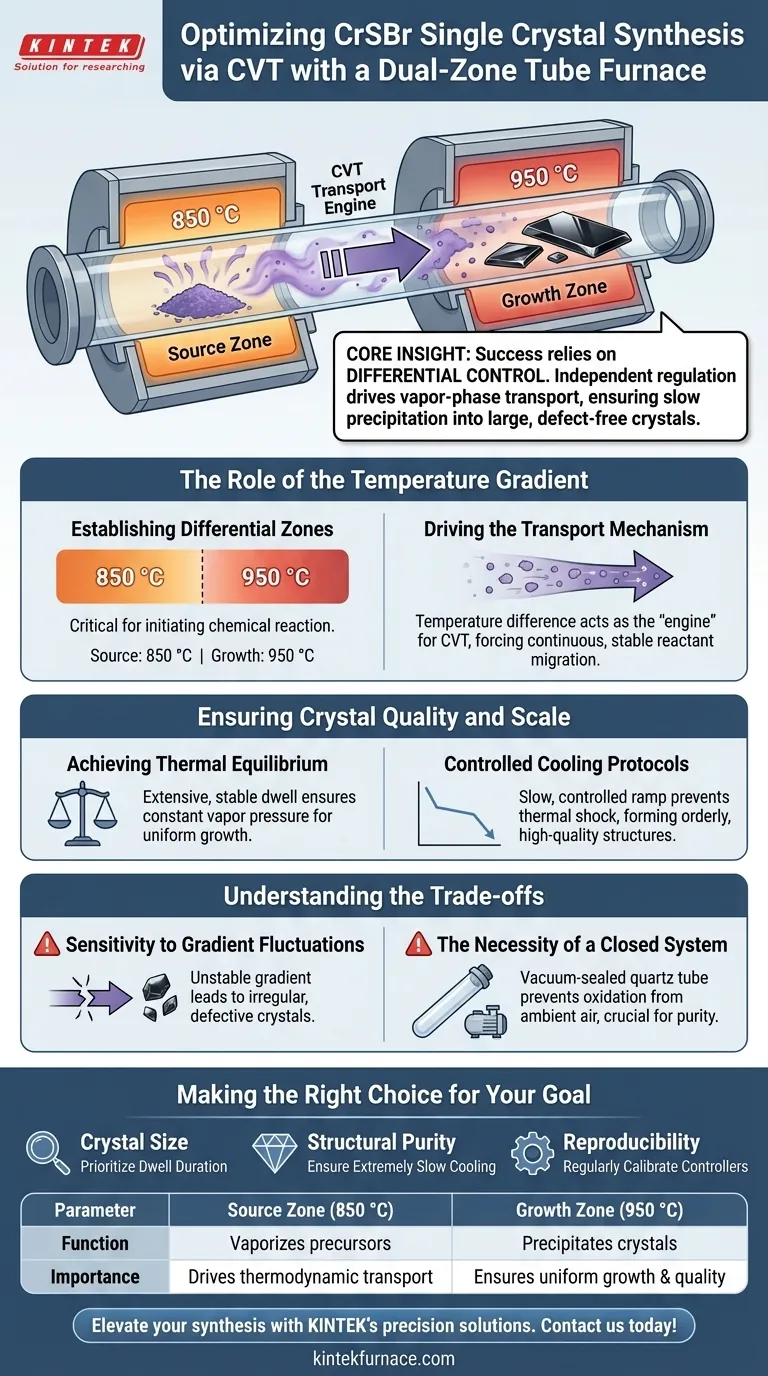

A dual-zone tube furnace facilitates the synthesis of CrSBr single crystals by establishing a precise, stable temperature gradient essential for Chemical Vapor Transport (CVT). By maintaining the source zone at 850 °C and the growth zone at 950 °C, the furnace creates the thermodynamic conditions necessary to transport reactants within a sealed quartz tube, resulting in the crystallization of high-quality materials.

Core Insight: The success of CrSBr synthesis relies not just on high heat, but on the differential control of that heat. The dual-zone furnace allows for independent temperature regulation at both ends of the reaction tube, driving the transport of vapor-phase reactants and ensuring they precipitate slowly into large-scale, defect-free single crystals.

The Role of the Temperature Gradient

Establishing Differential Zones

The fundamental mechanism of the dual-zone furnace is its ability to create two distinct thermal environments within a single system.

For CrSBr synthesis, the source zone is heated to 850 °C, while the growth zone is maintained at a higher temperature of 950 °C. This specific differential is critical for initiating the chemical reaction required for this particular crystal.

Driving the Transport Mechanism

The temperature difference between these two zones acts as the "engine" for the Chemical Vapor Transport (CVT) process.

It forces the reactants to migrate through the sealed quartz tube. The furnace ensures this migration is continuous and stable, moving materials from the source area to the growth area where crystallization occurs.

Ensuring Crystal Quality and Scale

Achieving Thermal Equilibrium

Synthesis is not instantaneous; the furnace must maintain the target temperatures (850 °C and 950 °C) with extreme stability.

The system keeps the reactants in thermal equilibrium for an extended period. This stability is required to ensure the vapor pressure inside the tube remains constant, allowing for uniform crystal growth rather than rapid, chaotic precipitation.

Controlled Cooling Protocols

The growth process does not end when the heating stops. The furnace manages the cooling phase with equal precision.

By executing a controlled cooling ramp after the dwell period, the furnace prevents thermal shock. This slow reduction in temperature allows the CrSBr crystals to form orderly structures, resulting in high-quality, large-scale single crystals.

Understanding the Trade-offs

Sensitivity to Gradient Fluctuations

The primary risk in using a dual-zone furnace is the stability of the gradient.

If the independent controllers fail to maintain the precise separation between 850 °C and 950 °C, the transport rate may fluctuate. This can lead to crystals that are small, irregular, or riddled with structural defects.

The Necessity of a Closed System

The furnace controls the heat, but the quartz tube controls the atmosphere.

As noted in the broader context of CVT, the furnace must operate on a vacuum-sealed tube to prevent oxidation. If the tube seal is compromised, even perfect temperature control by the furnace cannot prevent the contamination of the CrSBr crystals by ambient air.

Making the Right Choice for Your Goal

To maximize the effectiveness of a dual-zone furnace for CrSBr synthesis, consider the following strategic priorities:

- If your primary focus is Crystal Size: Prioritize the duration of the thermal equilibrium phase; a longer stable period allows for larger, more substantial growth.

- If your primary focus is Structural Purity: Ensure the furnace's cooling rate is programmed to be extremely slow to prevent defects during the solidification phase.

- If your primary focus is Reproducibility: Regularly calibrate the independent temperature controllers to ensure the 850 °C / 950 °C gradient remains exact across multiple runs.

Ultimate success in CrSBr growth comes from the precise orchestration of temperature differentials, vacuum integrity, and patience during the cooling phase.

Summary Table:

| Parameter | Source Zone (Reactants) | Growth Zone (Crystallization) | Importance for CrSBr |

|---|---|---|---|

| Temperature Setting | 850 °C | 950 °C | Drives the thermodynamic transport mechanism |

| Thermal Stability | High Precision | High Precision | Ensures constant vapor pressure and uniform growth |

| Function | Vaporizes precursors | Precipitates crystals | Controls the migration of reactants through the tube |

| Cooling Phase | Controlled Ramp | Controlled Ramp | Prevents thermal shock and structural defects |

Elevate your material synthesis with KINTEK’s precision thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers advanced Dual-Zone Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of CrSBr single crystal growth and other lab high-temperature applications. Contact us today to find the perfect furnace for your research needs!

Visual Guide

References

- Weibin Shi, Shouguo Wang. Controllable Antiferromagnetic to Ferromagnetic Transition of CrSBr by Organic Cation Intercalation. DOI: 10.1002/aelm.202500125

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Can an alumina tube furnace be used for controlled atmosphere experiments? Yes, for precise high-temperature control.

- What specific process environment does a tube furnace provide for PtTe2 tellurization? Achieve High Crystallinity

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- Why is a tube furnace required during the synthesis of phosphorus-doped nickel catalysts using high-purity nitrogen?

- What is the primary purpose of using a Quartz Tube Furnace for MoS2 annealing? Unlock High Electrical Performance

- What role does a tube furnace play in the high-temperature heat treatment of vermiculite? Precision Control Expert

- What is the purpose of using forming gas (N2/H2) in a tube furnace? Achieve High-Purity Cr3+-Activated LiScO2 Phosphors

- How does the temperature control program of a tube furnace affect NiSSe nanocrystal formation? Optimize Your Synthesis