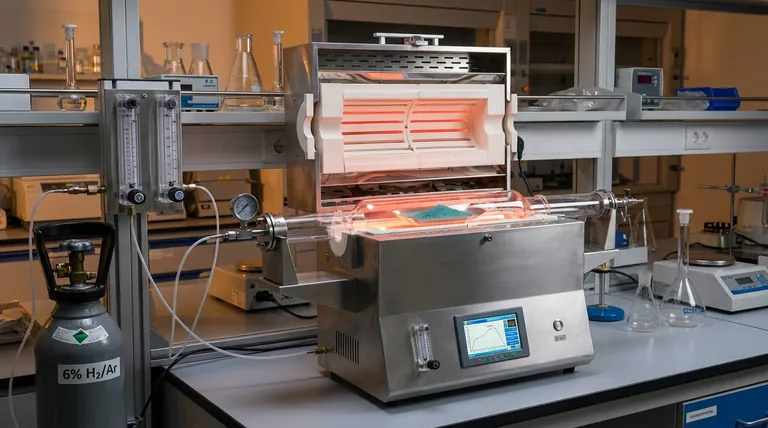

A high-precision tube furnace serves as the critical control vessel for the reduction of Cu/ZIF-8 catalysts, enabling the transformation of copper ions into metallic clusters without destroying the catalyst's support structure. It achieves this by maintaining a strictly controlled reducing atmosphere (specifically 6% H2/Ar) and a precise, programmed heating rate of approximately 10 K/min.

Core Insight: The primary function of the tube furnace in this application is protection through precision. It governs the reduction speed to ensure Cu2+ ions convert to metallic copper steady, preventing the thermal shock that leads to pore collapse or the clumping of particles (sintering) within the delicate ZIF-8 framework.

Precise Thermal Regulation

The most significant contribution of the tube furnace is its ability to execute a programmed temperature profile with high accuracy.

Controlled Heating Rates

For Cu/ZIF-8, the furnace is typically programmed to heat at a rate of approximately 10 K/min. This specific ramp rate is not arbitrary; it allows for a steady, controlled input of thermal energy.

Preventing Thermal Shock

By avoiding instantaneous high temperatures, the furnace prevents thermal shock to the material. This steady rise in temperature is essential for managing the kinetics of the reduction reaction.

Managing the Reaction Atmosphere

Beyond temperature, the tube furnace acts as a sealed environmental chamber that dictates the chemical interactions occurring at the catalyst surface.

Strict Atmosphere Control

The furnace maintains a specific reducing environment, such as a 6% H2/Ar mixture. The sealing precision of the furnace ensures that this ratio remains constant and that no external oxygen compromises the process.

Regulating Oxidation States

This controlled environment facilitates the steady reduction of Cu2+ species into tiny metallic Cu clusters. The furnace ensures the copper is reduced to the correct metallic state without over-reduction or re-oxidation.

Preserving Structural Integrity

The ultimate goal of using high-precision equipment is to maintain the architecture of the ZIF-8 support, which is known for its porosity but can be thermally fragile.

Preventing Pore Collapse

ZIF-8 frameworks are susceptible to degradation at high temperatures. The precision control of the furnace ensures the process stays within a thermal window that allows reduction to occur without causing the framework pores to collapse.

Avoiding Particle Sintering

If the temperature spikes or the reduction happens too violently, copper particles tend to migrate and clump together (sintering). The tube furnace's stability ensures the copper remains as highly dispersed, tiny clusters, which is vital for catalytic activity.

Understanding the Trade-offs

While high-precision tube furnaces offer superior control, it is important to understand the operational boundaries involved in this process.

Throughput vs. Precision

The requirement for a slow, controlled heating rate (e.g., 10 K/min) inherently limits the speed of production. This process cannot be rushed; attempting to accelerate the heating rate to increase throughput often results in the destruction of the ZIF-8 lattice.

Sensitivity to Gas Composition

The process relies heavily on the exact composition of the reducing gas (H2/Ar). Slight deviations in gas flow or a breach in the furnace seal can lead to incomplete reduction or the introduction of impurities, rendering the catalyst ineffective.

Making the Right Choice for Your Goal

To maximize the effectiveness of your Cu/ZIF-8 catalyst synthesis, align your furnace parameters with your specific performance objectives.

- If your primary focus is Maximizing Active Sites: Prioritize the accuracy of the heating ramp rate (10 K/min) to ensure the copper forms tiny, dispersed clusters rather than large particles.

- If your primary focus is Framework Stability: Focus on the upper temperature limit and gas flow consistency to prevent the structural collapse of the ZIF-8 pores during reduction.

Success in reducing Cu/ZIF-8 relies not just on reaching a high temperature, but on the disciplined, programmed journey to get there.

Summary Table:

| Parameter | Specification/Requirement | Impact on Cu/ZIF-8 Catalyst |

|---|---|---|

| Heating Rate | ~10 K/min | Prevents thermal shock and lattice destruction |

| Atmosphere | 6% H2/Ar mixture | Facilitates steady reduction and prevents oxidation |

| Temperature Control | High-precision programming | Avoids particle sintering and maintains dispersion |

| Structural Goal | Pore preservation | Ensures high porosity and catalytic active sites |

Elevate Your Catalyst Synthesis with KINTEK

Precise thermal processing is the difference between a high-performance catalyst and a collapsed framework. At KINTEK, we understand that success lies in the discipline of the thermal journey.

Backed by expert R&D and world-class manufacturing, KINTEK offers advanced Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research or production needs. Whether you are reducing delicate metal-organic frameworks (MOFs) like ZIF-8 or developing next-generation materials, our high-precision furnaces provide the atmospheric integrity and ramp-rate accuracy your work demands.

Ready to optimize your reduction process? Contact our technical experts today to find the perfect high-temperature solution for your lab.

References

- Vijay K. Velisoju, Pedro Castaño. Copper nanoparticles encapsulated in zeolitic imidazolate framework-8 as a stable and selective CO2 hydrogenation catalyst. DOI: 10.1038/s41467-024-46388-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a horizontal tube furnace ensure experimental safety and accuracy during the thermal dehydrogenation of Ca(AlH4)2?

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What are the technical requirements for an industrial tube furnace for selective chlorination? Reach 1873 K with Precision

- What role does a high-temperature tube furnace play in graphite recycling? Restoring Purity and Structure

- What is the primary function of a high-temperature tube furnace for Ce-MOF to CeO2 conversion? Guide to Precision Nano-Engineering

- Why are tube furnaces considered essential for scientific research? Unlock Precise High-Temperature Control

- How does a fixed-bed reactor system simulate complex flue gas environments? Optimize Mercury Adsorption Testing

- What are the maximum temperature capabilities for each zone in a three-zone split tube furnace? Explore Key Ranges and Control