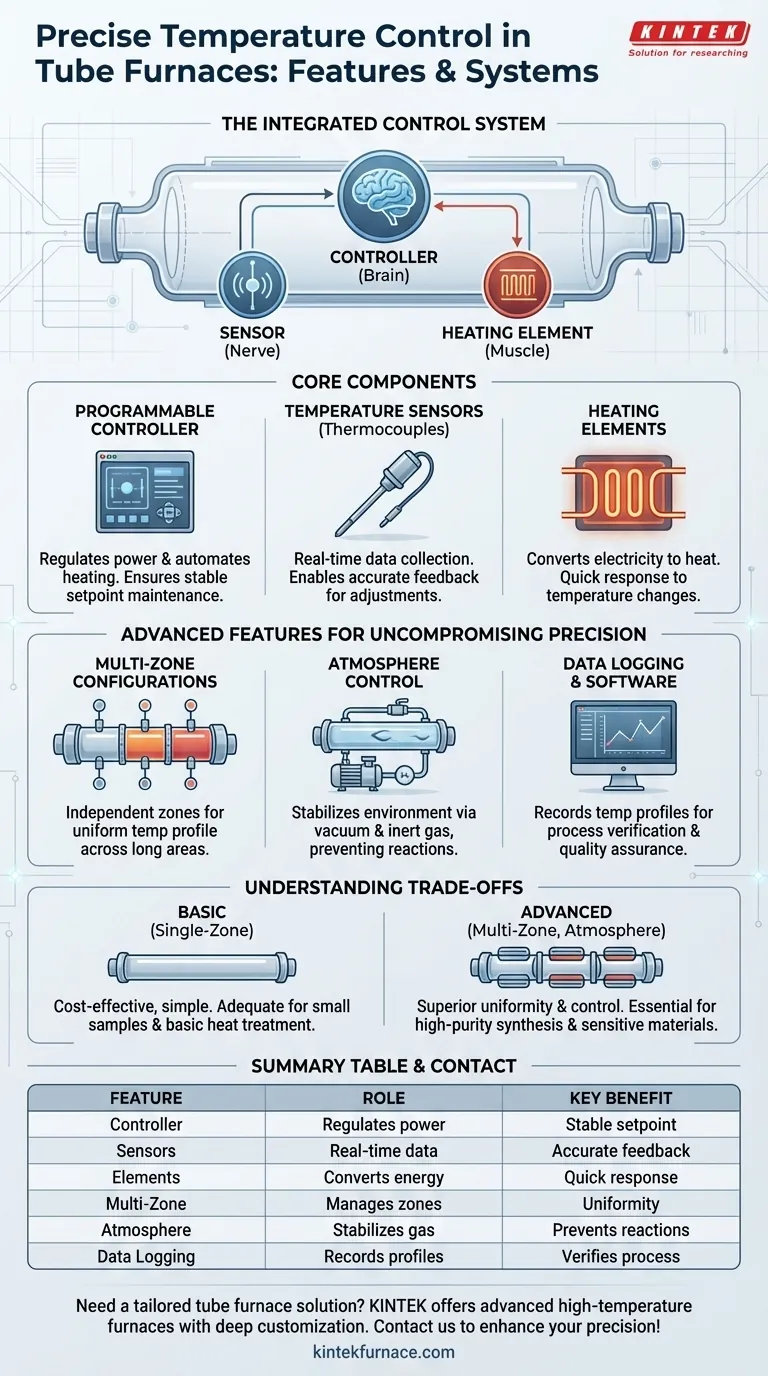

At its core, precise temperature control in a tube furnace is achieved through a coordinated system of three key components: a programmable temperature controller, accurate temperature sensors, and responsive heating elements. Advanced features like multi-zone configurations and atmosphere control further refine this precision by ensuring temperature uniformity along the tube and stabilizing the internal environment.

True precision in a tube furnace isn't about a single feature, but about an integrated control system. The controller acts as the brain, the sensor as the nerve, and the heating element as the muscle, all working in a continuous feedback loop to maintain a stable thermal environment.

The Core Components of Temperature Control

Achieving and maintaining a precise temperature is an active, continuous process. It relies on a feedback loop where the system constantly measures the temperature, compares it to the desired setpoint, and makes immediate corrections.

The Controller: The Brain of the Operation

The temperature controller is the central processing unit of the furnace. Modern furnaces use fully programmable digital controllers that automate the entire heating process.

These controllers regulate the power sent to the heating elements, adjusting it based on the feedback they receive from temperature sensors to maintain the exact temperature required by your process.

Temperature Sensors: The Eyes and Ears

A controller is useless without accurate data. Temperature sensors, typically thermocouples, are placed within the furnace to provide constant, real-time temperature readings.

The accuracy of these sensors is paramount. A high-quality sensor provides the reliable feedback necessary for the controller to make the minute adjustments that define precise temperature control.

Heating Elements: The Source of Thermal Energy

Heating elements are the components that convert electrical energy into heat. The controller precisely modulates the current flowing to these elements.

The responsiveness of the elements to these power adjustments dictates how quickly the furnace can react to deviations from the setpoint, preventing overshooting or undershooting the target temperature.

Advanced Features for Uncompromising Precision

For applications where temperature stability is critical—such as crystal growth, sintering, or annealing—basic control is not enough. Advanced features are required to ensure uniformity and eliminate external variables.

Multi-Zone Configurations: Ensuring Uniformity

A single-zone furnace has one controller and sensor pair managing the entire tube length, which can lead to cooler temperatures at the ends.

Multi-zone furnaces divide the tube into multiple independent heating zones. Each zone has its own dedicated controller and sensor, allowing the system to create a perfectly uniform temperature profile across a much longer area or even create a specific temperature gradient if needed.

Atmosphere Control: Stabilizing the Environment

The gas inside the furnace tube significantly impacts heat transfer and can react with your sample. Atmosphere control removes this variable.

By using sealed end caps, a vacuum pump can remove reactive gases like oxygen. Subsequently, a precise flow of a specific gas (like nitrogen or argon) can be introduced to create a stable, inert environment, ensuring consistent heating and preventing unwanted chemical reactions.

Data Logging and Software: Verifying the Process

While not a direct control feature, software that allows for data logging is crucial for quality assurance and repeatability.

This software records the temperature profile throughout the process, providing a verifiable record that the furnace maintained the precise temperature required. This is essential for validating results in research and manufacturing.

Understanding the Trade-offs

Choosing a furnace requires balancing precision with cost and complexity. Not every feature is necessary for every application.

Single-Zone vs. Multi-Zone Furnaces

A single-zone furnace is simpler, more affordable, and perfectly adequate for heating small samples or for processes where minor temperature variation at the ends of the tube is acceptable.

A multi-zone furnace provides superior temperature uniformity, making it essential for processing larger samples or for highly sensitive applications where every part of the sample must experience the exact same temperature. This precision comes at a higher cost and complexity.

Maximum Temperature vs. Cost

Furnaces are often rated by their maximum operating temperature (e.g., 1200°C, 1600°C, 1800°C). Higher temperatures require more advanced, durable, and expensive heating elements and insulation materials.

Consider the actual temperature your process requires. Selecting a furnace with a much higher temperature capability than you need results in unnecessary expense.

The Added Complexity of Atmosphere Control

Integrating vacuum pumps and gas mixing systems adds significant cost and operational complexity. However, for any process sensitive to oxidation or requiring a specific gaseous environment, this feature is not optional—it is fundamental to achieving the desired outcome.

Making the Right Choice for Your Process

The ideal set of features depends entirely on the demands of your specific application.

- If your primary focus is basic heat treatment or small, forgiving samples: A single-zone furnace with a reliable digital controller is a cost-effective and sufficient choice.

- If your primary focus is high-purity synthesis, crystal growth, or annealing long parts: You must prioritize a multi-zone configuration to guarantee the necessary temperature uniformity.

- If your primary focus is a process sensitive to oxidation or requiring specific reactions: Atmosphere control through vacuum and/or inert gas capabilities is non-negotiable for success.

Ultimately, understanding how these systems work together empowers you to select the right tool to achieve repeatable, high-quality results for your specific goal.

Summary Table:

| Feature | Role in Temperature Control | Key Benefit |

|---|---|---|

| Programmable Controller | Regulates power and automates heating | Ensures stable setpoint maintenance |

| Temperature Sensors | Provides real-time temperature data | Enables accurate feedback for adjustments |

| Heating Elements | Converts electricity to heat | Allows quick response to temperature changes |

| Multi-Zone Configurations | Manages independent heating zones | Achieves uniform temperature across the tube |

| Atmosphere Control | Stabilizes internal gas environment | Prevents reactions and ensures consistent heating |

| Data Logging Software | Records temperature profiles | Verifies process repeatability and quality |

Need a tube furnace tailored to your lab's precision requirements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet unique experimental needs for diverse laboratories. Contact us today to enhance your temperature control and achieve reliable results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis