To clean a quartz heating element, you must use only a soft cloth lightly dampened with plain water. After ensuring the appliance is unplugged and the element is completely cool, gently wipe the quartz tube without applying pressure. It is absolutely critical to avoid all commercial cleansers, abrasive pads, and solvents, as they can cause permanent damage and lead to element failure.

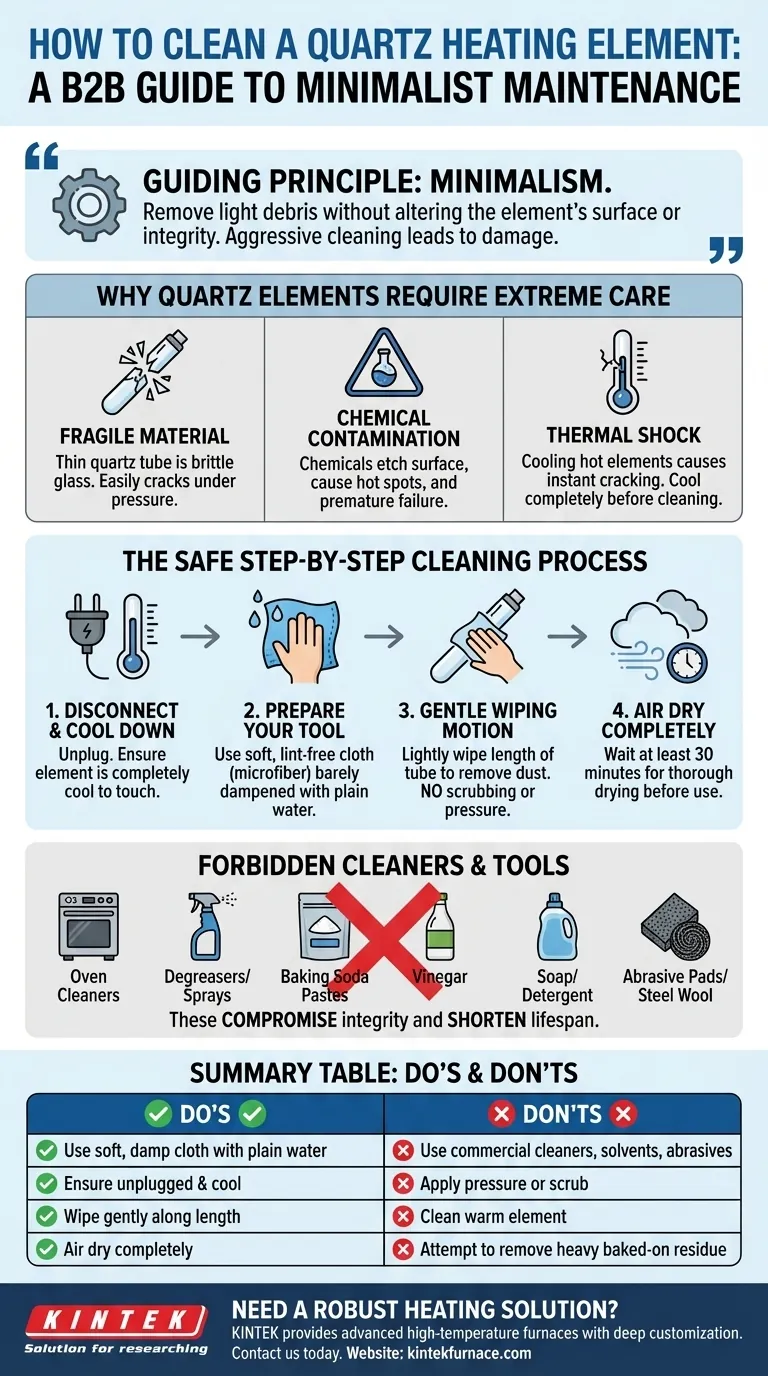

The guiding principle for cleaning a quartz heating element is minimalism. These components are extremely delicate, and the goal is to remove light debris without altering the element's surface or integrity. Aggressive cleaning will lead to damage, not a better result.

Why Quartz Elements Require Extreme Care

To clean these components safely, you must first understand why they are so sensitive. Their material properties and high-temperature function dictate a very specific approach.

The Material is Inherently Fragile

Quartz heating elements are typically made of a thin quartz tube protecting an inner coiled filament. This tube is essentially a form of glass. It is rigid and can withstand immense heat, but it is also brittle and will easily crack or shatter under physical pressure.

The Risk of Chemical Contamination

Never use oven cleaner, degreasers, or even mild soaps. Chemicals can etch the surface of the quartz, creating microscopic weak points. More importantly, any chemical residue left behind will burn onto the element when it heats up, creating hot spots that can cause the tube to crack and the element to fail prematurely.

The Danger of Thermal Shock

Applying a cool, damp cloth to a hot or even warm element can cause it to crack instantly. This phenomenon, known as thermal shock, occurs when one part of the material cools and contracts much faster than another. Always allow the appliance to cool completely for several hours before cleaning.

The Safe Step-by-Step Cleaning Process

Follow these steps precisely to clean the element without causing harm.

Step 1: Disconnect and Cool Down

Unplug the appliance from the wall outlet. This is a non-negotiable safety step. Allow the unit to sit until the quartz elements are completely cool to the touch.

Step 2: Prepare Your Cleaning Tool

Take a soft, lint-free cloth, such as a microfiber towel. Dampen a small section of it with plain water. Squeeze it out thoroughly until it is only slightly damp, not wet.

Step 3: Use a Gentle Wiping Motion

Gently wipe along the length of the quartz tube. Use a single, light pass to remove dust or loose debris. Do not scrub, apply pressure, or use a back-and-forth "sawing" motion.

Step 4: Air Dry Completely

Allow the element and the interior of the appliance to air dry completely before plugging it back in and using it. Wiping with a barely damp cloth should result in very fast drying, but it's wise to wait at least 30 minutes to be certain.

Understanding the Limitations and Pitfalls

Many people damage their appliances by attempting to do too much. Knowing what to avoid is as important as knowing what to do.

The Myth of a "Deep Clean"

If a quartz element has significant, black, carbonized food baked onto it, it has likely become a permanent part of the surface. Attempting to scrape or scrub this off will almost certainly break the element. The goal of cleaning is maintenance—removing light dust and recent splatters—not cosmetic restoration.

Forbidden Cleaners and Tools

To be perfectly clear, you must never use any of the following on a quartz heating element:

- Oven cleaners

- All-purpose sprays or degreasers

- Baking soda pastes

- Vinegar

- Soap or detergent

- Abrasive sponges, scouring pads, or steel wool

Using any of these will compromise the element's integrity and dramatically shorten its lifespan.

A Note on "Mild Solvents"

While some manufacturer guides may vaguely mention "mild solvents," this can be misleading. Unless your specific appliance manual explicitly names a safe solvent (like isopropyl alcohol for a specific type of residue), you should always default to using only water. Water is the universal and safest option.

Making the Right Choice for Your Appliance

Your approach should be dictated by the condition of the element.

- If your primary focus is removing light dust or a minor, fresh splatter: A simple, gentle wipe with a water-dampened cloth is the correct and only necessary action.

- If your primary focus is removing heavily baked-on, carbonized residue: It is safer to leave it alone than to risk breaking the element by trying to remove it.

- If your primary focus is safety and longevity: Always default to the instructions in your appliance's user manual before attempting any cleaning.

Ultimately, preserving the function of your heating element is far more important than achieving a perfect cosmetic appearance.

Summary Table:

| Do's | Don'ts |

|---|---|

| Use a soft, damp cloth with plain water | Use commercial cleaners, solvents, or abrasives |

| Ensure the appliance is unplugged and cool | Apply pressure or scrub the element |

| Wipe gently along the length of the tube | Clean a warm element (risk of thermal shock) |

| Allow to air dry completely before use | Attempt to remove heavily baked-on residue |

Need a robust heating solution built for your specific lab conditions? At KINTEK, we understand that delicate components like quartz heating elements require precise handling and reliable performance. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today (#ContactForm) to discuss how our durable, tailored heating systems can enhance your lab's efficiency and safety.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer