Precise temperature control in a double tube high-temperature furnace is achieved through the strategic integration of high-power heating elements with programmable regulation systems. This combination allows for strict adherence to linear heating rates, such as 5°C per minute, ensuring the internal environment consistently matches the required parameters up to a maximum operating temperature of 1200°C.

Core Takeaway: The value of this precision lies not just in reaching high temperatures, but in the controlled journey to get there. By maintaining exact heating rates, researchers can isolate the effects of specific temperature variables (e.g., 500°C vs. 700°C), which is the technical key to optimizing biochar yield, carbon content, and microstructural integrity.

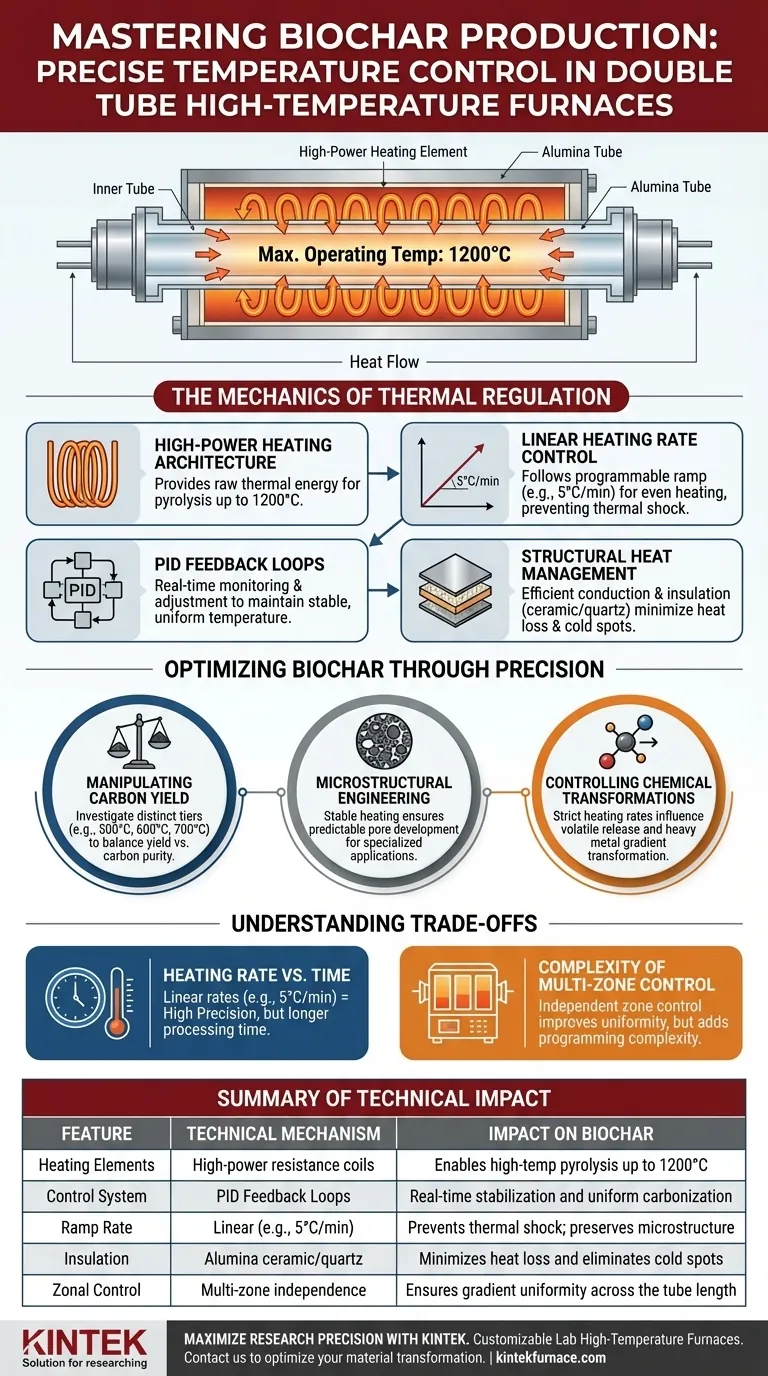

The Mechanics of Thermal Regulation

High-Power Heating Architecture

To achieve temperatures as high as 1200°C, the furnace relies on high-power heating elements.

These components provide the raw thermal energy necessary to drive the pyrolysis process. However, raw power alone results in fluctuations; it serves as the baseline capacity that allows the control systems to function effectively.

Linear Heating Rate Control

The defining feature of this equipment is its ability to execute linear temperature increases.

Instead of heating the biomass erratically, the system follows a programmable ramp, such as the 5°C per minute rate highlighted in testing protocols. This linearity ensures that the biomass is exposed to heat evenly, preventing thermal shock or uneven carbonization that could skew data on yield and composition.

PID Feedback Loops

To maintain the set linear rate, these furnaces utilize PID (Proportional-Integral-Derivative) control systems.

While the heating elements provide energy, the PID controller continuously monitors the internal temperature against the setpoint. It automatically adjusts the power output in real-time to correct deviations, ensuring the temperature remains stable and uniform throughout the heating duration.

Structural Heat Management

The physical design aids precision through efficient conduction and insulation.

Advanced designs often integrate alumina ceramic tubes within quartz structures and utilize high-performance insulation. This prevents heat loss to the exterior and ensures that the thermal energy generated by the coils is directed entirely toward the biomass sample, minimizing cold spots within the heating zone.

Optimizing Biochar Through Precision

Manipulating Carbon Yield

Precise control allows operators to investigate distinct pyrolysis tiers, typically 500°C, 600°C, and 700°C.

By holding these temperatures accurately, researchers can determine exactly how thermal intensity dictates the final mass of the biochar. This data is essential for balancing the trade-off between the quantity of biochar produced (yield) and its quality (carbon purity).

Microstructural Engineering

The microstructural characteristics of biochar are highly sensitive to thermal fluctuations.

A stable heating environment serves as the technical foundation for optimizing these physical properties. Consistent heat ensures that pore development and surface functional groups form predictably, which is critical if the biochar is intended for specialized applications like filtration or soil amendment.

Controlling Chemical Transformations

Strict adherence to heating rates (e.g., 5°C/min or slower rates like 1.2°C/min) influences the volatilization of impurities.

Slow, controlled heating allows for the gradual release of volatiles and the gradient transformation of heavy metals. This prevents the rapid agglomeration of material and ensures that the chemical structure of the lignocellulosic biomass transforms uniformly.

Understanding the Trade-offs

Heating Rate vs. Processing Time

While linear rates like 5°C/min offer high precision for research, they significantly increase processing time.

In a production context, there is often pressure to use faster rates (e.g., 60°C/min). However, accelerating the process can compromise the uniformity of pore formation and may lead to different chemical interactions compared to slow pyrolysis.

Complexity of Multi-Zone Control

Achieving uniformity across the entire tube length can be challenging.

Some furnaces employ multi-temperature zone designs to mitigate this, allowing independent control of different sections. While this improves accuracy, it introduces complexity in programming and calibration. A failure to synchronize these zones correctly can lead to temperature gradients that skew results.

Making the Right Choice for Your Goal

To maximize the utility of a double tube high-temperature furnace, align your settings with your specific objectives:

- If your primary focus is fundamental research: Prioritize slow, linear heating rates (e.g., 1.2°C to 5°C per minute) to meticulously map the relationship between temperature and heavy metal volatilization or carbon structure.

- If your primary focus is material throughput: Utilize higher heating rates (e.g., up to 60°C/min) but ensure your furnace is equipped with high-performance insulation and PID self-tuning to mitigate the risk of thermal instability.

- If your primary focus is surface chemistry: Maintain strict holding times at specific tiers (e.g., 600°C) to ensure complete aromatization and the proper formation of functional groups.

True optimization is achieved when you treat temperature not just as a target number, but as a precisely shaped variable that defines the material identity of your biochar.

Summary Table:

| Feature | Technical Mechanism | Impact on Biochar |

|---|---|---|

| Heating Elements | High-power resistance coils | Enables high-temp pyrolysis up to 1200°C |

| Control System | PID Feedback Loops | Real-time stabilization and uniform carbonization |

| Ramp Rate | Linear (e.g., 5°C/min) | Prevents thermal shock; preserves microstructure |

| Insulation | Alumina ceramic/quartz | Minimizes heat loss and eliminates cold spots |

| Zonal Control | Multi-zone independence | Ensures gradient uniformity across the tube length |

Maximize Your Research Precision with KINTEK

Don't let thermal fluctuations compromise your biochar yield or microstructural integrity. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temperature furnaces are fully customizable to meet your specific research or production needs.

Ready to optimize your material transformation? Contact us today to discuss your custom furnace requirements.

Visual Guide

References

- Caio Henrique da Silva, Wardleison Martins Moreira. Synthesis of Activated Biochar from the Bark of Moringa oleifera for Adsorption of the Drug Metronidazole Present in Aqueous Medium. DOI: 10.3390/pr12030560

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is the application scope of vertical fluidized bed tube furnaces expected to evolve? Discover Future Innovations in Precision Heating

- Why is a High-Temperature Vacuum Tube Furnace required for the long-term homogenization of alloy ingots?

- What features ensure precise temperature control in tube furnaces? Discover the Key Components for Accuracy

- What applications is a Split Tube Furnace (Single Zone) suitable for? Ideal for Uniform Heating and Easy Access

- What role does a horizontal tubular furnace play in VACNT synthesis? Master CVD Growth for High-Quality Nanotubes

- What role does a graphite tube heater play in the HPHT synthesis of Fe2B? Precision Heating for Metastable Materials

- What are the application areas of a 70mm tube furnace? Precision Heating for Materials Science and More

- What is the purpose of pre-treating sapphire substrates in a tube furnace? Optimize Your Epitaxial Growth Foundation