Yes, an alumina tube furnace is an excellent choice for controlled atmosphere experiments. In fact, this capability is a primary reason for its widespread use in advanced materials research and processing. These furnaces are specifically designed to create high-temperature, chemically inert environments that can be precisely managed with a vacuum or a continuous flow of a specific gas.

While an alumina tube furnace is purpose-built for controlled atmosphere work, achieving reliable and repeatable results depends entirely on understanding its operational limits. Success hinges on proper atmospheric sealing and careful management of heating and cooling rates to prevent thermal shock to the ceramic tube.

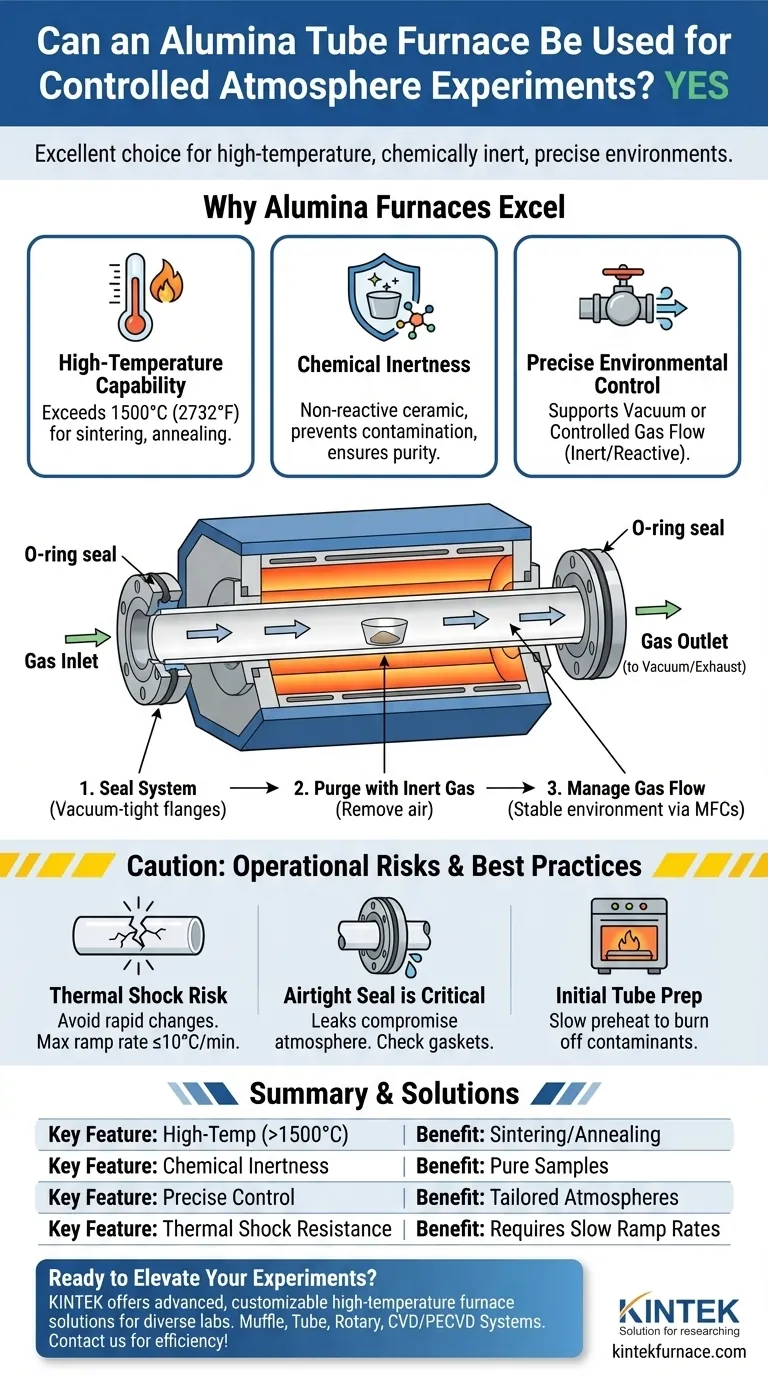

Why Alumina Furnaces Excel in Controlled Atmospheres

Alumina tube furnaces combine several key features that make them ideal for processing sensitive materials in non-ambient conditions.

High-Temperature Capability

The core of the furnace is the alumina (Aluminum Oxide, Al₂O₃) tube, which possesses exceptional thermal stability. This allows these furnaces to operate consistently at very high temperatures, often exceeding 1500°C (2732°F), which is critical for many heat treatment, sintering, and annealing processes.

Chemical Inertness

Alumina is a highly stable ceramic that is chemically inert. This means it will not react with or contaminate the samples being processed, even at extreme temperatures. This purity is essential for research and production where material integrity is paramount.

Precise Environmental Control

The furnace system is designed to be sealed. This allows for two primary methods of atmospheric control: creating a vacuum to remove ambient air (specifically oxygen and moisture) or introducing a controlled flow of inert or reactive gases to create a specific processing environment.

How a Controlled Atmosphere is Achieved

Creating a controlled atmosphere is a systematic process that relies on the furnace's integrated components.

Sealing the System

To control the internal atmosphere, the tube must first be isolated from the outside air. This is accomplished using vacuum-tight sealing flanges at both ends of the tube, which are typically equipped with ports for gas lines and vacuum pumps.

Purging with Inert Gas

The most common application is preventing oxidation. After sealing the tube, a vacuum pump is often used to evacuate the ambient air. Then, an inert gas, such as argon or nitrogen, is flowed into the tube to establish a positive-pressure, oxygen-free environment.

Managing Gas Flow

For processes requiring a continuous supply of fresh gas, the furnace is equipped with gas flow controllers. These can range from simple rotameters to precise mass flow controllers (MFCs) that ensure a stable and repeatable atmospheric condition throughout the experiment.

Understanding the Trade-offs and Operational Risks

While powerful, alumina tube furnaces require careful handling. The primary component subject to failure—the alumina tube itself—is a brittle ceramic.

The Critical Risk of Thermal Shock

Alumina tubes can crack if heated or cooled too quickly. It is critical to adhere to the manufacturer's recommended ramp rates, which should generally not exceed 10°C per minute. Abrupt temperature changes create thermal stress that will permanently damage the tube.

Ensuring an Airtight Seal

The effectiveness of your controlled atmosphere depends entirely on the quality of your seal. Even a small leak in a flange gasket can compromise an inert environment by allowing oxygen to enter the tube, potentially ruining an experiment. Always check seals before starting a high-temperature run.

Initial Tube Preparation

For first-time use or after a long period of inactivity, a new alumina tube should be conditioned. This involves a slow preheating cycle (e.g., 5-8°C/min up to 1300°C) to burn off any residual pollutants and relieve internal manufacturing stresses, ensuring a cleaner processing environment.

Making the Right Choice for Your Experiment

To use an alumina tube furnace effectively, align your procedure with your primary experimental goal.

- If your primary focus is preventing oxidation: Your top priority is a thorough purge cycle—evacuate the air and then backfill with a high-purity inert gas.

- If your primary focus is material purity: Pay close attention to the initial tube conditioning to burn off contaminants before inserting your valuable samples.

- If your primary focus is equipment longevity and safety: Strictly adhere to the recommended slow heating and cooling rates to prevent cracking the alumina tube.

Properly managed, an alumina tube furnace is a reliable and powerful tool for achieving precise control over your high-temperature processes.

Summary Table:

| Key Feature | Benefit for Controlled Atmosphere |

|---|---|

| High-Temperature Capability (up to 1500°C) | Enables sintering, annealing, and other high-heat processes in controlled environments. |

| Chemical Inertness | Prevents sample contamination, ensuring material purity during experiments. |

| Precise Environmental Control | Supports vacuum or gas flow for tailored atmospheres like inert or reactive gases. |

| Sealed System with Flanges | Allows airtight isolation and integration with gas/vacuum components for stability. |

| Thermal Shock Resistance (with care) | Requires slow ramp rates (e.g., ≤10°C/min) to avoid tube damage and ensure longevity. |

Ready to elevate your controlled atmosphere experiments with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our alumina tube furnaces can enhance your research efficiency and outcomes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents