chloroform, acetone, and methanol, allowing them to evaporate efficiently at safe, low temperatures.

Core Takeaway The vacuum drying oven is essential for clearing the micropores of pBN-CTF products without subjecting the framework to thermal stress. It ensures the material is chemically pure and structurally intact, preventing atmospheric moisture interference that would otherwise compromise subsequent gas adsorption testing.

Mechanisms of Pore Purification

Lowering Solvent Boiling Points

The pBN-CTF synthesis process involves washing with solvents like chloroform, acetone, and methanol. Removing these naturally requires heat, but high temperatures can degrade the material.

The vacuum oven solves this by creating a low-pressure environment. This depression lowers the boiling point of these solvents, causing them to vaporize and exit the material without requiring aggressive thermal energy.

Deep Pore Evacuation

pBN-CTF materials are defined by their complex porous structure. Surface drying methods often leave solvents trapped deep within these micropores.

The vacuum environment creates a pressure differential that actively pulls these trapped solvent molecules out of the framework. This ensures the porosity is fully accessible, rather than blocked by liquid residues.

Protecting Structural Integrity

Preventing Thermal Degradation

Because the vacuum allows for drying at lower temperatures, the thermal stress on the pBN-CTF framework is minimized.

This "gentle" drying helps maintain the structural stability of the porous framework. It prevents the collapse or deformation of pores that can occur when materials are subjected to the higher temperatures required for drying at standard atmospheric pressure.

Avoiding Re-adsorption and Oxidation

Drying a porous material in a standard air oven exposes it to atmospheric moisture and oxygen. pBN-CTF can re-adsorb moisture from the air, which occupies the pores intended for testing.

The vacuum oven isolates the material from the laboratory atmosphere. This prevents moisture uptake and potential oxidation of surface functional groups, ensuring the material is pristine for electrochemical or adsorption analysis.

Understanding the Trade-offs

Vacuum Drying vs. Blast Drying

It is critical to distinguish between a vacuum oven and a high-temperature blast drying oven. A blast oven uses air circulation, which promotes oxidation and is generally unsuitable for materials sensitive to air or moisture.

While blast ovens are effective for physical solidification of robust precipitates, they lack the protective, inert environment required for high-performance porous frameworks like pBN-CTF.

Process Duration vs. Intensity

Vacuum drying is often a slower, more deliberate process compared to high-heat flash drying.

The trade-off is time versus quality; while vacuum drying may take longer to fully evacuate solvents at low temperatures, it is the only method that guarantees the preservation of the material's specific surface area and chemical composition.

Making the Right Choice for Your Goal

When configuring your post-processing parameters for pBN-CTF, consider the specific requirements of your analysis:

- If your primary focus is Gas Adsorption Performance: Prioritize a deep vacuum to ensure every micropore is cleared of solvent and protected from atmospheric moisture entry.

- If your primary focus is Structural Stability: Maintain the lowest possible temperature that still achieves solvent evaporation to prevent thermal stress on the framework.

Effective use of vacuum drying transforms a synthesized powder into a reliable, high-performance functional material.

Summary Table:

| Feature | Impact on pBN-CTF Post-Processing |

|---|---|

| Vacuum Environment | Lowers solvent boiling points to prevent thermal degradation. |

| Pressure Differential | Deep evacuation of trapped solvents from complex micropores. |

| Atmospheric Isolation | Prevents moisture re-adsorption and surface oxidation. |

| Temperature Control | Gentle drying preserves the framework's structural integrity. |

| Purity Assurance | Ensures accessible porosity for accurate gas adsorption testing. |

Elevate Your Materials Research with KINTEK

Precision is non-negotiable when processing advanced porous frameworks like pBN-CTF. At KINTEK, we understand that the integrity of your research depends on the reliability of your equipment. Backed by expert R&D and manufacturing, we offer a comprehensive range of laboratory high-temperature systems—including Vacuum, Muffle, Tube, Rotary, and CVD ovens—all customizable to meet your unique experimental needs.

Don't let solvent residue or thermal stress compromise your results. Partner with KINTEK to ensure your materials achieve their full performance potential.

Contact our experts today to find your custom solution!

Visual Guide

References

- Hanibal Othman, Christoph Janiak. Synthesis and Characterization of Covalent Triazine Frameworks Based on 4,4′-(Phenazine-5,10-diyl)dibenzonitrile and Its Application in CO2/CH4 Separation. DOI: 10.3390/molecules30153110

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Induction Melting Furnace

People Also Ask

- Why is a high vacuum necessary for solar absorbers? Ensure Precise Optical Properties in Thin Film Coating

- What is tempering, and when is it used? Optimize Metal Toughness and Durability

- What role does a microwave chemical reactor play in the synthesis of carbon xerogels? Precision Control & Efficiency

- What is the purpose of using an Argon Stream during activation? Enhance $CO_2$ Adsorption Efficiency

- How does Vacuum Degassing (VD) influence spinel inclusions in heavy rail steel? Controlling Refractory Erosion

- Why is a precision electric heating reactor used for ozone treatment of porous graphene? Unlock Angstrom-Scale Accuracy

- Why does high-phenyl conductive silicone rubber require secondary vulcanization? Essential Stability Guide

- What is the purpose of using an Argon protective atmosphere during the casting of H13 steel? Boost Purity and Strength