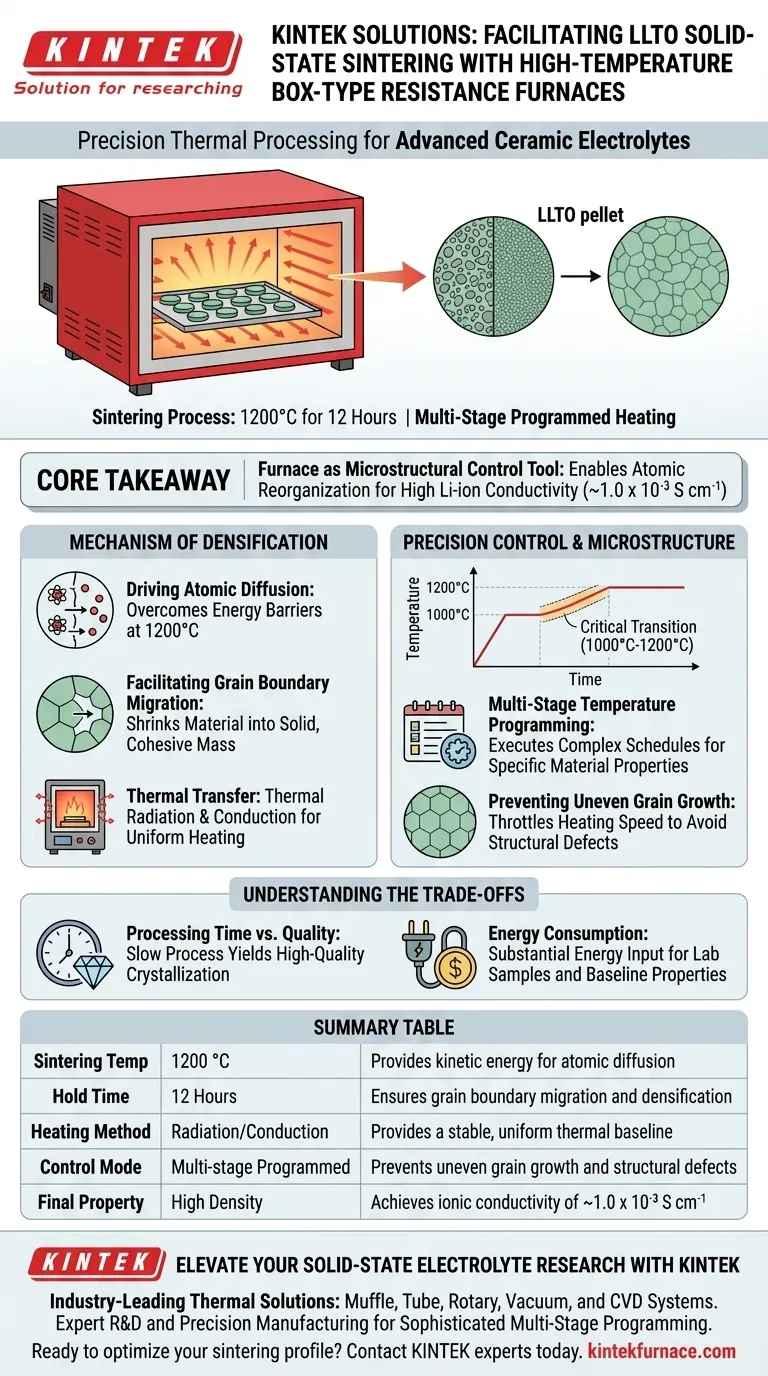

A high-temperature box-type resistance furnace facilitates solid-state sintering of Lithium Lanthanum Titanate (LLTO) by creating a precisely controlled thermal environment that drives atomic diffusion and grain boundary migration. Specifically, it maintains a critical temperature of 1200 °C for 12 hours, utilizing multi-stage programmed heating to prevent uneven grain growth and ensure the formation of a dense, highly conductive crystalline phase.

Core Takeaway The furnace is not merely a heat source; it is a tool for microstructural control. By strictly regulating heating rates and hold times, the furnace enables the atomic reorganization necessary to achieve LLTO’s high lithium-ion conductivity (approximately 1.0 x 10⁻³ S cm⁻¹), transforming pressed "green pellets" into a dense ceramic electrolyte.

The Mechanism of Densification

Driving Atomic Diffusion

The primary function of the furnace is to provide the kinetic energy required for solid-state reactions. By maintaining a constant 1200 °C, the furnace enables atoms within the LLTO structure to overcome energy barriers and diffuse across particle boundaries.

Facilitating Grain Boundary Migration

As diffusion occurs, the furnace’s stable thermal environment promotes grain boundary migration. This process eliminates pores between the original powder particles, effectively shrinking the material into a solid, cohesive mass.

Thermal Transfer Method

Unlike advanced methods such as microwave sintering, a box-type resistance furnace relies on thermal radiation and conduction. This traditional approach ensures uniform heating from the outside in, providing a stable baseline for densification.

Precision Control and Microstructure

Multi-Stage Temperature Programming

The critical advantage of this furnace type is the ability to execute complex heating schedules. It does not simply ramp up to the target temperature linearly; it follows a programmed curve designed for the specific material properties of LLTO.

Controlling the Critical Transition

A specific feature often employed is slowing the heating rate during the transition from 1000 °C to 1200 °C. This specific temperature window is volatile for crystal formation.

Preventing Uneven Grain Growth

By throttling the heating speed in this upper range, the furnace prevents grains from growing too rapidly or unevenly. Uncontrolled growth leads to structural defects that impede lithium-ion movement, drastically reducing the electrolyte's performance.

Understanding the Trade-offs

Processing Time vs. Quality

The solid-state sintering process in a box furnace is inherently slow, often requiring a 12-hour hold time plus ramp-up and cool-down periods. While this yields high-quality crystallization, it is significantly more time-consuming than spark plasma or microwave sintering techniques.

Energy Consumption

Maintaing 1200 °C for extended durations requires substantial energy input. This makes the box-type resistance furnace excellent for establishing baseline material properties and high-quality lab samples, but potentially costly for high-throughput industrial manufacturing without optimization.

Making the Right Choice for Your Goal

To maximize the effectiveness of your sintering process, consider the following outcome-based recommendations:

- If your primary focus is maximizing ionic conductivity: Prioritize the multi-stage programming capability, specifically reducing the ramp rate between 1000 °C and 1200 °C to ensure uniform grain structure.

- If your primary focus is comparative research: Use the box furnace as a control group, as its thermal radiation mechanism provides a standard baseline to compare against novel sintering techniques like microwave heating.

Success in LLTO sintering depends less on achieving high heat, and more on the precision of the thermal profile during the final densification stages.

Summary Table:

| Parameter | Specification | Impact on LLTO Sintering |

|---|---|---|

| Sintering Temp | 1200 °C | Provides kinetic energy for atomic diffusion |

| Hold Time | 12 Hours | Ensures grain boundary migration and densification |

| Heating Method | Radiation/Conduction | Provides a stable, uniform thermal baseline |

| Control Mode | Multi-stage Programmed | Prevents uneven grain growth and structural defects |

| Final Property | High Density | Achieves ionic conductivity of ~1.0 x 10⁻³ S cm⁻¹ |

Elevate Your Solid-State Electrolyte Research with KINTEK

Precision is the difference between a failed pellet and a high-conductivity electrolyte. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered for materials science researchers.

Backed by expert R&D and precision manufacturing, our furnaces offer the sophisticated multi-stage programming required to control the critical 1000°C–1200°C transition in LLTO sintering. Whether you need a standard lab furnace or a fully customizable high-temperature system, we deliver the stability your microstructure demands.

Ready to optimize your sintering profile? Contact KINTEK experts today to discuss your unique research requirements.

Visual Guide

References

- Pei‐Yin Chen, Sheng‐Heng Chung. A solid-state electrolyte for electrochemical lithium–sulfur cells. DOI: 10.1039/d3ra05937e

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a laboratory muffle furnace contribute to the thermal processing of Ti-Zr-Nb alloy sheets?

- What are the safety precautions when connecting power to a new muffle furnace? Ensure Safe Setup for Your Lab

- What is the function of a muffle furnace during catalyst calcination? Master Biomass-to-Catalyst Transformation

- What role does a muffle furnace play in the curing process of GaN and TiO2? Optimize Your Photoanode Sintering

- How does the position of gas inlets in a muffle furnace affect the temperature distribution? Master Thermal Uniformity

- What is the function of a muffle furnace in the preparation of phosphate glass raw materials? Expert Insights

- What features make muffle furnaces easy to operate? Discover Key Ease-of-Use Features

- What role does a high-temperature muffle furnace play in the preparation of acid-activated clay? Key Thermal Mechanisms