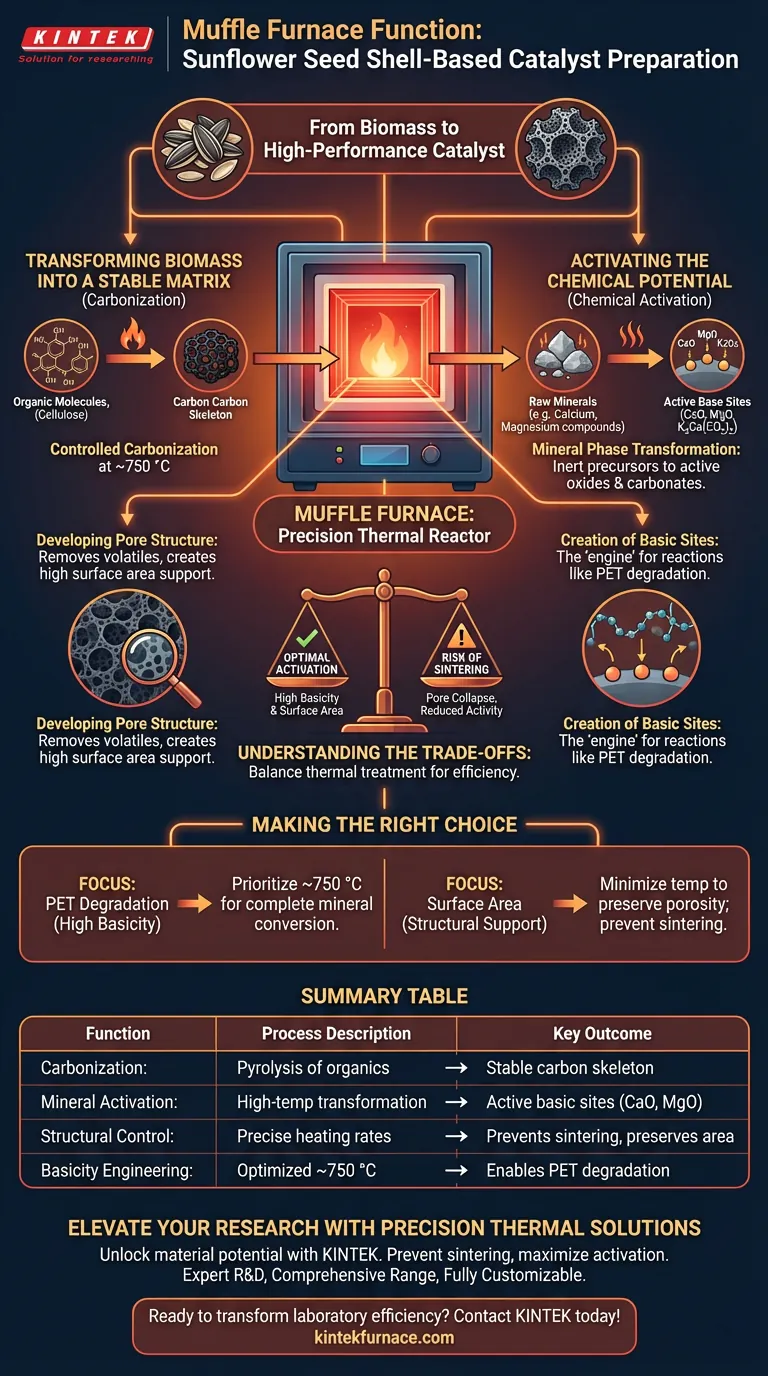

The muffle furnace acts as a precision thermal reactor that facilitates the simultaneous carbonization of the sunflower seed shell matrix and the chemical activation of its inherent mineral components.

Specifically, it provides a controlled high-temperature environment (typically around 750 °C) that converts the organic biomass into a stable carbon support while transforming natural mineral elements into highly reactive metal oxides and carbonates, such as Calcium Oxide (CaO) and Magnesium Oxide (MgO).

Core Insight: The muffle furnace does not simply burn the biomass; it engineers a phase change. It transitions the sunflower seed shell from agricultural waste into a complex catalytic composite, activating the strong base sites required to degrade resistant materials like waste Polyethylene Terephthalate (PET).

Transforming Biomass into a Stable Matrix

The first critical function of the muffle furnace is to manage the physical structure of the catalyst through pyrolysis.

Controlled Carbonization

At high temperatures, the furnace drives the thermal decomposition of the organic components (lignin, cellulose, and hemicellulose) within the sunflower seed shells.

This process removes volatile organic compounds and leaves behind a porous, carbonaceous skeleton. This carbon backbone serves as the structural support for the active catalytic sites.

Developing Pore Structure

By precisely controlling the heating rate and duration, the furnace ensures the removal of organic matter without collapsing the structure.

This results in a material with a high specific surface area, which is essential for allowing reactants to access the active sites during the catalytic process.

Activating the Chemical Potential

While carbonization addresses the structure, the furnace’s most vital role is the chemical transformation of the inorganic minerals found naturally in the shells.

Mineral Phase Transformation

Sunflower seed shells contain inherent minerals that are catalytically inert in their raw form. The high thermal energy provided by the muffle furnace (e.g., 750 °C) triggers a phase transformation.

This heat converts precursors into active metal oxides and carbonates, specifically generating components like Calcium Oxide (CaO), Magnesium Oxide (MgO), and Potassium Calcium Carbonate (K2Ca(CO3)2).

Creation of Basic Sites

These newly formed oxides are not passive fillers; they function as strong base sites.

In the context of sunflower seed shell catalysts, these basic sites are the "engine" that drives chemical reactions, such as the depolymerization of PET plastics. Without the high-temperature treatment of the muffle furnace, these minerals would remain inactive and ineffective.

Understanding the Trade-offs

While the muffle furnace is essential for activation, improper management of the thermal environment can degrade catalyst performance.

The Risk of Sintering

Higher temperatures generally increase the conversion of minerals into their active oxide forms. However, excessive heat or prolonged exposure can lead to sintering.

Sintering causes the particles to fuse together, collapsing the pore structure and drastically reducing the surface area. This limits the catalyst's efficiency, as reactants can no longer reach the active sites.

Energy vs. Activity Balance

Operating at 750 °C requires significant energy input. You must balance the cost of this thermal treatment against the resulting catalytic activity.

There is often a diminishing return where further temperature increases yield only marginal gains in catalytic basicity while significantly increasing energy costs and the risk of structural degradation.

Making the Right Choice for Your Goal

When configuring your muffle furnace for catalyst preparation, your parameters should reflect your specific end-goal.

- If your primary focus is PET Degradation (High Basicity): Prioritize higher temperatures (around 750 °C) to ensure the complete conversion of Calcium and Magnesium into their highly active oxide forms, providing the strong base sites needed for this reaction.

- If your primary focus is Surface Area (Structural Support): Be cautious of exceeding necessary temperatures; aim for the lowest temperature that achieves carbonization to preserve the maximum porosity of the carbon support and prevent sintering.

Ultimately, the muffle furnace is the tool that defines the identity of your material, determining whether it remains a simple carbon powder or becomes a high-performance chemical catalyst.

Summary Table:

| Function | Process Description | Key Outcome |

|---|---|---|

| Carbonization | Pyrolysis of lignin, cellulose, and hemicellulose | Creates a stable, porous carbon skeleton |

| Mineral Activation | High-temp transformation of inherent minerals | Generates active basic sites (CaO, MgO) |

| Structural Control | Precise management of heating rates | Prevents sintering and preserves surface area |

| Basicity Engineering | Optimized thermal environment at ~750 °C | Enables effective degradation of materials like PET |

Elevate Your Research with Precision Thermal Solutions

Unlock the full potential of your material engineering with KINTEK. Whether you are developing biomass-derived catalysts or advanced composites, our high-performance thermal systems provide the exact temperature uniformity and control required to prevent sintering and maximize chemical activation.

Why Choose KINTEK?

- Expert R&D & Manufacturing: Decades of experience in lab-scale and industrial thermal processing.

- Comprehensive Range: We offer Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for diverse applications.

- Fully Customizable: Systems designed to meet your unique temperature, atmosphere, and structural needs.

Ready to transform your laboratory efficiency? Contact us today to find the perfect furnace for your application!

Visual Guide

References

- Linlin Zhao, A. Washbrook. Optimization of operating conditions for the catalytic alcoholysis of waste PET for the synthesis of BHET by sunflower seed husk matrix materials. DOI: 10.1039/d4ra07206e

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of a muffle furnace in sintering nickel ferrite? Optimize Densification and Magnetic Performance

- What role does a laboratory muffle furnace play in the ash analysis of plant samples? Achieve Clean Mineral Isolation

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength

- How does a high-temperature Muffle Furnace facilitate the conversion of precursors into spinel-type NiCo2O4?

- What customization options are available for muffle furnaces? Tailor Your Furnace for Peak Performance

- What are the general applications of a muffle furnace? Ideal for Ashing, Sintering, and Heat Treatment

- What is the primary function of a laboratory oven during the initial processing of geopolymer samples? Expert Guide

- What is the function of an industrial muffle furnace in g-C3N4 synthesis? Optimize Your Thermal Polymerization