At its core, a muffle furnace is a high-temperature oven used for a wide range of material processing and testing applications where uniform heat is critical. Its primary function is to heat a sample within a chamber, or "muffle," that is isolated from direct contact with the heating elements, ensuring both thermal consistency and reduced contamination. This makes it a staple in laboratories, research institutes, and industrial settings for tasks ranging from ashing samples to sintering ceramics.

A muffle furnace excels at providing precise, high-temperature heat in a standard air atmosphere. Its value lies in the "muffle" design, which separates the sample from the heating source, making it ideal for processes where uniform heating is more critical than maintaining a specialized (e.g., vacuum or inert gas) environment.

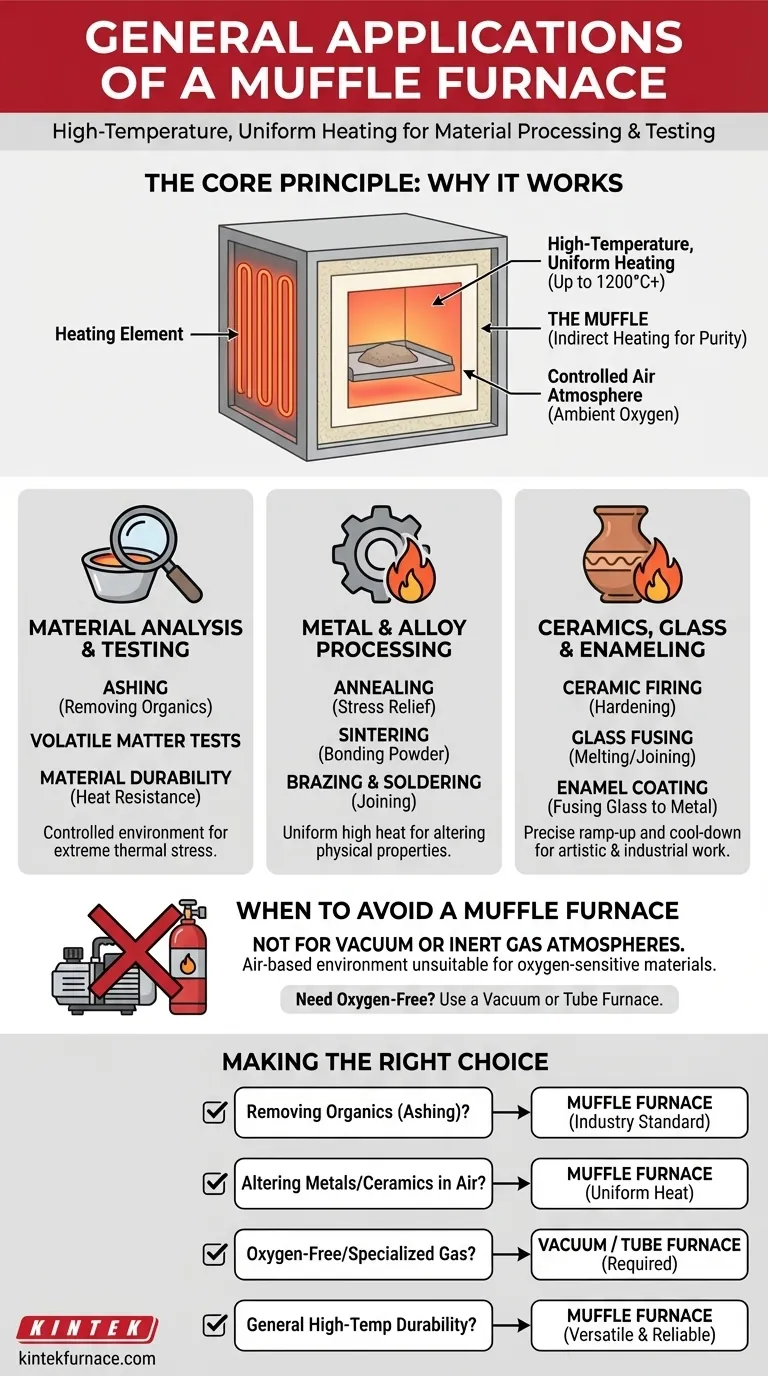

The Core Principle: Why a Muffle Furnace Works

To understand its applications, you must first understand its fundamental design. A muffle furnace is not just a simple oven; its effectiveness comes from a few key characteristics.

High-Temperature, Uniform Heating

A primary feature of a muffle furnace is its ability to reach and maintain very high temperatures, often exceeding 1200°C (2192°F). The insulated chamber is designed to distribute this heat evenly, eliminating hot spots and ensuring the entire sample experiences a consistent thermal profile.

The "Muffle": Indirect Heating for Purity

The defining component is the muffle itself—a refractory ceramic chamber that contains the sample. The heating elements are positioned on the outside of this chamber. This indirect heating method prevents the material being processed from being contaminated by flakes or particles from the heating elements, which is crucial for many analytical and treatment processes.

Controlled Air Atmosphere

Unless specifically modified, a standard muffle furnace operates in an ambient air atmosphere. The oxygen present in the air is essential for certain applications, most notably ashing, where complete combustion of organic material is the goal.

Primary Applications by Category

The unique design of a muffle furnace makes it the ideal tool for several distinct categories of work.

Material Analysis and Testing

This is one of the most common uses in a laboratory setting. The furnace provides a controlled environment to test how materials behave under extreme thermal stress.

Key applications include:

- Ashing: Burning off all organic compounds from a sample to accurately measure the weight of the inorganic residue (ash). This is fundamental for gravimetric analysis and determining the composition of materials like food, polymers, and coal.

- Volatile Matter Tests: Heating a sample to a specific temperature to measure the loss of mass due to the release of volatile components.

- Material Durability: Testing the heat resistance and structural integrity of materials like cements, soils, aggregates, and engineered composites.

Metal and Alloy Processing

The uniform, high heat of a muffle furnace is perfect for altering the physical properties of metals.

Key applications include:

- Annealing: Heating a metal and allowing it to cool slowly to remove internal stresses and increase its ductility.

- Sintering: Heating powdered materials (metal or ceramic) below their melting point until their particles bond together, forming a solid piece.

- Brazing & Soldering: Joining metal components using a filler metal, which requires precise temperature control.

Ceramics, Glass, and Enameling

The furnace's ability to slowly ramp up to high temperatures and cool down in a controlled manner is critical for artistic and industrial ceramic and glass work.

Key applications include:

- Ceramic Firing: Hardening clay and glazes to create finished ceramic parts.

- Glass Fusing: Heating pieces of glass until they melt and fuse together.

- Enamel Coating: Fusing a layer of powdered glass onto a substrate, typically metal, to create a durable, protective, or decorative coating.

Understanding the Trade-offs: When to Avoid a Muffle Furnace

While versatile, a muffle furnace is not the right tool for every high-temperature job. Understanding its limitations is key to making the right choice.

Not for Vacuum or Inert Gas Atmospheres

The most significant limitation is its air-based environment. If your material is sensitive to oxygen or requires processing in a vacuum or under a specific gas (like argon or nitrogen), a muffle furnace is unsuitable. In those cases, a vacuum furnace or a tube furnace with gas flow capabilities is necessary.

Purity vs. Process Requirement

While the muffle protects the sample from the heating elements, it does not protect it from the air within the chamber. For processes where any oxidation is detrimental, even if a full vacuum is not needed, a muffle furnace may not be the best choice.

Making the Right Choice for Your Application

Use this guide to determine if a muffle furnace fits your objective.

- If your primary focus is removing organic material for analysis (Ashing): A muffle furnace is the industry-standard tool due to its ability to achieve high, consistent temperatures in an oxygen-rich environment.

- If your primary focus is altering the properties of metals or ceramics (Heat Treatment/Sintering): A muffle furnace provides the necessary uniform heat, but only if your material is not reactive with air at high temperatures.

- If your primary focus requires an oxygen-free or specialized gas environment: You must use a vacuum furnace or a tube furnace, as a standard muffle furnace is fundamentally incompatible with this need.

- If your primary focus is general high-temperature durability testing: The muffle furnace is a versatile and reliable choice for evaluating how materials hold up under extreme heat in a normal atmosphere.

Understanding these core functions and limitations ensures you select the most effective thermal processing tool for your specific objective.

Summary Table:

| Application Category | Key Uses |

|---|---|

| Material Analysis | Ashing, Volatile Matter Tests, Durability Testing |

| Metal Processing | Annealing, Sintering, Brazing & Soldering |

| Ceramics & Glass | Ceramic Firing, Glass Fusing, Enamel Coating |

Ready to enhance your laboratory's capabilities with a high-temperature furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs precisely. Contact us today to discuss how our furnaces can optimize your material processing and testing!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation